Novel process method for extracting hesperidin

A new process, the technology of hesperidin, is applied in the new process field of hesperidin extraction, which can solve the problems of large consumption of extraction solvent, slow progress of experimental reaction, no particularly strict control indicators, etc., and achieve the effect of reducing impurities and increasing content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

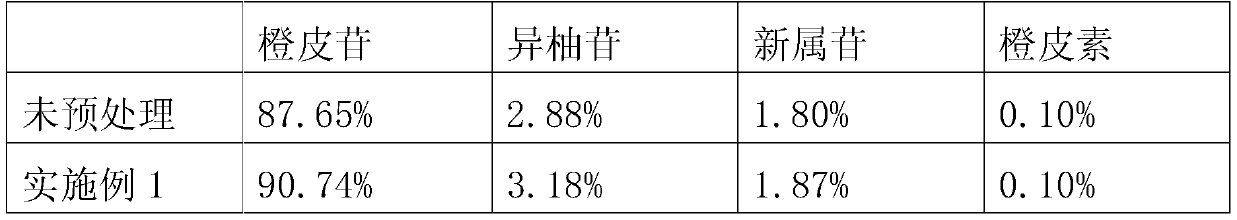

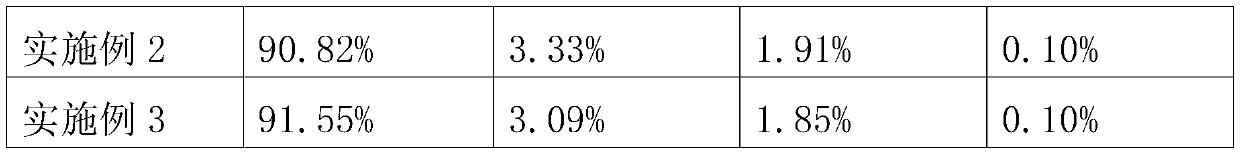

Examples

Embodiment 1

[0030] Step A. pulverize the Fructus Fructus Fructus Fructus Fructus Raw Material, and pulverize particle size 50 orders;

[0031] Step B. Pretreat the pulverized raw materials with sodium citrate solution for 4 hours, and control the concentration of sodium citrate solution at 3%;

[0032] Step C. After processing and filtering, add the filter residue to the alkaline extract, control the concentration at 1.5%, and extract for 5 hours;

[0033] Step D. Pass the alkaline extract first through coarse filtration, then perform fine filtration, and transfer the filtrate to a stirring tank;

[0034] Step E. During the stirring process of the extraction filtrate, slowly add hydrochloric acid to adjust the pH, the pH is controlled at 5.5, and wait for crystallization for 8 hours;

[0035] Step F. Pass the crystallization solution through the plate frame, and rinse the filter cake with purified water until it is colorless, then blow dry the filter cake, and transfer it to a drying ove...

Embodiment 2

[0037] Step A. Pulverize the Fructus Fructus Citrus Fructus raw material, and pulverize particle size 40 orders;

[0038] Step B. Pretreating the pulverized raw materials with sodium citrate solution for 5 hours, and controlling the concentration of the sodium citrate solution at 1%;

[0039] Step C. After processing and filtering, add the filter residue to the alkaline extract, control the concentration at 0.5%, and extract for 6 hours;

[0040] Step D. Pass the alkaline extract first through coarse filtration, then perform fine filtration, and transfer the filtrate to a stirring tank;

[0041] Step E. During stirring the extraction filtrate, slowly add hydrochloric acid to adjust the pH, the pH is controlled at 6.5, and wait for crystallization for 6 hours;

[0042] Step F. Pass the crystallization solution through the plate frame, and rinse the filter cake with purified water until it is colorless, blow dry the filter cake, and transfer it to a drying oven for drying at a ...

Embodiment 3

[0044] Step A. Pulverize the Fructus Fructus Citrus Fructus raw material, the pulverizing particle size is 60 orders;

[0045] Step B. Pretreat the pulverized raw materials with sodium citrate solution for 3 hours, and control the concentration of sodium citrate solution at 5%;

[0046] Step C. After processing and filtering, add the filter residue to the alkaline extract, control the concentration at 2.5%, and extract for 3 hours;

[0047] Step D. Pass the alkaline extract first through coarse filtration, then perform fine filtration, and transfer the filtrate to a stirring tank;

[0048] Step E. During the stirring process of the extraction filtrate, slowly add hydrochloric acid to adjust the pH, control the pH at 4.5, and wait for crystallization for 12 hours;

[0049] Step F. Pass the crystallization solution through the plate frame, and rinse the filter cake with purified water until it is colorless, then blow dry the filter cake, and transfer it to a drying oven for dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com