A method for preparing heterogeneous materials by plasma cladding

A technology of plasma cladding and plasma gas, which is applied in metal material coating technology, additive manufacturing, additive processing, etc., can solve the problem of difficulty in guaranteeing the bonding strength of the composite interface, high precision requirements for equipment and molds, and difficulty in controlling interface oxidation, etc. problems, to avoid the incorporation of impurities and interface oxidation, to meet the needs of strengthening and toughening, and to achieve various cladding styles and shapes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

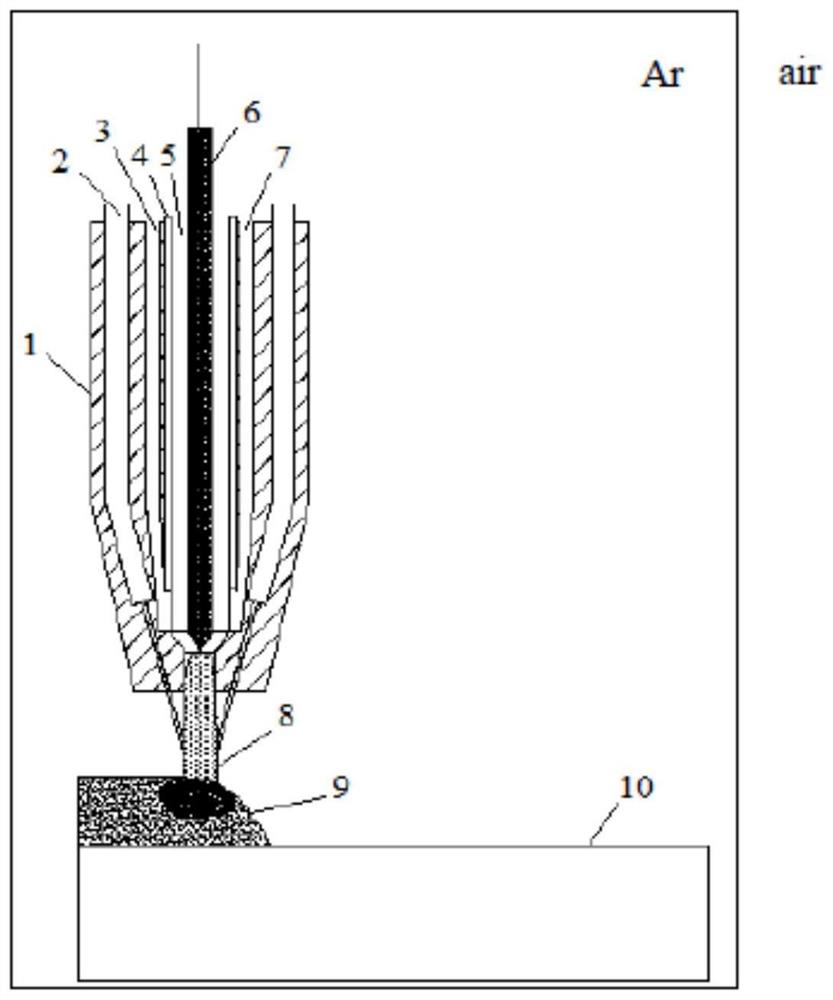

[0045] Example 1: Plasma cladding Al / 7075 aluminum alloy strip heterostructure

[0046] (1) Pretreatment: including substrate pretreatment and cladding powder pretreatment.

[0047] Substrate pretreatment: cutting the high-strength 7075 aluminum alloy into strips with a size of 100mm×20mm×20mm. Then carry out sandblasting (black corundum sand) treatment on 7075 aluminum alloy to remove rust. During sandblasting, the gun is 6cm away from the sample surface, and the sandblasting angle is 80°. After sandblasting, it is blown with cold compressed air; Ultrasonic cleaning for 30 minutes in order to remove oil, dry and set aside.

[0048] Cladding powder pretreatment: sieve the high-toughness Al and high-strength 7075 aluminum alloy powder for the second time, so that the particle size distribution is 80-100 mesh, and the powder shape is spherical or spherical; Keep drying at 150°C for 4 hours in a vacuum drying oven, and it can be turned during the drying process.

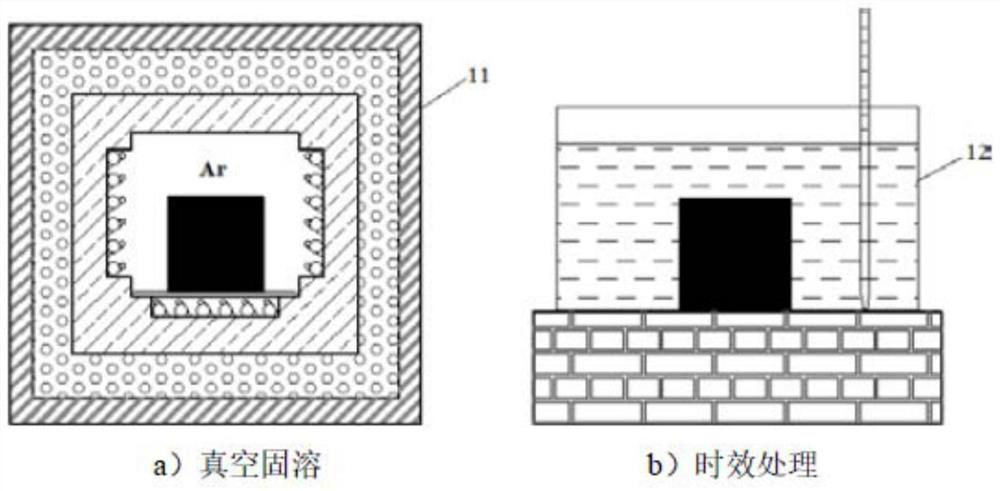

[0049] (2) B...

example 2

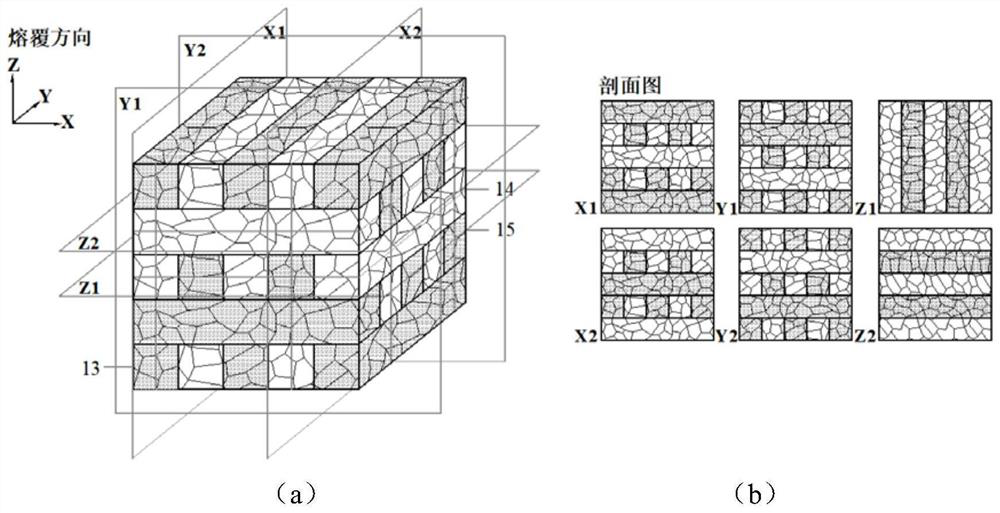

[0055] Example 2: Plasma cladding Al / 7075 aluminum alloy bulk heterostructure

[0056] (1) Pretreatment: including substrate pretreatment and cladding powder pretreatment.

[0057] Substrate pretreatment: cutting the high-strength 7075 aluminum alloy into blocks with a size of 60mm×40mm×30mm. Then carry out sandblasting (black corundum sand) treatment on 7075 aluminum alloy to remove rust. During sandblasting, the gun is 6cm away from the sample surface, and the sandblasting angle is 80°. After sandblasting, it is blown with cold compressed air; Ultrasonic cleaning for 30 minutes in order to remove oil, dry and set aside.

[0058] Cladding powder pretreatment: sieve the high-toughness Al and high-strength 7075 aluminum alloy powder for the second time, so that the particle size distribution is 80-100 mesh, and the powder shape is spherical or spherical; Keep drying at 150°C for 4 hours in a vacuum drying oven, and it can be turned during the drying process.

[0059] (2) Bot...

example 3

[0065] Example 3: Concave-convex heterogeneous structure of plasma cladding Al / 7075 aluminum alloy

[0066](1) Pretreatment: including substrate pretreatment and cladding powder pretreatment.

[0067] Substrate pretreatment: Cut the high-strength 7075 aluminum alloy into a concave-convex shape with a lower plane size of 45mm×30mm×10mm and three upper convex sizes of 45mm×10mm×10mm (size 1) distributed on the left, middle and right sides. Then carry out sandblasting (black corundum sand) treatment on 7075 aluminum alloy to remove rust. During sandblasting, the gun is 6cm away from the sample surface, and the sandblasting angle is 80°. After sandblasting, it is blown with cold compressed air; Ultrasonic cleaning for 30 minutes in order to remove oil, dry and set aside.

[0068] Cladding powder pretreatment: sieve the high-toughness Al and high-strength 7075 aluminum alloy powder for the second time, so that the particle size distribution is 80-100 mesh, and the powder shape is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com