Ultraviolet curing silk-screen printing metal ink and preparation method thereof

A technology of screen printing and metal ink, which is applied in the field of ultraviolet curing screen printing metal ink and its preparation, can solve the problems affecting the storage stability of ink and the production and use of printing factories, and achieve excellent storage stability and short preparation time , good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to describe the content of the present invention more clearly and completely, the concept of the present invention will be described below in conjunction with specific embodiments.

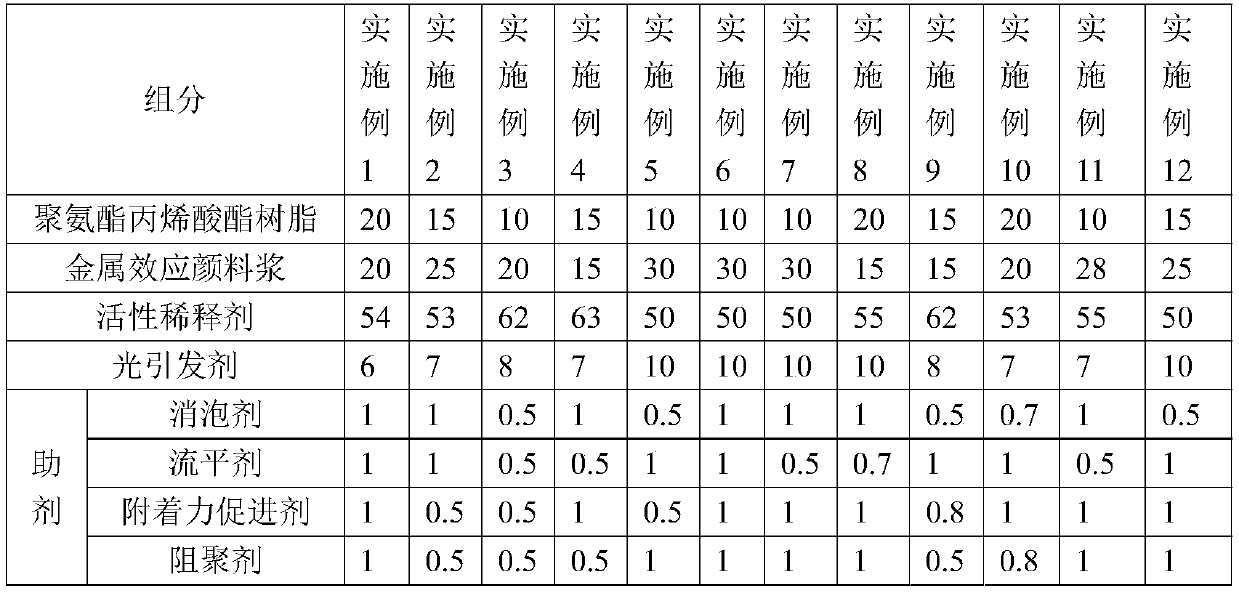

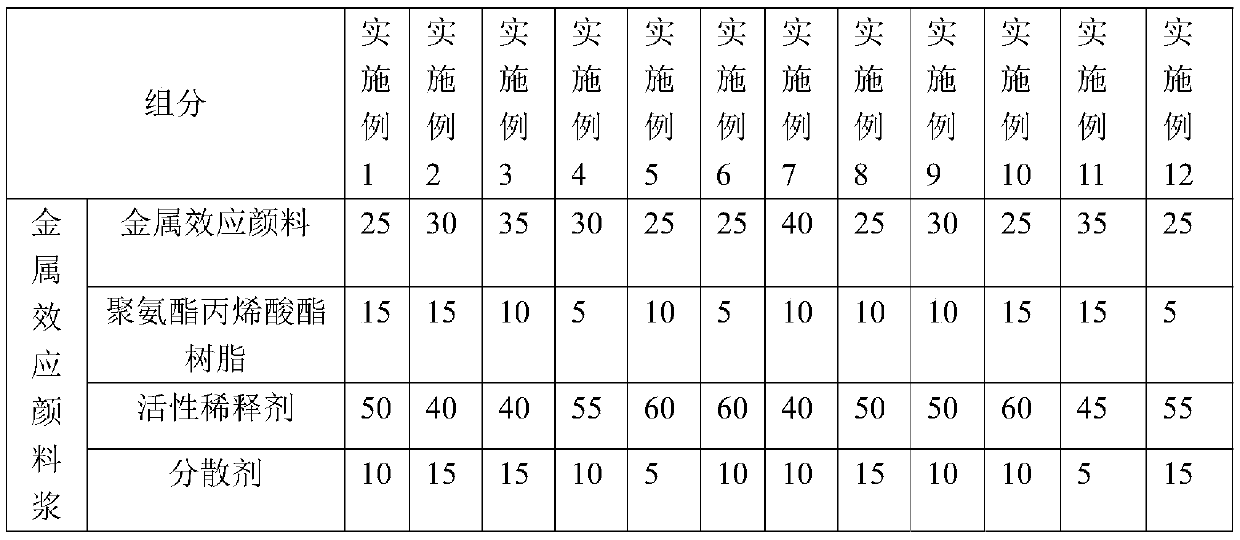

[0035] According to the proportioning relationship in Table 1 to Table 9, add polyurethane acrylate resin, active diluent and dispersant to the reaction kettle in proportion, and then stir and disperse with a disc stirring paddle. The dispersion time is 20 to 30 minutes. The dispersion system The temperature is controlled between 20°C and 40°C.

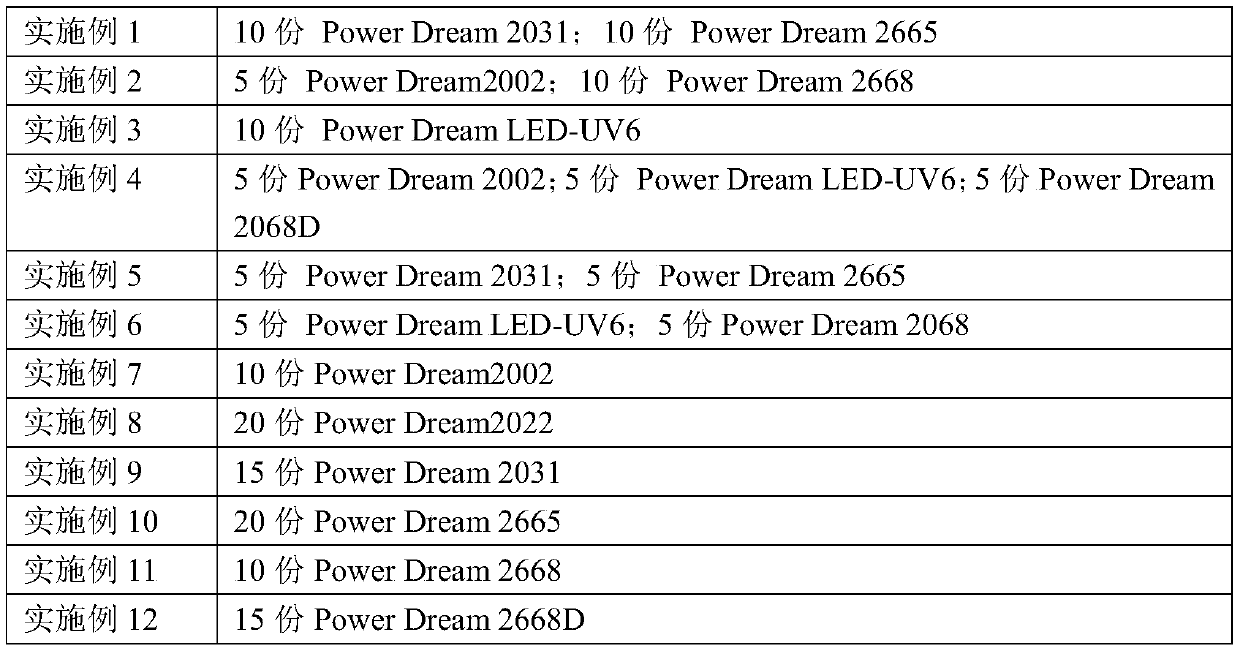

[0036]Add active diluent, photoinitiator, defoamer, leveling agent, adhesion promoter and polymerization inhibitor in proportion, and then stir and disperse with disc stirring paddle. , and mix the mixture evenly to obtain the finished UV-curable screen printing metal ink, wherein the dispersion time is 30-60 minutes, and the temperature of the dispersion system is controlled at 20°C-40°C.

[0037] Among them, the polyurethane acrylate re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com