Solid carbon source suitable for high-concentration nitrate nitrogen sewage treatment and preparation method thereof

A solid carbon source, sewage treatment technology, applied in water/sludge/sewage treatment, special compound water treatment, anaerobic digestion treatment, etc. , lignin is not easy to use and other problems, to achieve the effect of improving bioavailability, improving biodegradability, and improving degradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A method for preparing a solid carbon source suitable for high-concentration nitrate nitrogen sewage treatment, comprising the following steps:

[0037] Step 1. Mix PBS, bio-fermented bamboo powder, starch, water and silane coupling agent in a high-speed mixer according to a predetermined ratio;

[0038] Step 2. Add the mixed material into the twin-screw extruder, adjust the temperature to 110-130°C, banbury, melt, blend, and stir evenly; the banbury temperature is 110-130°C, and the time is 5-15 min.

[0039] Step 3, the blend is extruded through a twin-screw extruder, and the extruded product is water-cooled, crushed and granulated by a crusher, and dried.

[0040] The raw materials and reagents used in the examples are commercially available, or can be prepared by known methods.

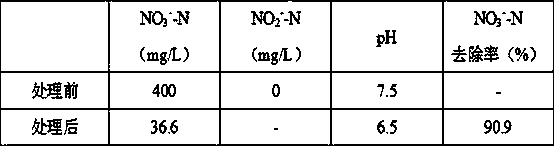

Embodiment 1

[0042] Put 30 parts of PBS, 45 parts of biologically fermented bamboo powder, 20 parts of starch, 2 parts of water and 3 parts of KH-570 into a twin-screw extruder and stir evenly. The banburying temperature is 120 °C and the time is 15 min. , Extrude, cool the blend to room temperature, crush and granulate with a crusher.

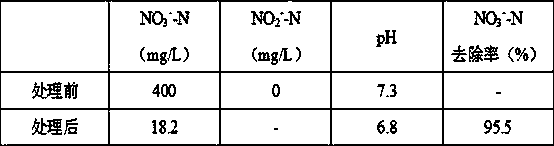

Embodiment 2

[0044] Put 50 parts of PBS, 35 parts of biologically fermented bamboo powder, 10 parts of starch, 2 parts of water and 3 parts of KH-550 into a twin-screw extruder and stir evenly. , Extrude, cool the blend to room temperature, crush and granulate with a crusher.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com