A kind of metal fiber porous material prepared by bending structure aluminum alloy wire and its preparation method and application

A technology of metal fibers and porous materials, applied in the field of metal fiber porous materials and their preparation, can solve the problems of low strength, high closed porosity of aluminum porous materials, and little research, and achieves high strength, reduced operation steps, and light weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

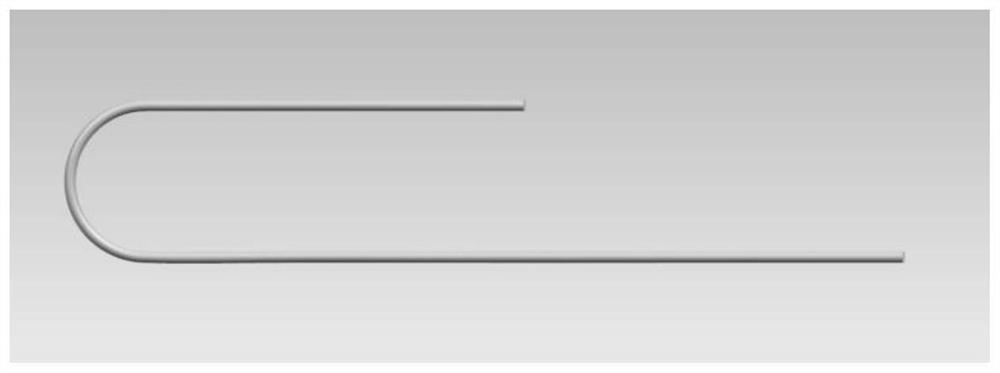

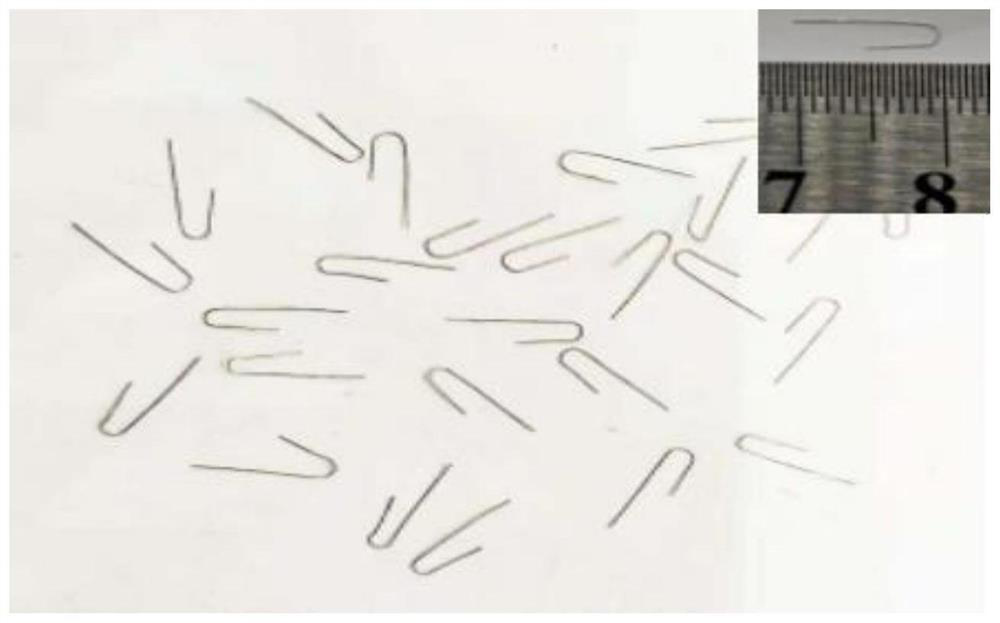

[0037] The bending structure 6061 aluminum alloy short wire (0.15 mm in diameter, 5 mm in length of the short side, 10 mm in length of the long side, and 2 mm in transition arc diameter) selected in this embodiment is used to prepare the metal fiber porous material, and the specific operation steps are as follows:

[0038] (1) According to the mass-volume method, as shown in formula (1), calculate the mass of the new-type bent structure aluminum alloy short wire corresponding to the porosity of 60%, and weigh 13.8 g of the corresponding quality bent structure aluminum alloy short wire; Spread it evenly in a special mold.

[0039] P(%)=(1-M / ρV)×100 Formula (1)

[0040] Wherein, P represents the target porosity, M represents the mass of the metal fiber porous material, ρ represents the density of the aluminum alloy, and V represents the volume of the prepared metal fiber porous material.

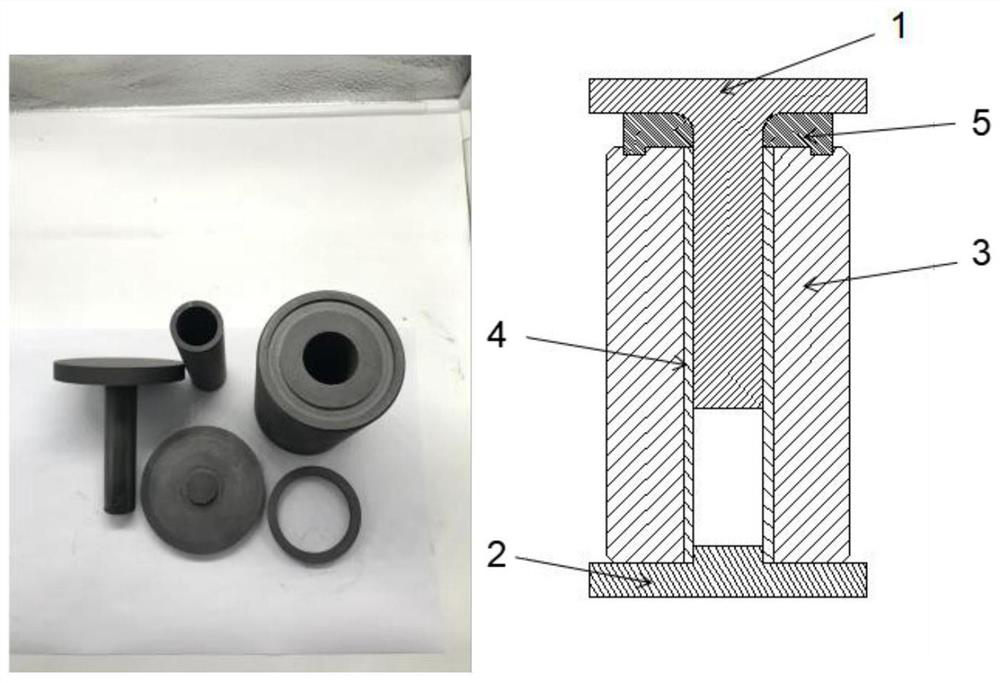

[0041] Among them, the structure of the special mold is as follows: image 3 As shown, t...

Embodiment 2

[0046] The preparation method is the same as that of Example 1, except that the mass of the bent aluminum alloy short wire described in step (1) is 10.4 g, and a metal fiber porous material with a required porosity of 70% is obtained.

Embodiment 3

[0048] The preparation method is the same as that of Example 1, except that the mass of the bent aluminum alloy short wire described in step (1) is 6.9 g, and a metal fiber porous material with a required porosity of 80% is obtained.

[0049] Figure 5 It is the physical picture of the metal fiber porous material prepared in Examples 1-3. Among them, from left to right are prepared metal fiber porous materials with porosities of 60%, 70%, and 80%. From Figure 5 It can be seen that the lower the porosity, the denser the prepared metal fiber porous material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com