A strong chemical adsorption interface thermal barrier coating bonding layer material and its preparation method

A chemical adsorption and thermal barrier coating technology, applied in the coating, metal material coating process, etc., can solve the problems of thermal barrier coating failure, ceramic layer shedding, and reduce the thermal service performance of the thermal barrier coating system, to achieve Enhance thermal service performance and solve the effect of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This embodiment provides a strong chemical adsorption interface thermal barrier coating bonding layer material, and a method for preparing a thermal barrier coating system using heat-resistant stainless steel 310S as the metal substrate to be protected, wherein the heat-resistant stainless steel 310S is austenitic Body stainless steel has good oxidation resistance and corrosion resistance. Because of the high percentage of chromium and nickel, it has good creep strength, can work continuously at high temperature, and has good high temperature resistance.

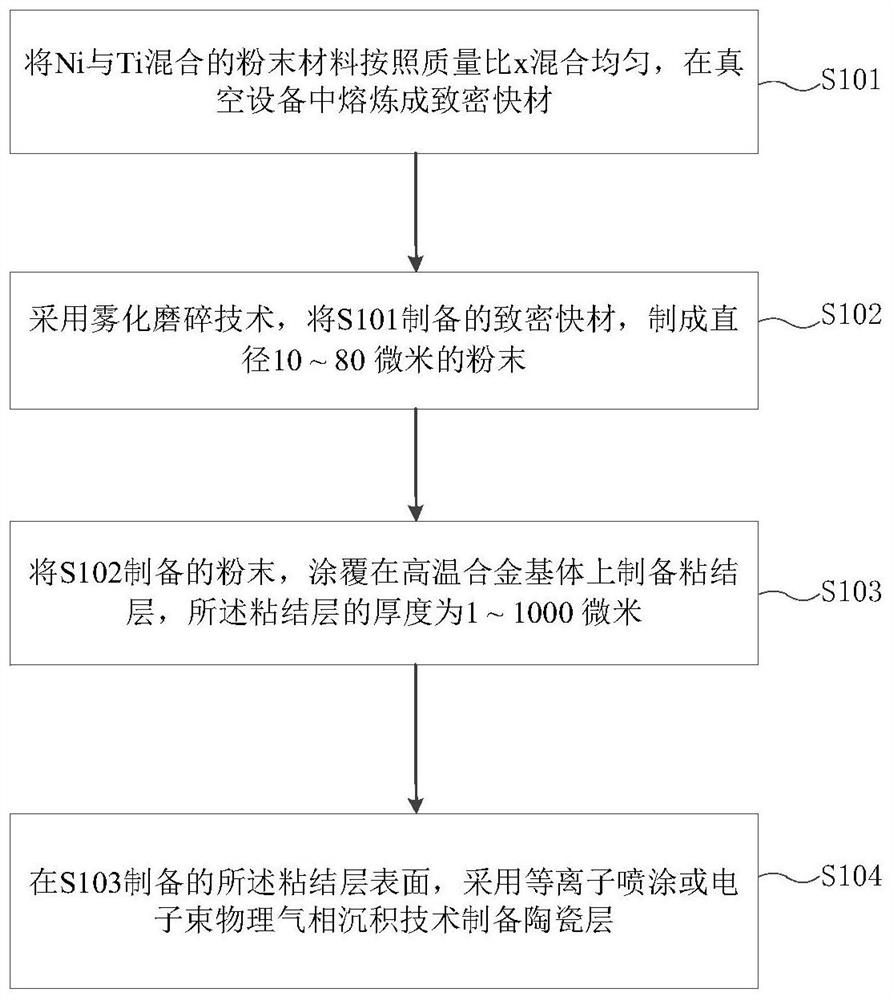

[0043] Such as image 3 As shown, the specific preparation steps are as follows:

[0044] S101: Mix the powder material mixed with Ni and Ti evenly according to the mass ratio x, and smelt it into a dense fast material in a vacuum device.

[0045] During specific implementation, the powder material mixed with Ni and Ti is uniformly mixed according to the mass ratio of 9:1, and smelted into a dense fast material in a ...

Embodiment 2

[0060] This embodiment provides a strong chemical adsorption interface thermal barrier coating bonding layer material, and a method for preparing a thermal barrier coating system with the superalloy K456 as the metal substrate to be protected, wherein the nickel-based superalloy K465 alloy has a relatively high High creep resistance, fatigue ability and high temperature bearing capacity.

[0061] The specific preparation steps for preparing the thermal barrier coating system are as follows:

[0062] The preparation methods of S101 and S102 are similar to those in Example 1, and will not be described in detail in this example. The difference is that the powder materials mixed with Ni and Ti are uniformly mixed at a mass ratio of 5:5.

[0063] S103: Coating the powder prepared in S102 on the superalloy substrate to prepare a bonding layer, the thickness of the bonding layer is 1-1000 microns.

[0064] During specific implementation, the prepared superalloy substrate material su...

Embodiment 3

[0072] This embodiment provides a strong chemical adsorption interface thermal barrier coating bonding layer material, and a method for preparing a thermal barrier coating system using heat-resistant stainless steel 310S as the metal substrate to be protected, wherein the heat-resistant stainless steel 310S is austenitic Body stainless steel has good oxidation resistance and corrosion resistance. Because of the high percentage of chromium and nickel, it has good creep strength, can work continuously at high temperature, and has good high temperature resistance.

[0073] The specific preparation steps for preparing the thermal barrier coating system are as follows:

[0074] The preparation method of S101 and S102 is similar to that of any one of Examples 1-2, and will not be repeated in this example. The difference is that the powder material mixed with Ni and Ti is 3:7 in mass ratio. The proportions are mixed evenly.

[0075] S103: Coating the powder prepared in S102 on the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com