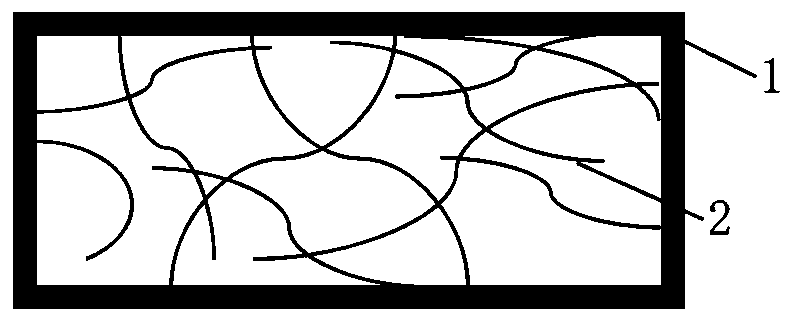

Amorphous cobalt sulfide nanowire and preparation method thereof

A cobalt sulfide nano and amorphous technology, applied in cobalt sulfide, chemical instruments and methods, nano carbon and other directions, to achieve the effects of controllable preparation process, good application prospects and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

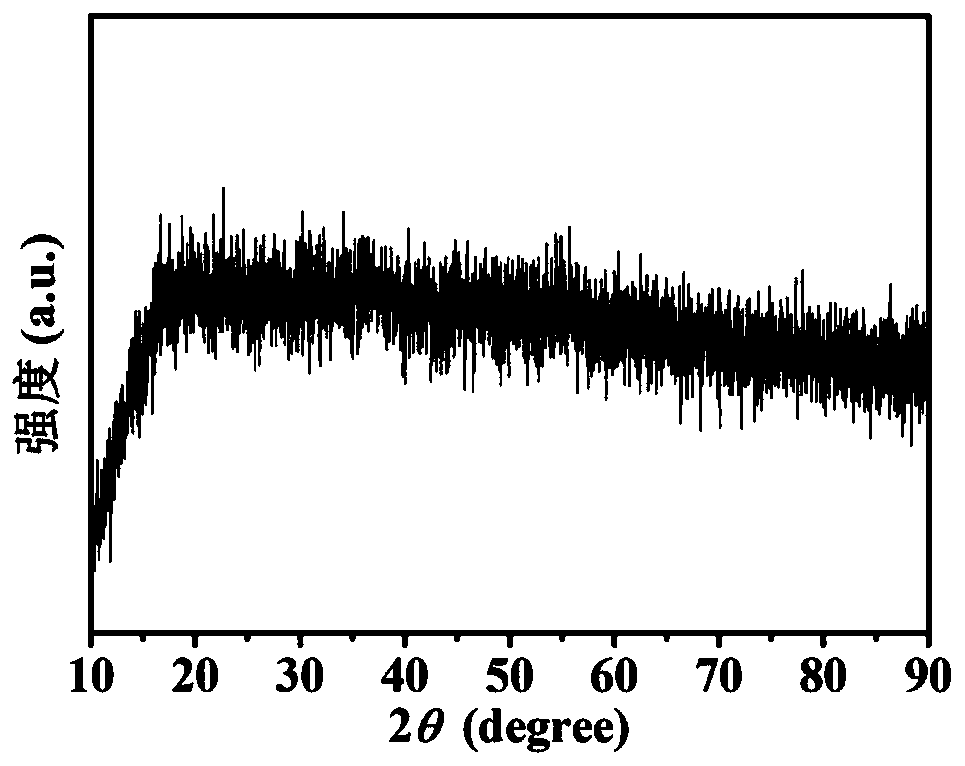

Examples

Embodiment 1

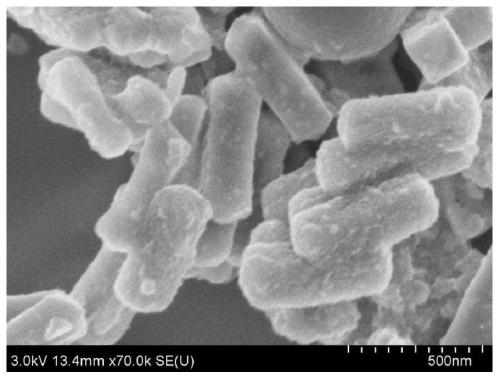

[0033] In a typical synthesis, 0.1 mmol of cobalt acetate tetrahydrate [Co(CH 3 COO) 2 4H 2 O] and 10mmol polyvinylpyrrolidone (K-30) were added to absolute ethanol, and after complete dissolution, a mixed solution was formed.

[0034] Then the above mixed solution was ultrasonically stirred for 30 minutes and then transferred to a polytetrafluoroethylene reactor for hydrothermal treatment. The hydrothermal temperature was kept at 90 ° C and the hydrothermal time was 2 hours. Then the powder generated by the reaction was collected by centrifugation and washed with absolute ethanol Washing, drying in vacuum for at least 12 hours to obtain nano-cobalt rod-shaped precursors, the particle diameter of these nano-cobalt rod-shaped precursors is between 100nm and 1000nm.

[0035] Then above-mentioned nano-cobalt rod-shaped precursor and L-cysteine and glucose powder are added respectively in dehydrated alcohol, after completely dissolving, be made into mixed solution, wherein, af...

Embodiment 2

[0038] In a typical synthesis, 0.1 mmol of cobalt acetate tetrahydrate [Co(CH 3 COO) 2 4H 2 O] and 20mmol polyvinylpyrrolidone (K-30) were added to absolute ethanol, and after complete dissolution, a mixed solution was formed.

[0039] Then the above mixed solution was ultrasonically stirred for 30 minutes and then transferred to a polytetrafluoroethylene reactor for hydrothermal treatment. The hydrothermal temperature was kept at 100 ° C and the hydrothermal time was 4 hours. Then the powder generated by the reaction was collected by centrifugation and washed with absolute ethanol. Washing, drying in vacuum for at least 12 hours to obtain nano-cobalt rod-shaped precursors, the particle diameter of these nano-cobalt rod-shaped precursors is between 100nm and 1000nm.

[0040] Then above-mentioned nano-cobalt rod-shaped precursor and L-cysteine and glucose powder are added respectively in dehydrated alcohol, after completely dissolving, be made into mixed solution, wherein, af...

Embodiment 3

[0043] In a typical synthesis, 0.1 mmol of cobalt acetate tetrahydrate [Co(CH 3 COO) 2 4H 2 O] and 20mmol polyvinylpyrrolidone (K-30) were added to absolute ethanol, and after complete dissolution, a mixed solution was formed.

[0044] Then the above mixed solution was ultrasonically stirred for 30 minutes and then transferred to a polytetrafluoroethylene reactor for hydrothermal treatment. The hydrothermal temperature was kept at 120 ° C and the hydrothermal time was 3 hours. Then the powder generated by the reaction was collected by centrifugation and washed with absolute ethanol Washing, drying in vacuum for at least 12 hours to obtain nano-cobalt rod-shaped precursors, the particle diameter of these nano-cobalt rod-shaped precursors is between 100nm and 1000nm.

[0045] Then above-mentioned nano-cobalt rod-shaped precursor and L-cysteine and glucose powder are added respectively in dehydrated alcohol, after completely dissolving, be made into mixed solution, wherein, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com