Urease-nanogold composite material with adjustable urease activity as well as preparation method and application of composite material

A technology of composite materials and urease activity, applied in biochemical equipment and methods, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as complexity, bulkiness, and low detection efficiency, and achieve an improved degree of decomposition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Preparation of hollow porous nano gold

[0022] Add 640μL of 28mM hydroquinone to 18mL, 90mM PVP solution, add 40μL, 60mM AgNO 3 After the solution is protected from light, add 640μL of 25mM chloroauric acid drop by drop, shake while adding, shake vigorously for 5min and then let stand for 60min, add 200μL of concentrated ammonia water, react in a shaker at 37℃ for 2h, centrifuge and disperse into 2mL water to obtain 1.5mg / mL of porous hollow nano-gold solution.

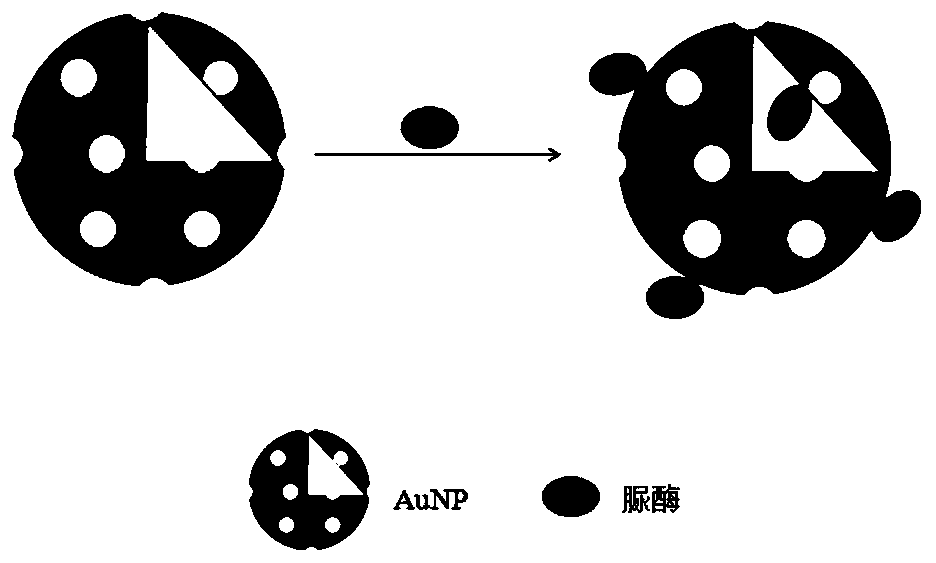

[0023] (2) Synthesis of gold nanoparticles modified by urease

[0024] Add 240 μL of the nano-gold solution obtained in step (1) to 360 μL, 1 mg / mL urease, mix and shake overnight, and centrifuge to obtain urease-functionalized nano-gold.

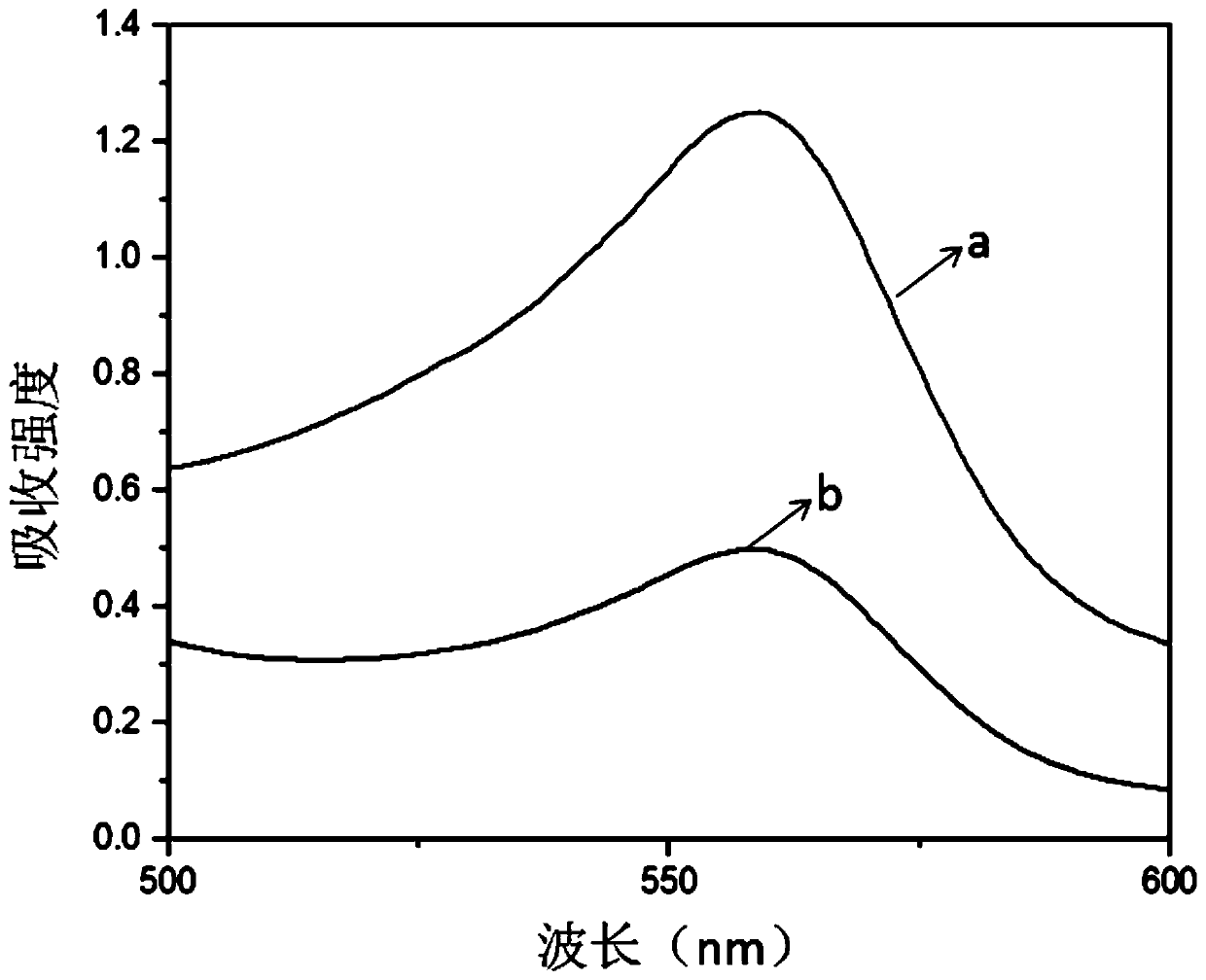

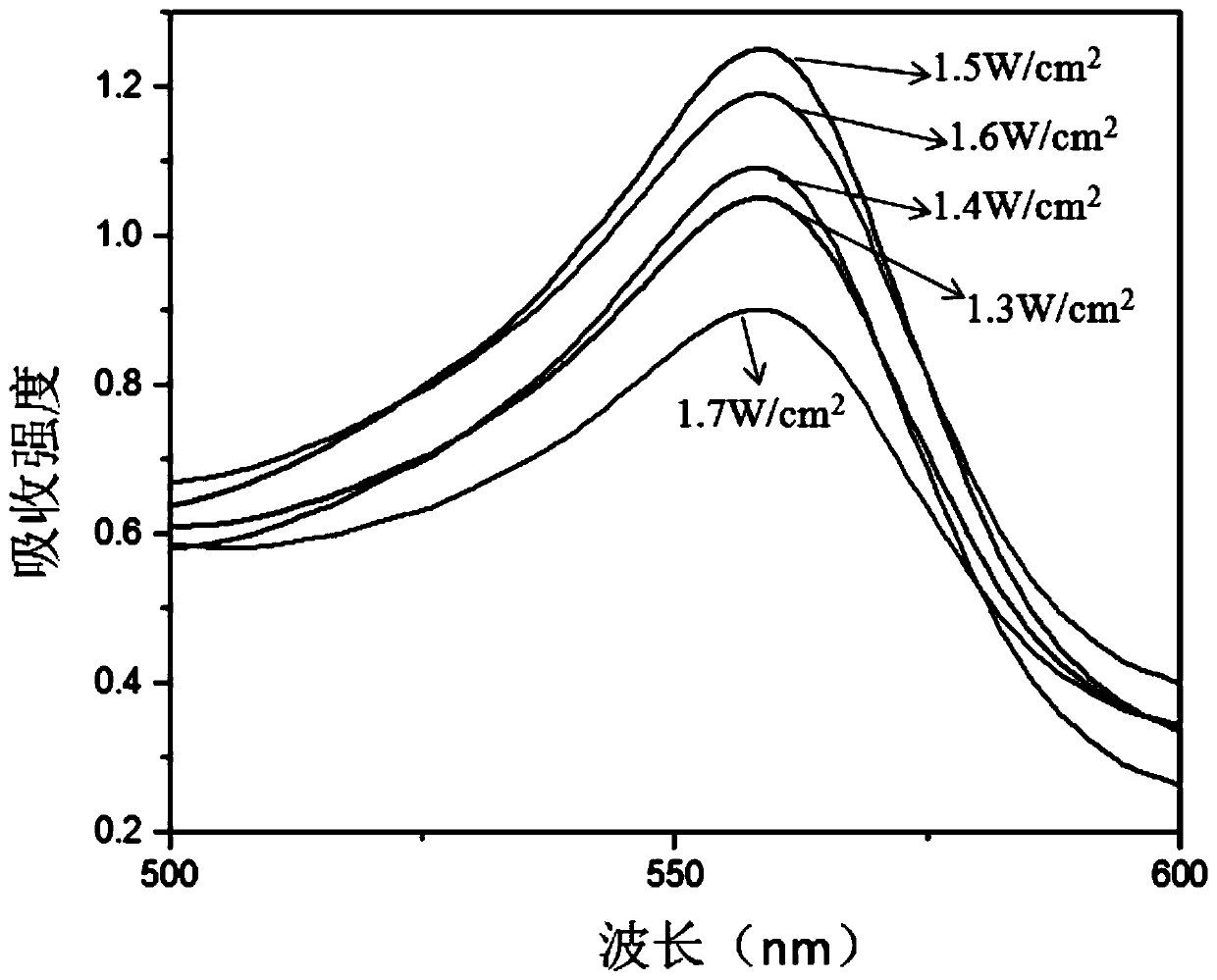

[0025] (3) Light and heat control urease activity

[0026] Use with a power of 1.5W / cm 2 The near-infrared light with a wavelength of 808nm irradiates the urease-modified gold nanospheres and a separate urease solution for 10 minutes, and the results are as follows figure 2 As...

Embodiment 2

[0029] (1) Preparation of hollow porous nano gold

[0030] Add 600μL of 30mM hydroquinone to 17mL, 100mM PVP solution, add 50μL, 50mM AgNO 3 After the solution is protected from light, add 600μL of 30mM chloroauric acid drop by drop, shake while adding, shake vigorously for 6min and let stand for 70min, add 300μL of 12mM concentrated ammonia water, react in a shaker at 35℃ for 3h, centrifuge and disperse into 1.5mL water to obtain 2mg / mL of porous hollow nano-gold solution.

[0031] (2) Synthesis of gold nanoparticles modified by urease

[0032] Add 300 μL of the nano-gold solution obtained in step (1) to 400 μL, 1.5 mg / mL urease, mix and shake overnight, and centrifuge to obtain urease-functionalized gold nanoparticles.

Embodiment 3

[0034] (1) Preparation of hollow porous nano gold

[0035] Add 700μL of 25mM hydroquinone to 19mL, 80mM PVP solution, add 30μL, 70mM AgNO 3 After the solution is protected from light, add 700μL of 20mM chloroauric acid drop by drop, shake while adding, shake vigorously for 4min and let stand for 50min, add 100μL of 14mM concentrated ammonia water, react at 40℃ shaker for 1h, centrifuge and disperse into 3mL water to obtain 1.0mg / mL of porous hollow nano-gold solution.

[0036] (2) Synthesis of gold nanoparticles modified by urease

[0037] Add 200 μL of the nano-gold solution obtained in step (1) to 300 μL, 0.5 mg / mL urease, mix and shake overnight, and centrifuge to obtain urease-functionalized nano-gold.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com