Preparation method and application of carbon-iron composite material with porous structure

A porous structure, composite material technology, applied in chemical instruments and methods, alkali metal compounds, water treatment of special compounds, etc., can solve the problem of difficult separation of carbon materials, achieve simple and convenient experimental steps, good adsorption performance, and improve adsorption efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

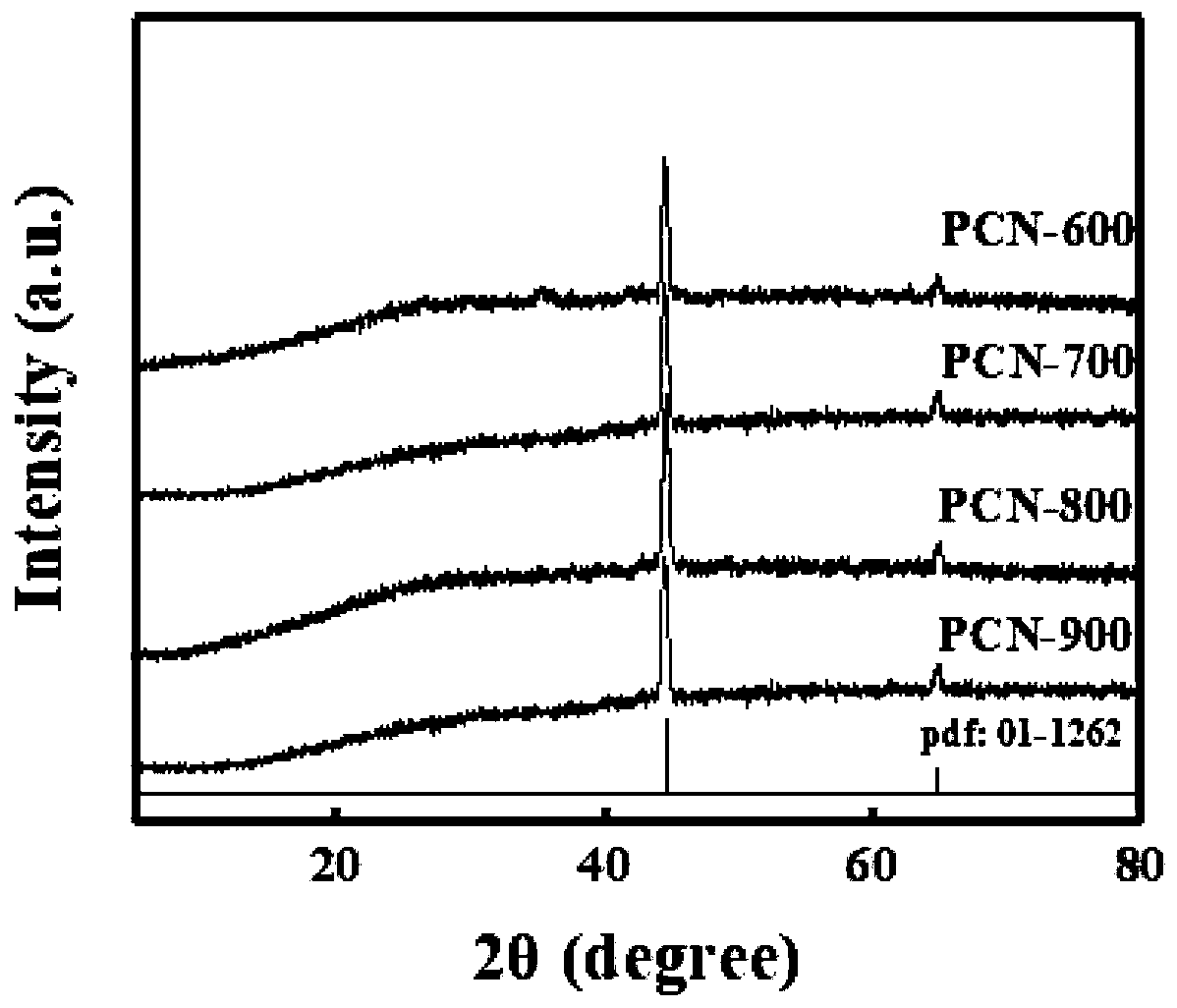

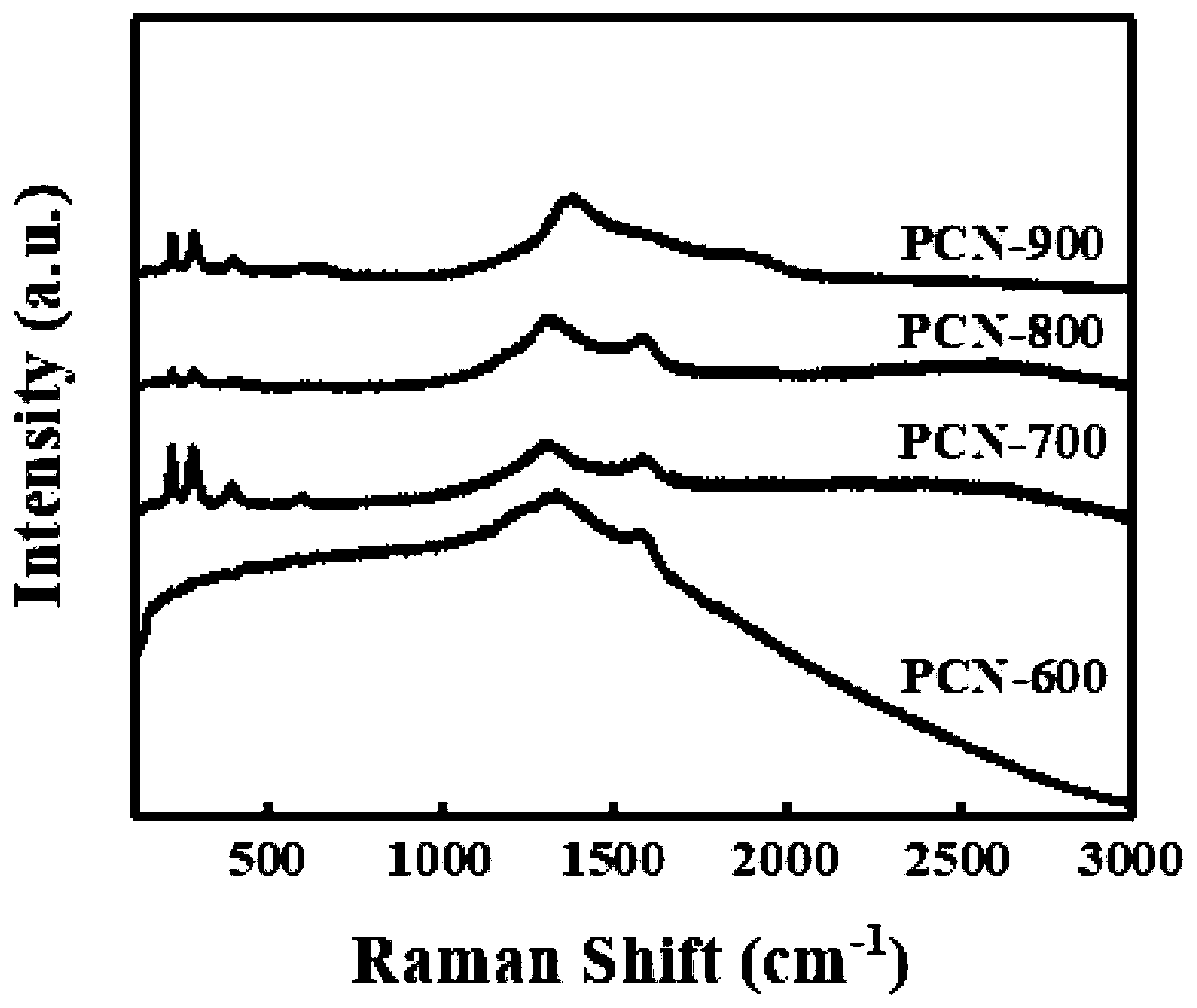

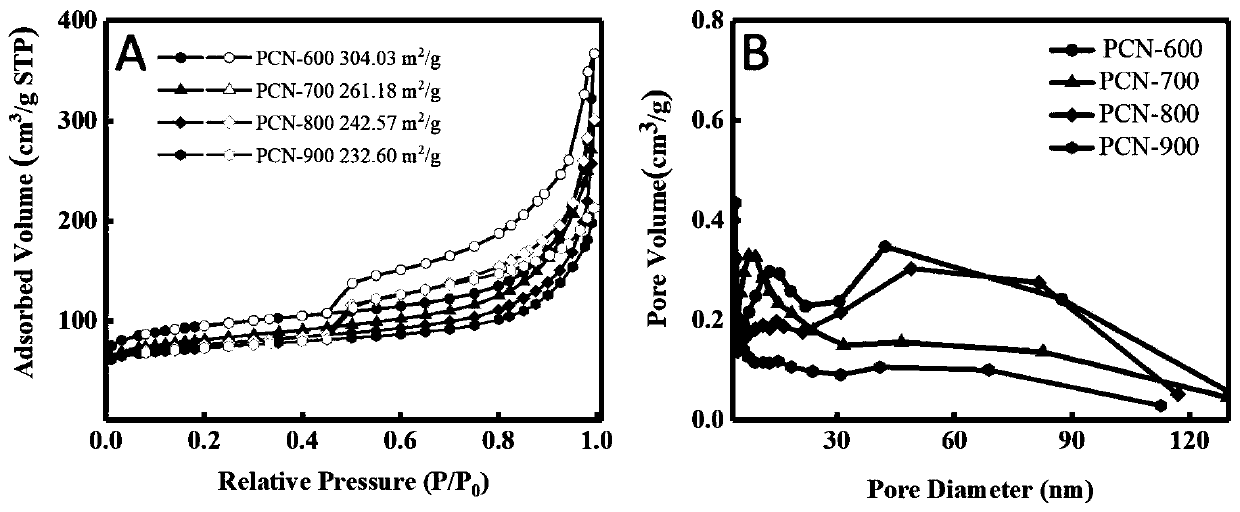

[0041] Preparation of PCN-600:

[0042] Put 500mg of MIL-101(Fe) orange powder into a porcelain boat, calcinate in a tube furnace under a nitrogen atmosphere, heat at 3°C for 1h to 600°C per minute, N 2 Cool to room temperature under atmosphere. The black powder was washed with water, then magnetically separated, and dried at 70°C to obtain the product.

Embodiment 2

[0044] Preparation of PCN-700:

[0045] Put 500mg of MIL-101(Fe) orange powder into a porcelain boat, calcinate in a tube furnace under a nitrogen atmosphere, heat at 3°C for 1h to 700°C per minute, N 2 Cool to room temperature under atmosphere. The black powder was washed with water, then magnetically separated, and dried at 70°C to obtain the product.

Embodiment 3

[0047] Preparation of PCN-800:

[0048] Put 500mg of MIL-101(Fe) orange powder into a porcelain boat, calcinate in a tube furnace under a nitrogen atmosphere, heat at 3°C for 1h to 800°C per minute, N 2 Cool to room temperature under atmosphere. The black powder was washed with water, then magnetically separated, and dried at 70°C to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com