Transition metal in-situ doped TiO2 catalyst as well as preparation method and application thereof

A transition metal, in-situ doping technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the limitation of catalytic performance modulation and application range, The overall performance of the catalyst is greatly affected, and the distribution of metal atoms is not uniform, so that the experimental conditions are easy to control, the production cost is low, and the structure is stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

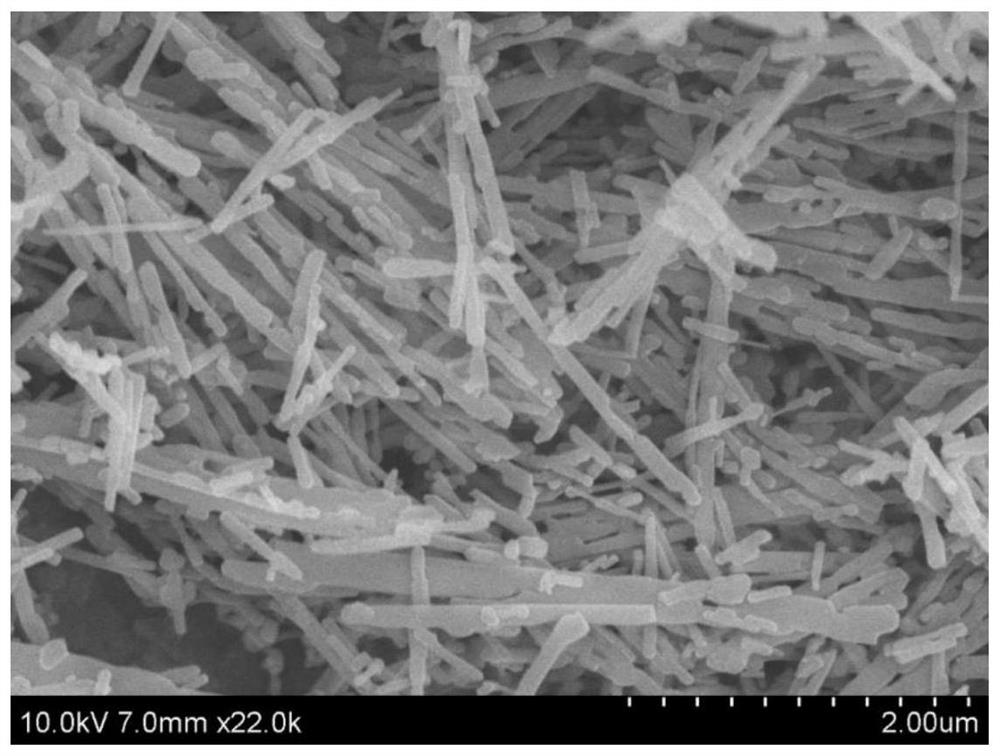

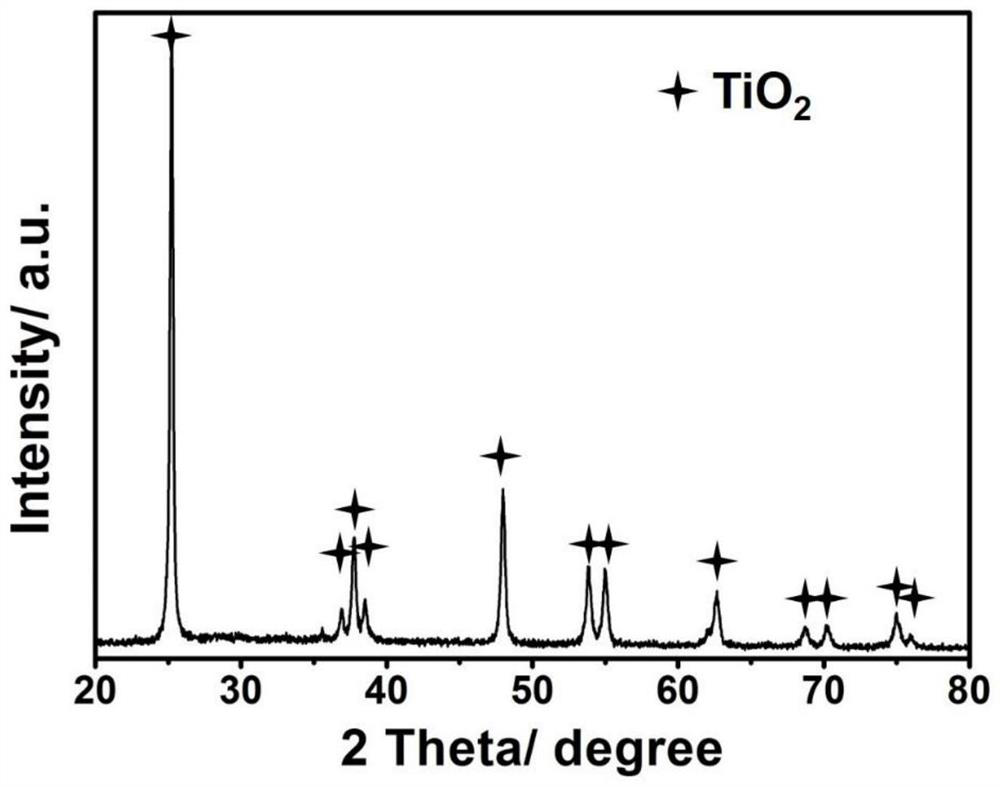

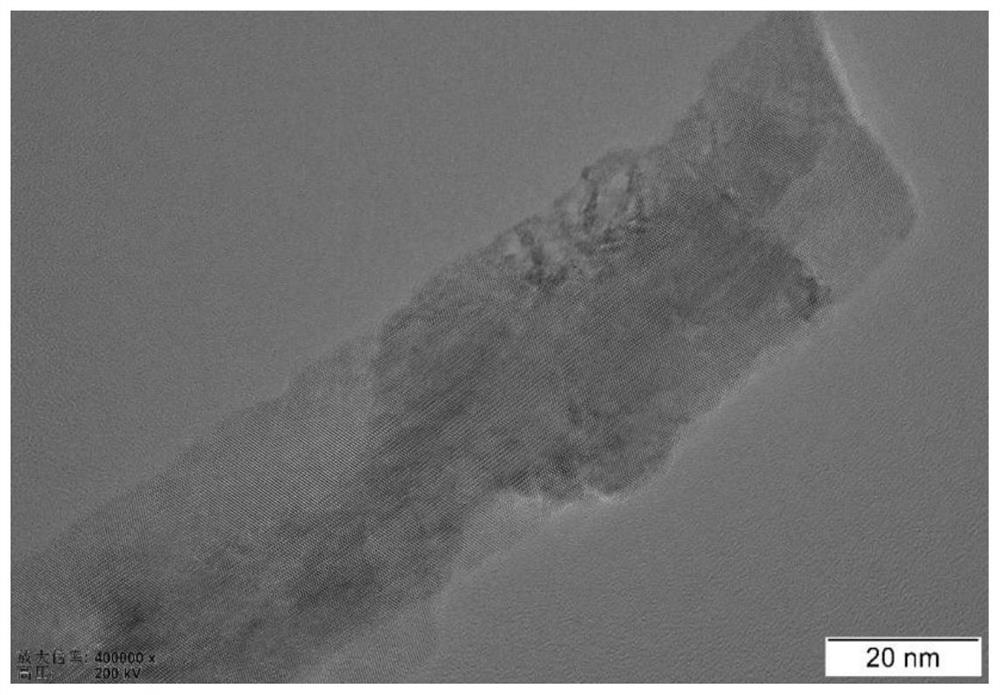

[0030] Weigh 0.1g of H 2 Ti 3 o 7 The raw material is added to 40 mL of an aqueous solution of cuprous chloride with a concentration of 0.1 mol / L under the assistance of ultrasound, and the ultrasound is continued for 5-10 minutes to obtain a uniformly dispersed suspension. The suspension was continuously stirred by magnetic force for 24 h at room temperature, and the H 2 Ti 3 o 7 H in + Ions and Cu in solution + The ion exchange reaches equilibrium, and the complete Cu exchange is obtained by filtration. x h 2- x Ti 3 o 7 The samples (x is the atomic ratio, 0x h 2-x Ti 3 o 7 The sample was calcined in a tube furnace, fed with air, and then the temperature was raised from room temperature to 700 °C at a rate of 5 °C / min, and kept at this temperature for 2 h, and then naturally cooled to room temperature, and the brown Cu atomic atoms were collected. Site-doped Cu-TiO 2 Catalyst, the XRD collection of patterns of gained material such as figure 1 As shown, it can...

Embodiment 2

[0032] Weigh 0.1g of H 2 Ti 3 o 7 The raw material is added to 50 mL of an aqueous solution of zinc acetate with a concentration of 0.1 mol / L under the assistance of ultrasound, and the ultrasound is continued for 5-10 minutes to obtain a uniformly dispersed suspension. The suspension was continuously stirred by magnetic force for 24 h at room temperature, and the H 2 Ti 3 o7 H in + Ions and Zn in solution 2+ The ion exchange reaches equilibrium, and the Zn that is completely exchanged is filtered x h 2- x Ti 3 o 7 The samples (x is the atomic ratio, 0x h 2-x Ti 3 o 7 The sample was calcined in a tube furnace, fed with air, and then the temperature was raised from room temperature to 800 °C at a rate of 10 °C / min, and kept at this temperature for 2 hours, then naturally cooled to room temperature, and gray-black Zn atoms were collected. In-situ doped Zn-TiO 2 catalyst.

Embodiment 3

[0034] Weigh 0.5g of H 2 Ti 3 o 7 The raw material is added to 100 mL of silver nitrate aqueous solution with a concentration of 0.05 mol / L under the assistance of ultrasound, and the ultrasound is continued for 5-10 minutes to obtain a uniformly dispersed suspension. The suspension was continuously stirred by magnetic force for 22 h at room temperature, and the H 2 Ti 3 o 7 H in + Ions and Ag in solution + The ion exchange reaches equilibrium, and the complete Ag exchange is obtained by filtration. x h 2- x Ti 3 o 7 The samples (x is the atomic ratio, 0x h 2-x Ti 3 o 7 The sample was calcined in a tube furnace, fed with air, and then the temperature was raised from room temperature to 750 °C at a rate of 5 °C / min, and kept at this temperature for 2 hours, and then naturally cooled to room temperature, and gray-blue Ag was collected. Atomically doped Ag-TiO 2 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com