LED epitaxial structure, manufacturing method thereof and LED chip

A technology of epitaxial structure and manufacturing method, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve problems affecting LED luminous efficiency, lattice mismatch, etc., achieve high luminous efficiency, less electron leakage, and reduce stress mismatch Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

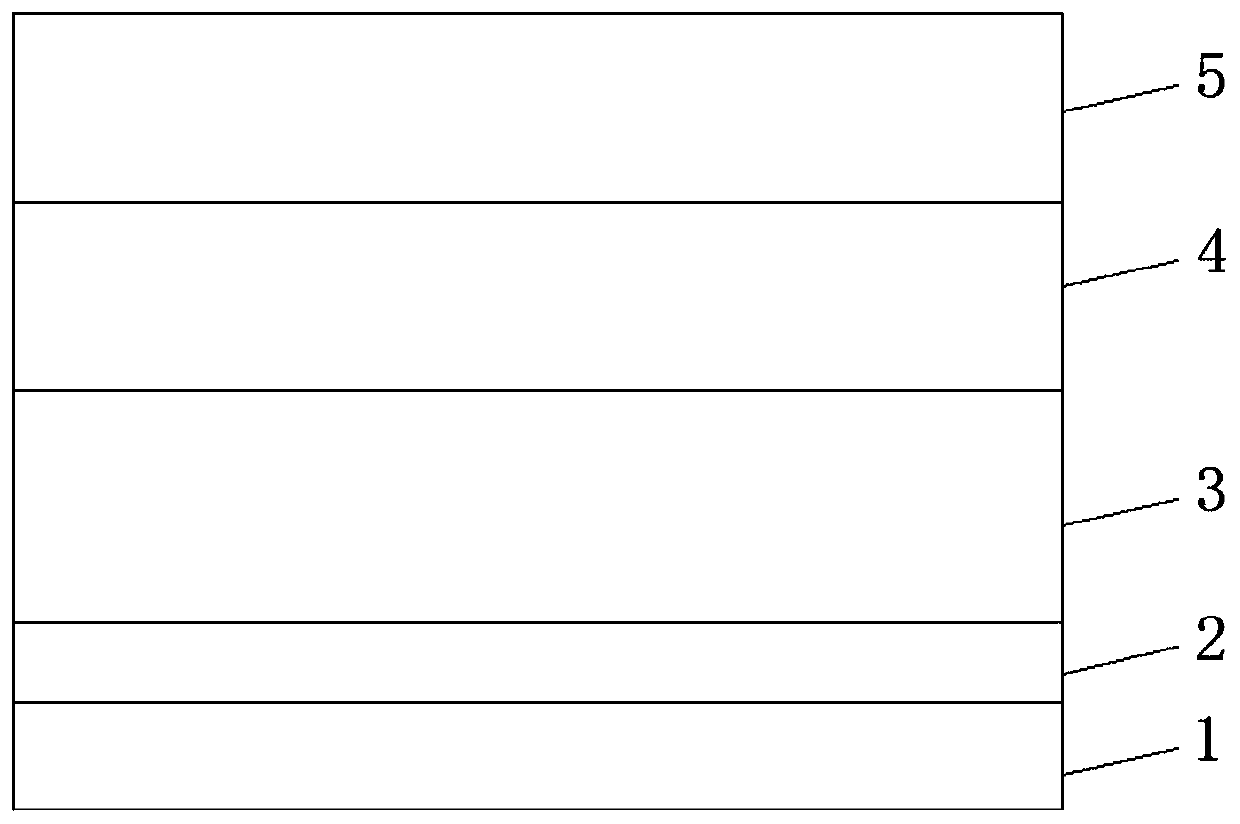

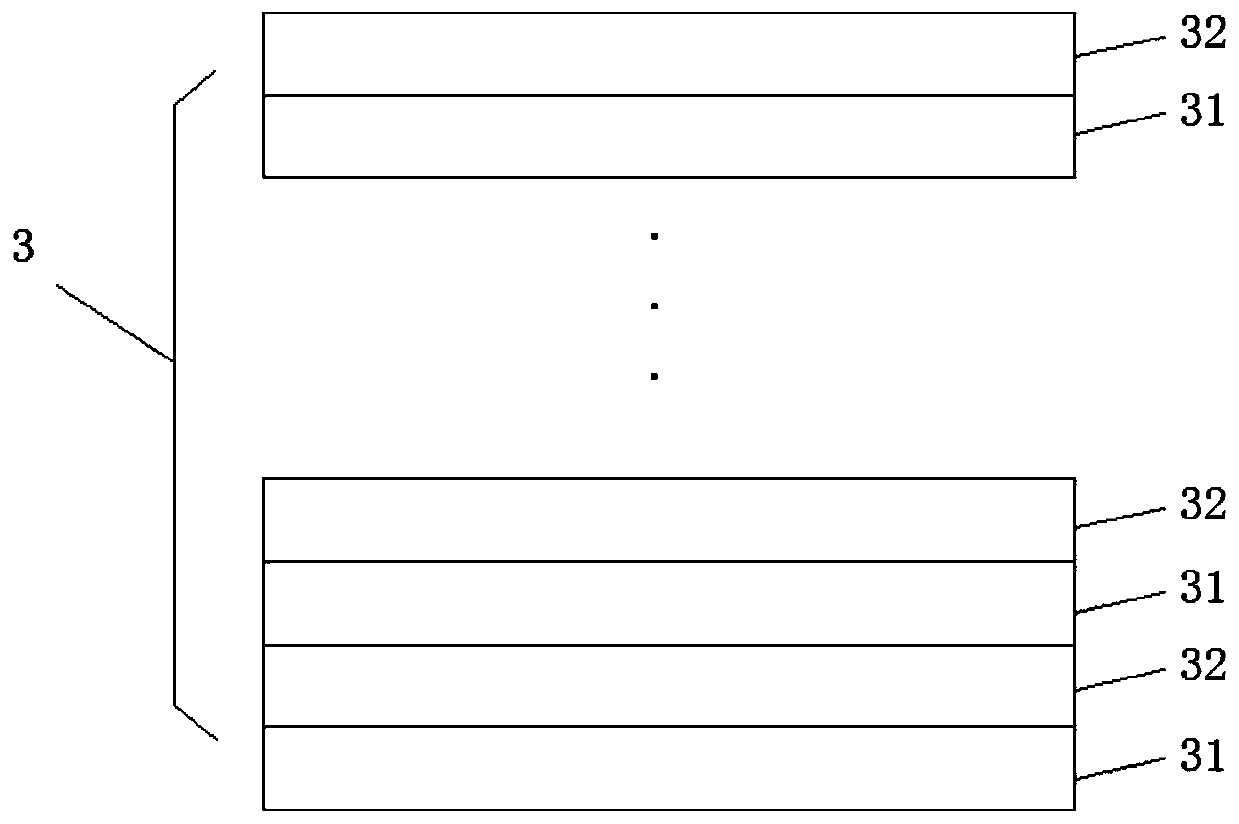

[0059] An LED epitaxial structure, including a substrate 1, a buffer layer 6, an undoped GaN layer 7, a first-type semiconductor layer 2, a multi-quantum well barrier layer 3, an electron blocking layer 4, and a second-type semiconductor layer 5 stacked in sequence , the multiple quantum well barrier layer 3 includes a quantum well 31 and a quantum barrier 32, wherein the buffer layer 6 is a GaN buffer layer, the first semiconductor layer 2 is an N-type GaN layer doped with Si, and the electron barrier Layer 4 is a P-type electron blocking layer, and the second-type semiconductor layer 5 is a P-type GaN layer. Please refer to figure 1 and figure 2 .

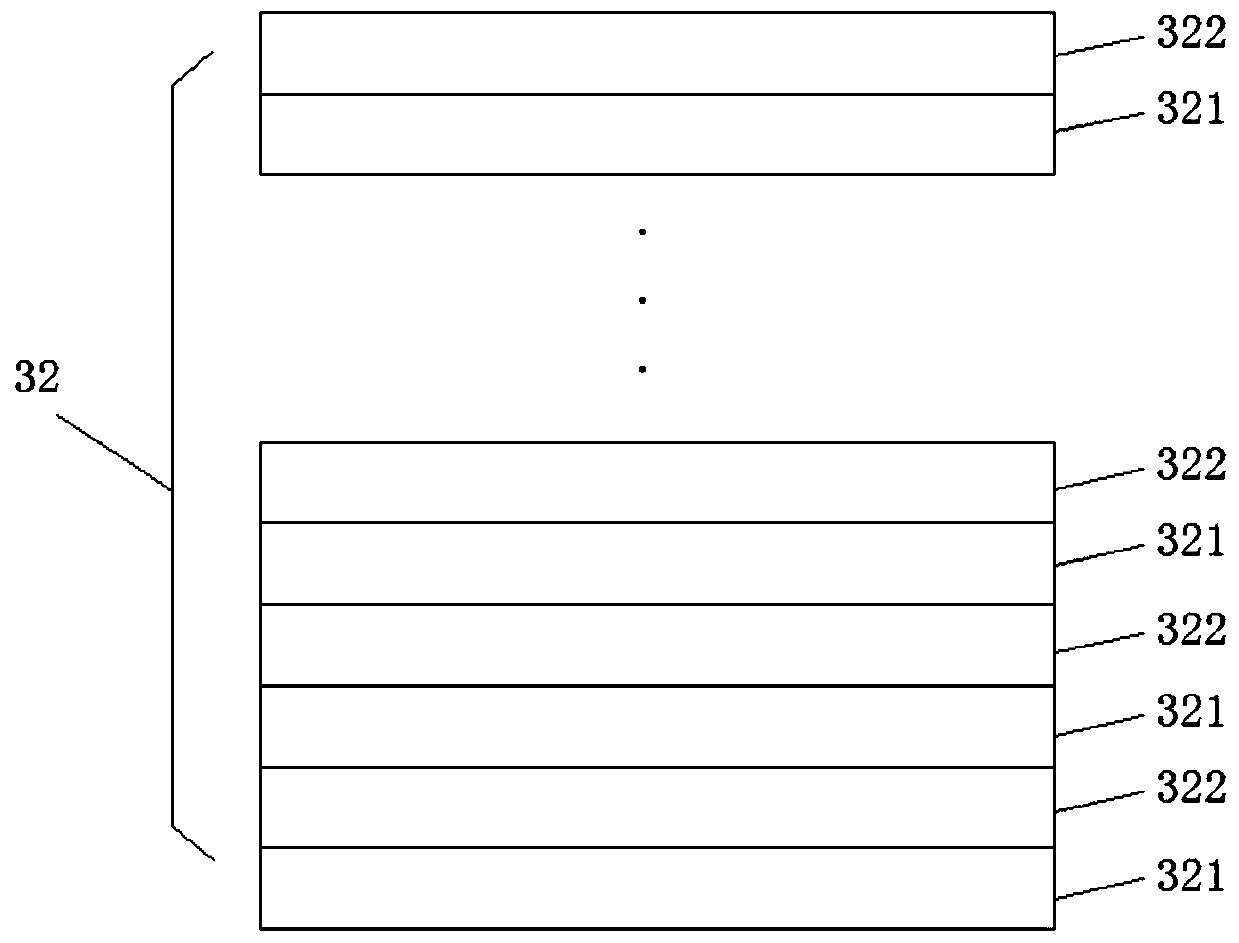

[0060] Please refer to image 3 , the quantum barrier 32 is an AlInGaN / AlGaN superlattice structure, the period of the AlInGaN / AlGaN superlattice structure is multiple, each period includes an AlInGaN layer 321 and an AlGaN layer 322, and the Al group of the AlInGaN layer 321 Minutes change as the number of periods increases...

Embodiment 2

[0064] An LED epitaxial structure, the difference from the first embodiment above is that the thickness of the AlInGaN / AlGaN superlattice structure decreases as the number of periods increases, please refer to Figure 7 . Wherein, the abscissa refers to the AlInGaN / AlGaN superlattice structure, and the ordinate refers to the thickness of the AlInGaN / AlGaN superlattice structure.

Embodiment 3

[0066] An LED epitaxial structure, the difference from the second embodiment above is that the AlInGaN / AlGaN superlattice structure has Si doping, and the change of Si doping concentration includes but not limited to: with the period of the AlInGaN / AlGaN superlattice structure increase or decrease gradually. Please refer to the specific change diagram Figure 8a and Figure 8b , where the abscissa refers to the AlInGaN / AlGaN superlattice structure, and the ordinate refers to the Si doping concentration of the AlInGaN / AlGaN superlattice structure. It should be noted, Figure 8a and Figure 8b It is only for illustration and not for limitation of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com