Melt-blown polypropylene with ultra-long antibacterial effect and preparation method and application thereof

A polypropylene and organic antibacterial agent technology, applied in the field of polymer materials, can solve problems such as poor thermal stability of organic antibacterial agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

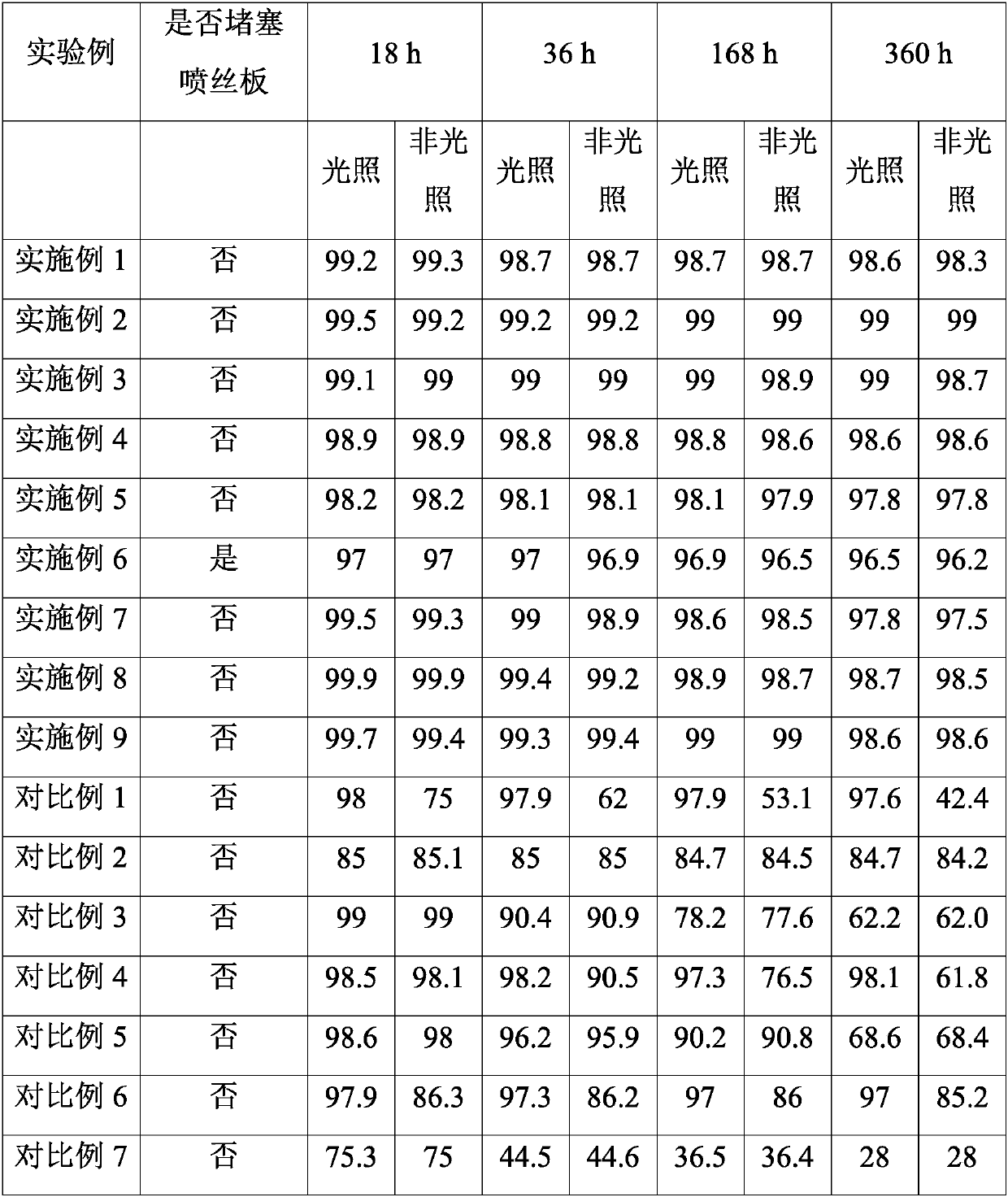

Examples

Embodiment 1

[0090] S1, modification of inorganic nano antibacterial agent:

[0091] 1) Put the silane coupling agent KH550 into a beaker filled with absolute ethanol, stir and dilute;

[0092] 2) Add nano-titanium dioxide and nano-alumina (1:1) into (1) diluent, and stir thoroughly;

[0093] 3) The liquid prepared in 2) was reacted at 80° C. for 30 minutes, and the precipitate was collected after centrifugation, dried and ground for later use.

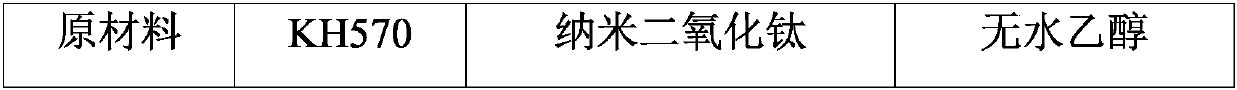

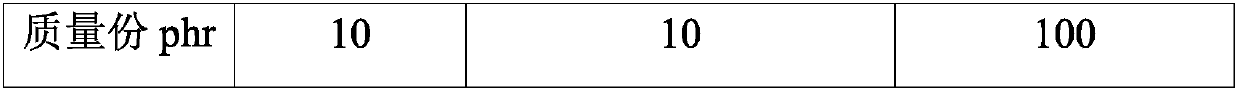

[0094] Table 1: Raw material usage table in S1

[0095] raw material KH550 Nano titanium dioxide + nano alumina Absolute ethanol parts by mass phr 10 10 100

[0096] S2, preparation of organic antibacterial agent masterbatch

[0097] Mix 100 parts by weight of melt-blown grade polypropylene, 0.5% by weight of zinc pyrithione, 0.1% by weight of discoloration inhibitor basic zinc carbonate, and 0.1% by weight of antioxidant 1010 in a mixer, Adding into twin-screws for melt blending and extruding, cooling and pelletizin...

Embodiment 2

[0103] Repeat the process of embodiment 1, difference is: the parts by weight of zinc pyrithione is 1% in the organic antibacterial agent masterbatch.

Embodiment 3

[0105] Repeat the process of embodiment 1, difference is: the parts by weight of zinc pyrithione is 3% in the organic antibacterial agent masterbatch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com