Preparation method of graphene heating film

A technology of ene heating film and graphene, which is applied in the field of preparation of graphene heating film, can solve problems such as difficulty in ensuring the uniformity of graphene heating film, decline in product stability and reliability, and poor adhesion of graphene heating film. Achieve high pressure resistance, long service life and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

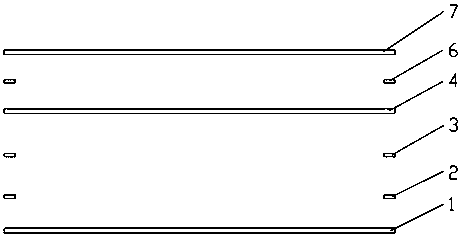

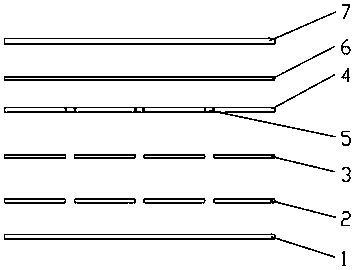

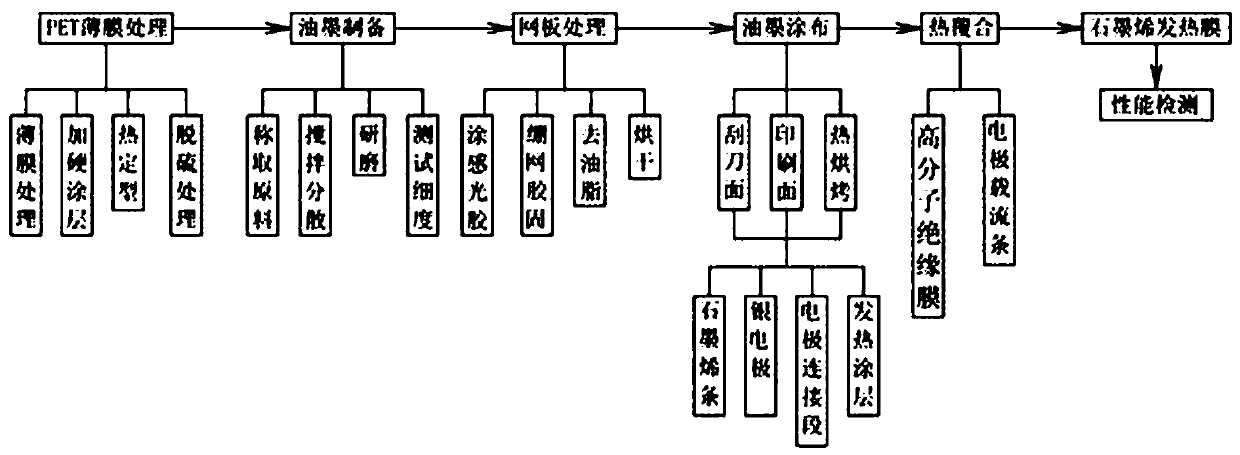

[0037] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described below in conjunction with the production process flow chart of graphene heating film and the structural diagram of graphene heating film.

[0038] Such as Figure 1-3 Shown, the preparation method of graphene heating film is characterized in that comprising the steps:

[0039] S1. Processing of PET film:

[0040] The PET film 1 used in the present invention is a modified PET film, that is, a general-purpose PET substrate is added with a toughening agent to make it have better toughness and bending strength. At the same time, corona treatment is first performed on both sides of the modified PET film 1, so that the Diane value on both sides reaches 54-56; then the surface is hard-coated; and then heat-setting and desulfurization are carried out at 180°C for 30 minutes Treatment; the treated PET film ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com