Environment-friendly waste asphalt mixture regenerant with solubilizing effect and preparation method of environment-friendly waste asphalt mixture regenerant

A waste asphalt, environmentally friendly technology, applied in the field of asphalt pavement materials, can solve the problems of poor thermal stability and permeability of regenerants, restrictions on asphalt pavement regeneration technology, and increased stiffness modulus of mixtures, etc., to improve the internal chemical composition and structure, improving and stabilizing the colloidal structure of asphalt, and improving the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

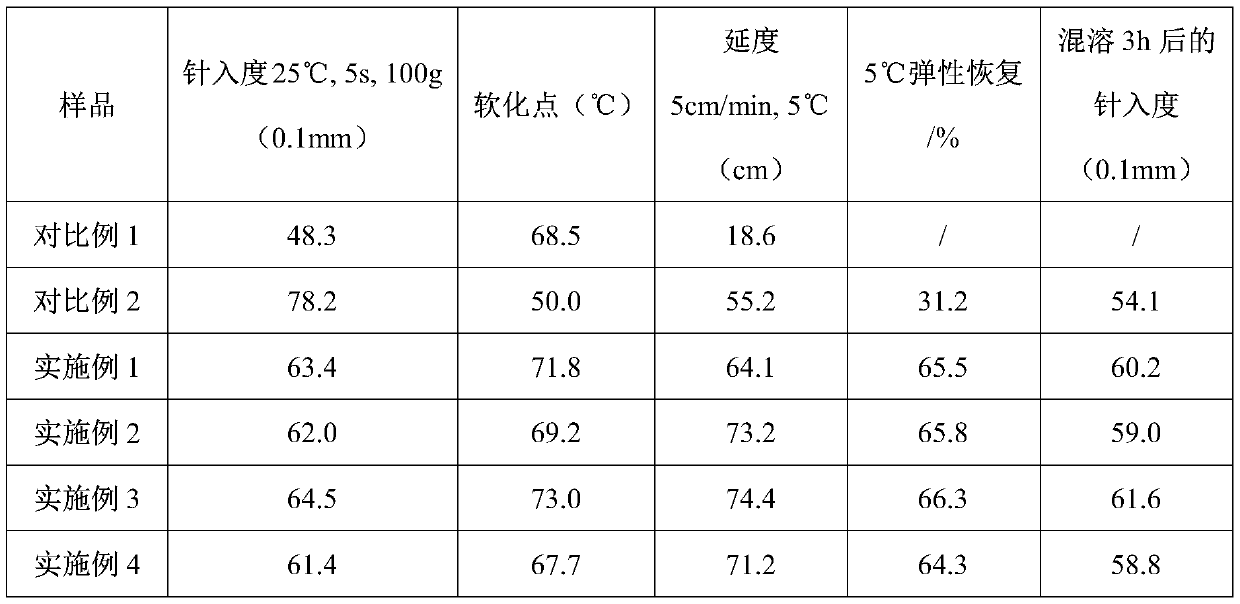

Examples

preparation example Construction

[0028] The preparation method of the environment-friendly waste asphalt mixture regeneration agent with solubilizing effect of the present invention comprises the following steps:

[0029] 1) waste and old rubber powder is carried out microwave treatment;

[0030] 2) mixing and stirring the catalytic cracking oil slurry, waste epoxidized soybean oil, sodium dodecylbenzenesulfonate and polyisobutenyl succinimide to obtain a mixture;

[0031] 3) heating the mixture obtained in step 2), then adding polyisobutylene maleic acid amide, hindered amine light stabilizer and isobutyltriethoxysilane in sequence, and then stirring;

[0032] 4) Heat the mixture obtained in step 3) to 120°C, then add the waste rubber powder treated in step 1), and stir at 120°C for 40 minutes to obtain an environmentally friendly waste asphalt mixture regenerant with solubilizing effect.

[0033] The specific operation of step 1) is: microwave treatment of waste rubber powder under 600w power for 1h;

[0...

Embodiment 1

[0037] The environmentally friendly waste and old asphalt mixture regeneration agent with solubilizing effect of the present invention consists of 14.7% waste rubber powder, 70% oil, 4% solubilizer, 3% polyisobutylene maleic acid amide, Prepared with 2.3% hindered amine light stabilizer and 6% isobutyltriethoxysilane.

[0038] The oil component is composed of 70% by mass percentage of catalytic cracking oil slurry and 30% of waste epoxidized soybean oil.

[0039] The relative density of the catalytic cracking oil slurry is 1.161, and the catalytic cracking oil slurry is composed of 70% aromatics, 15% saturates, 9% colloids and 6% asphaltenes by mass percentage; It is obtained after frying for 1 hour and filtering the residue. The initial epoxy value is greater than 8%.

[0040] The mass percentage of the solubilizer is composed of 65% sodium dodecylbenzenesulfonate and 35% polyisobutenyl succinimide.

[0041] The waste rubber powder is the waste car tire powder after desulfu...

Embodiment 2

[0052] The environmentally friendly waste and old asphalt mixture regeneration agent with solubilizing effect of the present invention consists of 17% waste rubber powder, 60% oil, 8% solubilizer, 5% polyisobutylene maleic acid amide, Prepared with 3.1% hindered amine light stabilizer and 6.9% isobutyltriethoxysilane.

[0053] The oil component is composed of 60% by mass percentage of catalytic cracking oil slurry and 40% of waste epoxidized soybean oil.

[0054] The relative density of the catalytic cracking oil slurry is 1.161, and the catalytic cracking oil slurry is composed of 70% aromatics, 15% saturates, 9% colloids and 6% asphaltenes by mass percentage; It is obtained after frying for 1 hour and filtering the residue. The initial epoxy value is greater than 8%.

[0055] The mass percentage of the solubilizer is composed of 55% sodium dodecylbenzenesulfonate and 45% polyisobutenyl succinimide.

[0056] The waste rubber powder is the waste car tire powder after desulfu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com