Fuel cell compressor test equipment, test method, coolant flow rate determination method and application

A kind of test equipment, fuel cell technology, applied in mechanical equipment, using thermal variable to measure fluid speed, pump test, etc., to achieve the effect of reliable test, high degree of automation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

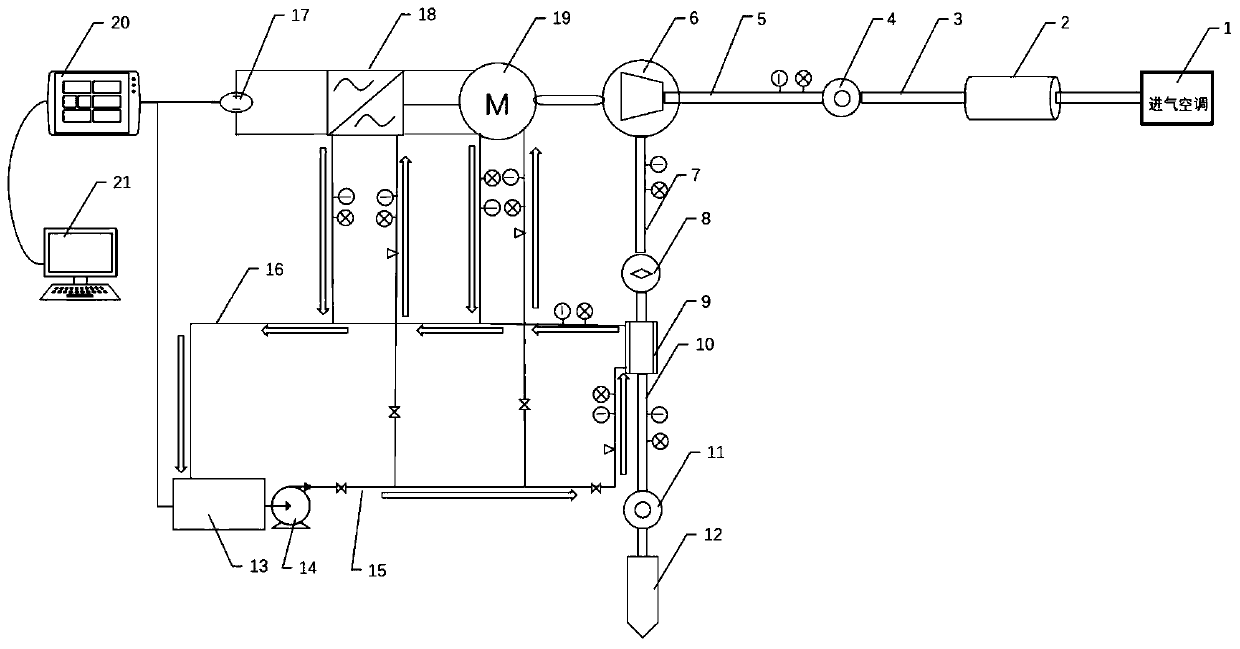

[0081] Example 1: Such as figure 1 As shown, a fuel cell compressor test bench includes an intake and exhaust system, a cooling system, a control system, a power supply system and a base.

[0082] Including computer software, PLC, sensors, actuators, and controllers in an integrated system, including air intake and exhaust systems, cooling systems, control systems, power supply systems, and bases, etc., characterized by: most of the test benches are installed in On the base, the air intake system includes an air intake pipe, an air flow meter, an air filter, a hot film flow meter, a pressure sensor and a temperature sensor. The exhaust system includes an exhaust pipe, a vortex flowmeter, an intercooler, a throttle, a hot film flowmeter, a silencer, a pressure sensor and a temperature sensor. The cooling system includes a cooling unit, a cooling pipe, and a liquid flow meter. The power supply system uses a power distribution cabinet to supply power to a high-speed motor after f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com