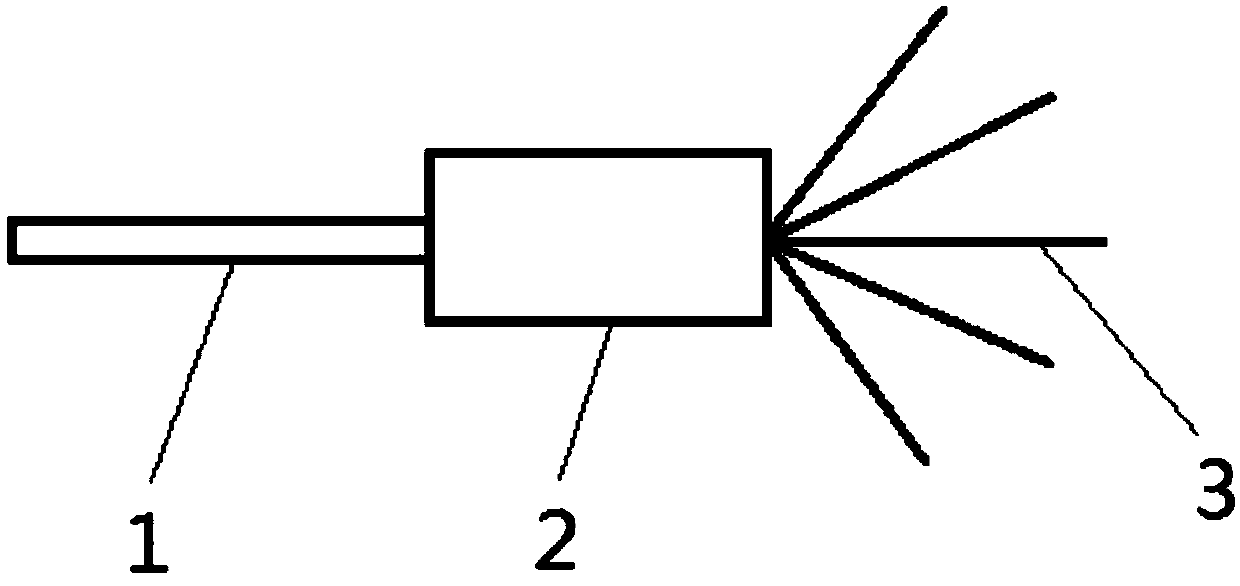

Fullerene negative ion release head, preparation method thereof and negative ion generation electrode

A technology of fullerenes and negative ions, applied in fullerenes, corona discharge devices, circuits, etc., can solve the problems of insoluble fullerenes, limitations, etc., and achieve shortened process time, longer service life, and long migration distance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

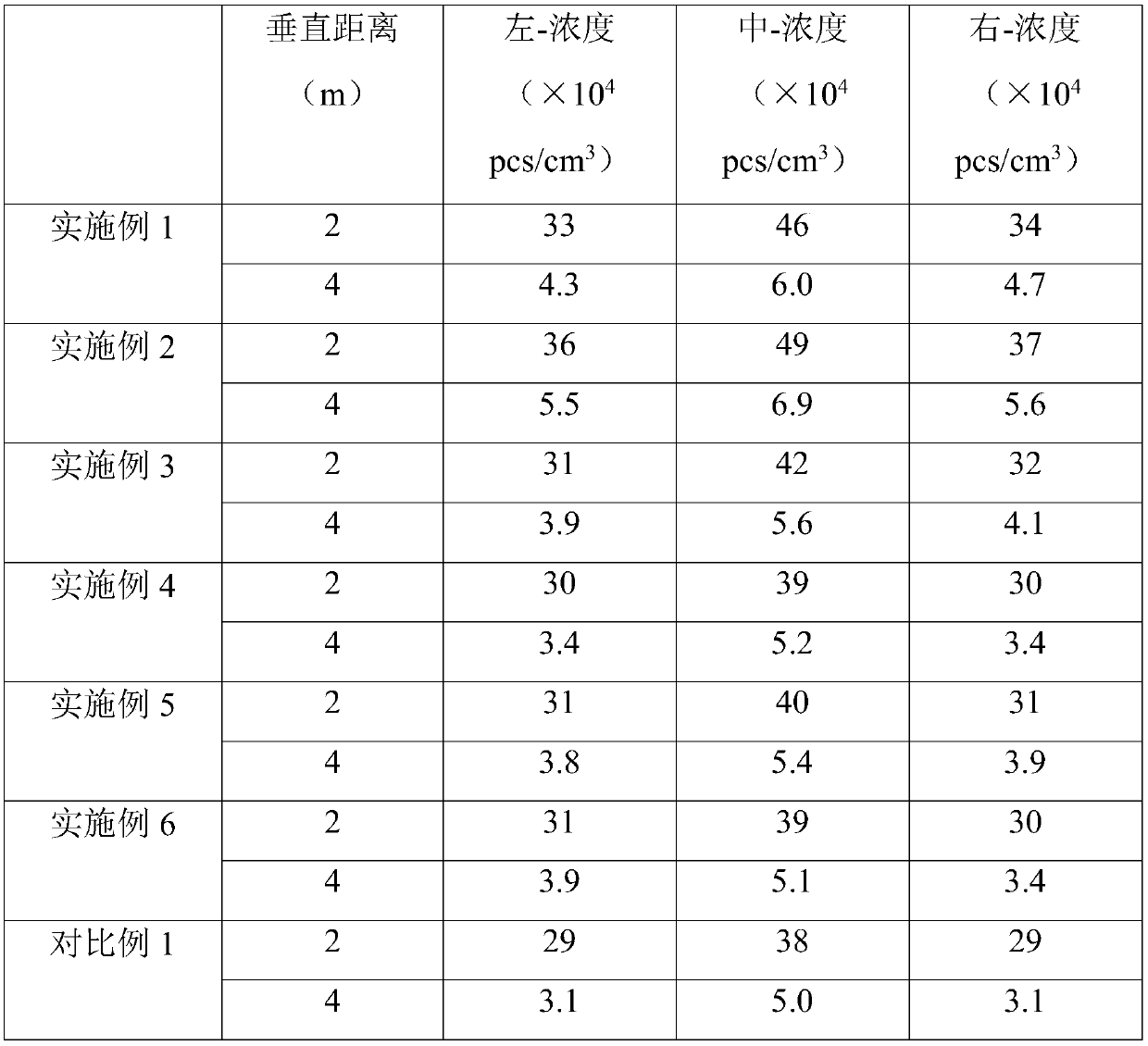

[0053]The method for preparing a fullerene anion releasing head provided by the present invention improves the solubility of fullerene in water through surface modification, significantly shortens the process time for preparing a fullerene anion releasing head by using a fullerene aqueous solution, and improves the anion The production efficiency of the release head reduces the cost. Moreover, dissolving into water, which is finally used to dissolve fullerenes, is a safe, environmentally friendly, and pollutant-free preparation method.

[0054] At the same time, the surface modification has no adverse effect on the performance of the fullerene anion release head, and the prepared fullerene anion release head can still produce ecological grade small particle size negative oxygen with small particle size, high activity, and long migration distance. ions, and the negative ions are of high purity, and there are almost no by-products such as ozone and nitrogen oxides. In addition,...

Embodiment 1

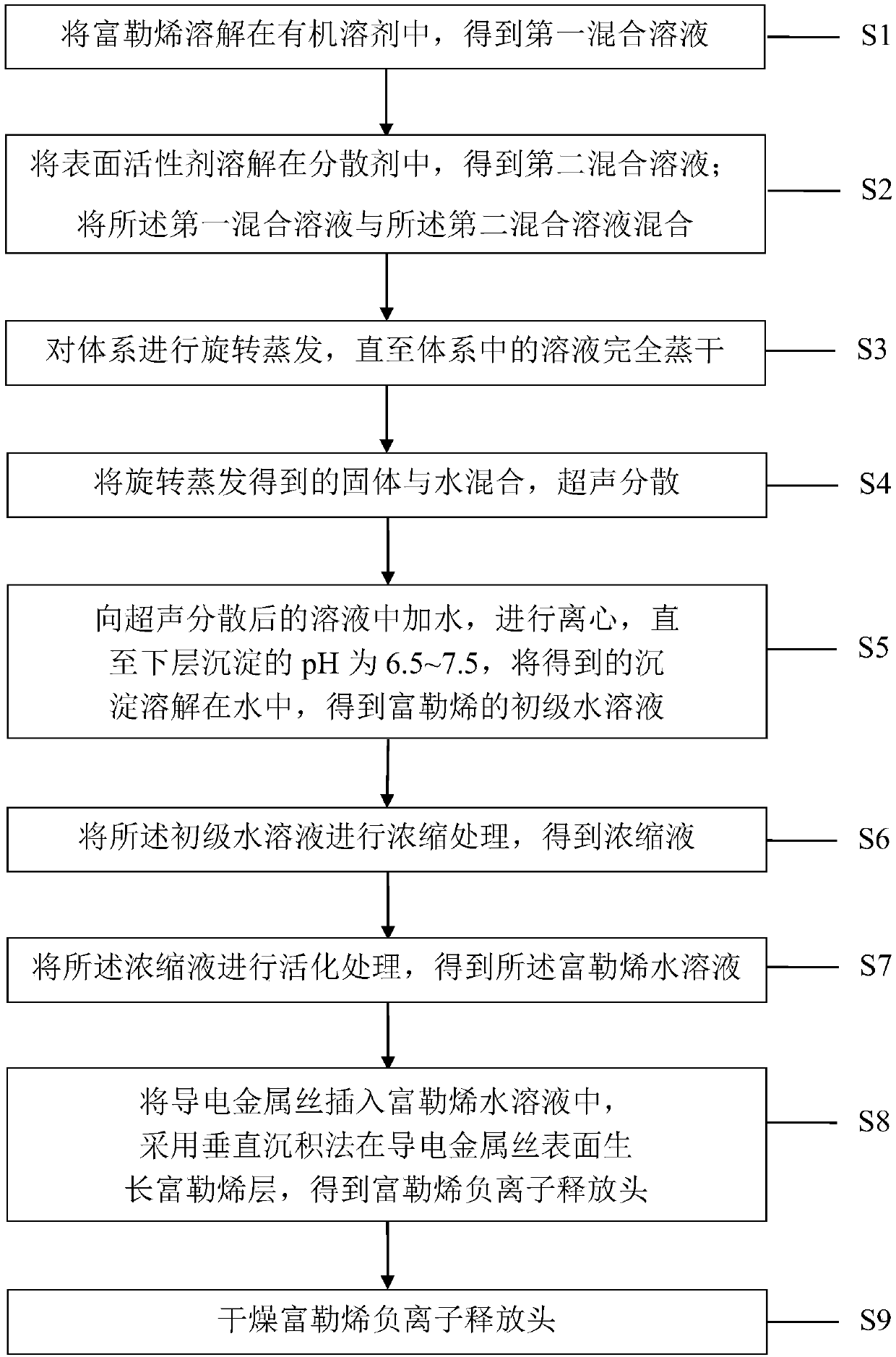

[0089] like figure 2 Shown, the method for preparing fullerene anion releasing head of the present embodiment comprises:

[0090] S1: Add toluene to the container containing fullerene, control the mass ratio of fullerene to toluene to be 1:1, and disperse ultrasonically at a frequency of 100 times / min until no fullerene is attached to the inner wall of the container And the solution in the container is not stratified, and the first mixed solution is obtained;

[0091] S2: Mix polyvinylpyrrolidone and chloroform to obtain a second mixed solution, control the mass fraction of polyvinylpyrrolidone in the second mixed solution to be 15%, add the first mixed solution obtained in step S1 into the second mixed solution, control the The mass ratio of leene to polyvinylpyrrolidone is 1:100, and the magnetic stirring makes the two fully mixed;

[0092] S3: Rotate the solution obtained in step S2 at 60°C with a rotation speed of 100r / min until the solution in the system is completely ...

Embodiment 2

[0100] like figure 2 Shown, the method for preparing fullerene anion releasing head of the present embodiment comprises:

[0101] S1: Add toluene to the container containing fullerene, control the mass ratio of fullerene to toluene to 0.5:1, and disperse ultrasonically at a frequency of 130 times / min until no fullerene is attached to the inner wall of the container And the solution in the container is not stratified, and the first mixed solution is obtained;

[0102] S2: Mix polyvinylpyrrolidone and chloroform to obtain a second mixed solution, control the mass fraction of polyvinylpyrrolidone in the second mixed solution to be 10%, add the first mixed solution obtained in step S1 into the second mixed solution, control the The mass ratio of leene to polyvinylpyrrolidone is 1:125, and the magnetic stirring makes the two fully mix;

[0103] S3: Rotate the solution obtained in step S2 at 70°C with a rotation speed of 150r / min until the solution in the system is completely eva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com