Monocrystalline silicon ingot and preparation method thereof, cast monocrystalline silicon wafer and preparation method for cast monocrystalline silicon wafer

A technology of monocrystalline silicon ingots and monocrystalline silicon wafers, which is applied in the field of silicon wafers to achieve the effect of reducing production costs, low production costs, and favorable application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

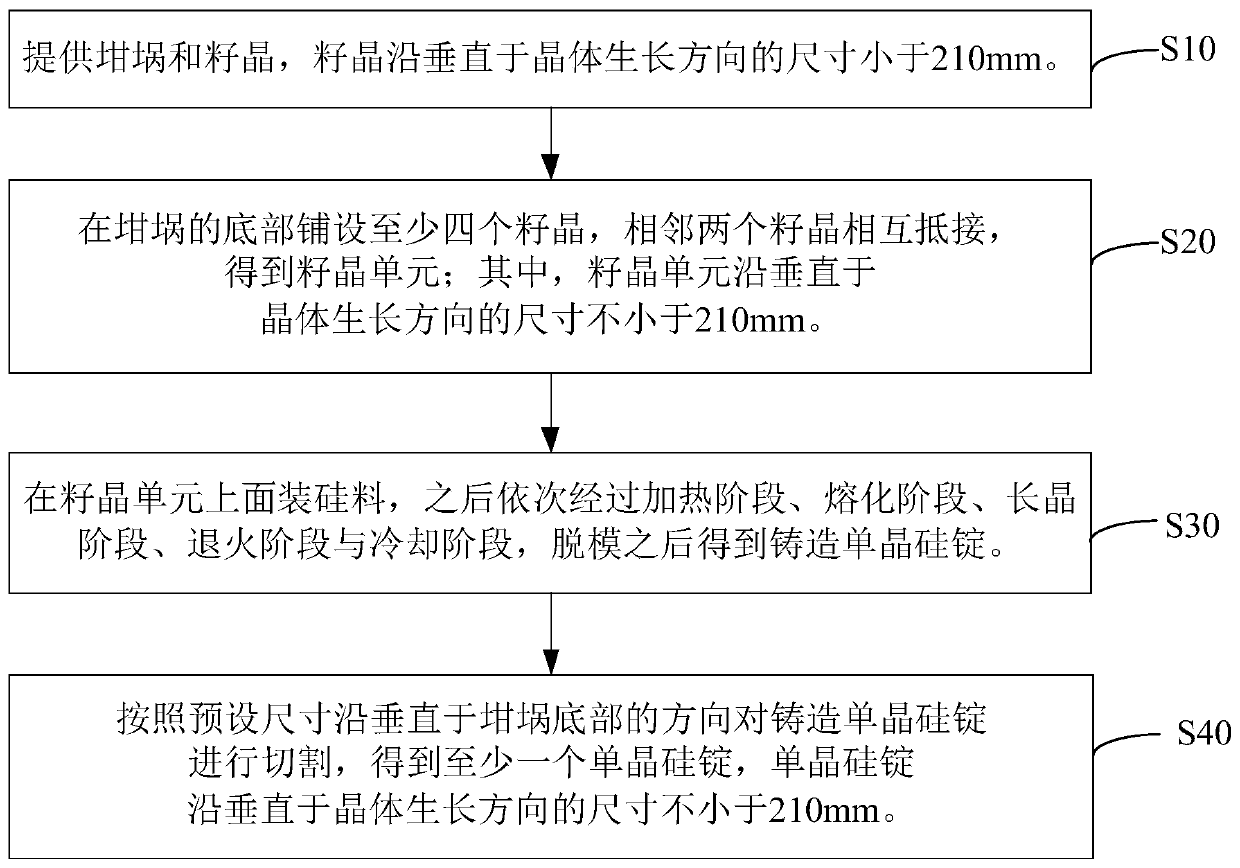

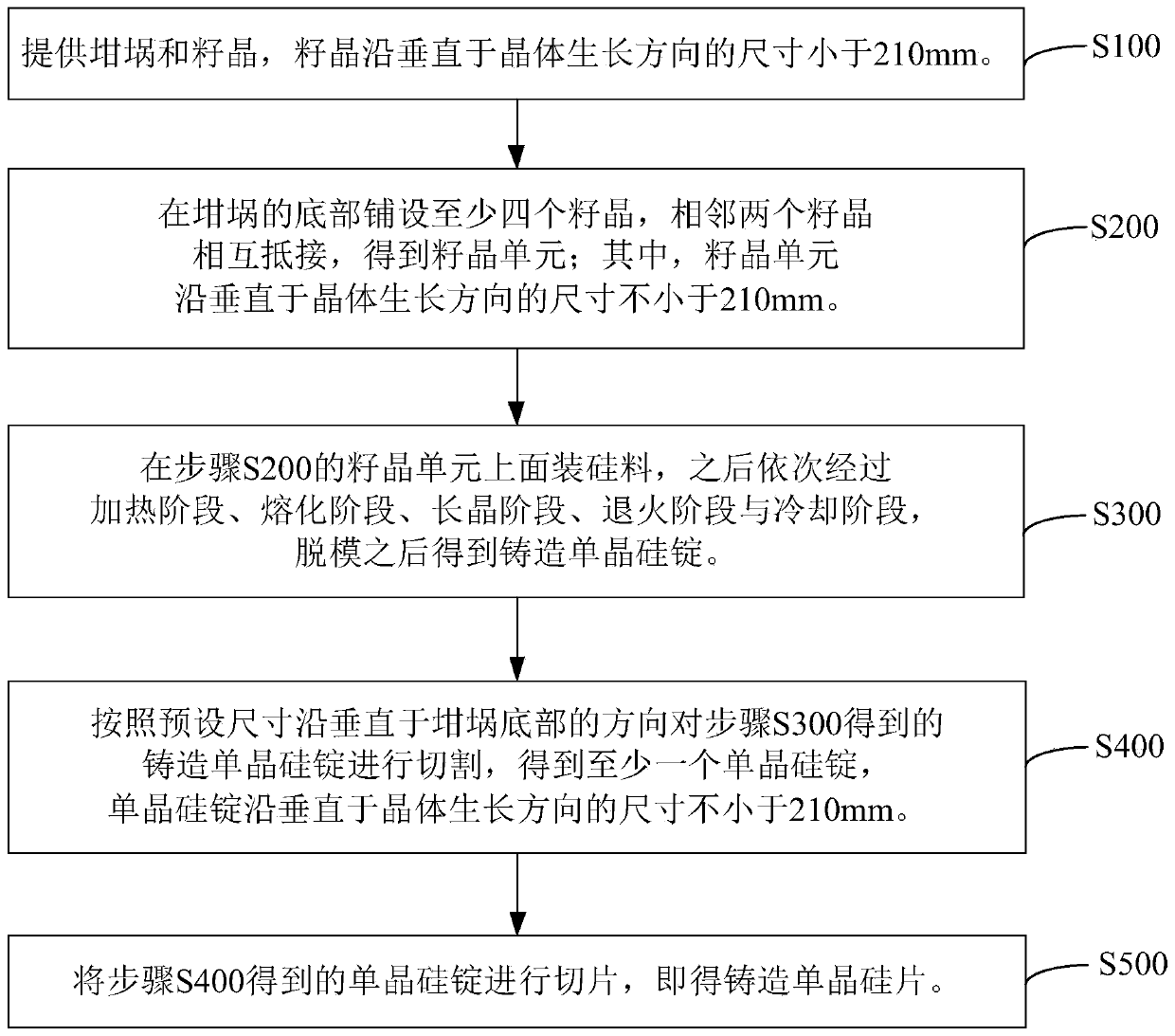

[0043] See figure 1 , The method for preparing a single crystal silicon ingot according to an embodiment of the present invention includes the following steps:

[0044] S10. Provide a crucible and a seed crystal, and the size of the seed crystal along the direction perpendicular to the crystal growth direction is less than 210mm.

[0045] Among them, the crucible is a crucible of polycrystalline silicon or single crystal silicon commonly used in the field, such as a quartz crucible.

[0046] Among them, the seed crystal is a small crystal with the same crystal orientation as the desired crystal, and is the seed for growing a single crystal, also called a seed crystal. The seed crystal is usually obtained by Czochralski. The size of the seed crystal along the direction perpendicular to the crystal growth direction is less than 210 mm means that the length of any side of the seed crystal along the direction perpendicular to the crystal growth direction is less than 210 mm. Wherein, th...

Embodiment 1

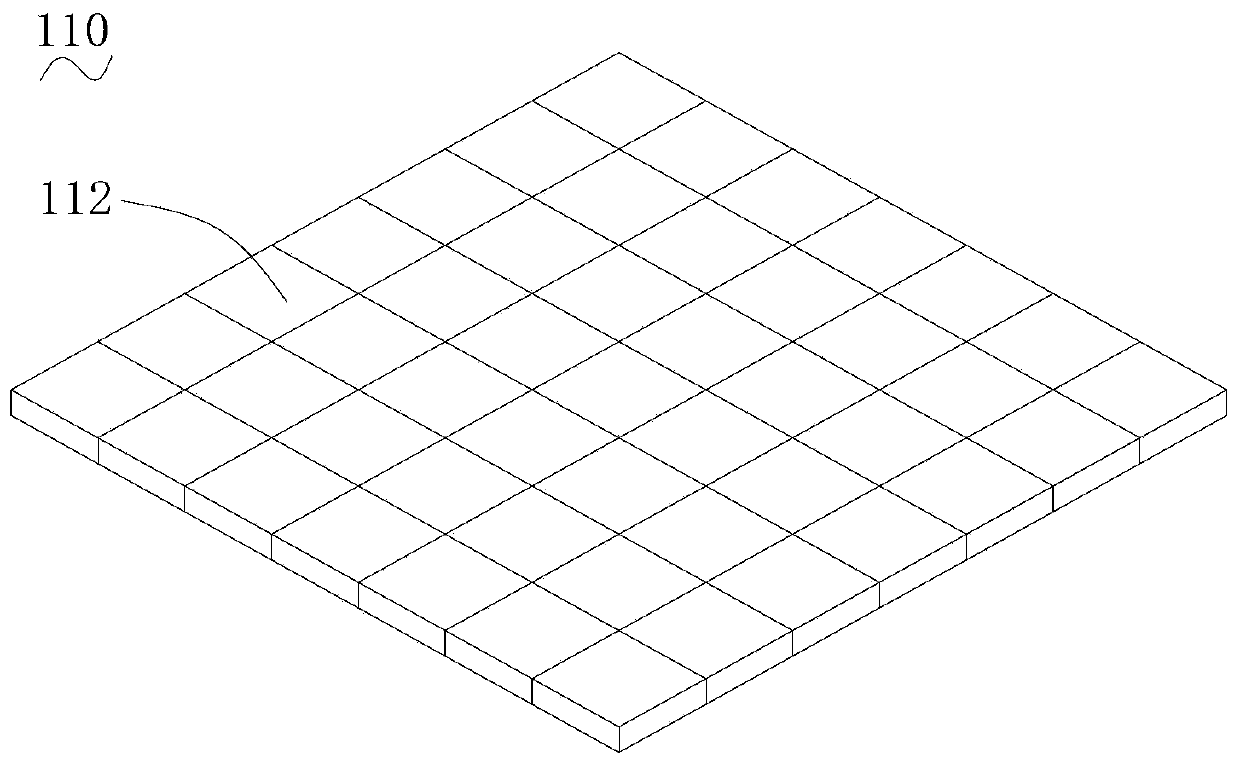

[0090] See image 3 The seed crystal unit 110 of an embodiment includes 49 square seed crystals 112 arranged in rows and columns, and adjacent seed crystals 112 are closely arranged. Wherein, the length and width of each seed crystal 112 are both 150 mm, and the number of seed crystals 112 in each row and column is 7 each.

[0091] The silicon material is loaded on the seed crystal unit 110, and then goes through the heating stage, the melting stage, the crystal growth stage, the annealing stage and the cooling stage. After demolding, a cast single crystal silicon ingot 120 is obtained. The weight of the cast single crystal silicon ingot 120 is approximately 1100Kg, such as Figure 4 Shown.

[0092] Figure 4 The middle dashed line is the cutting line. The cast single crystal silicon ingot 120 is cut along the cutting line to obtain 25 single crystal silicon ingots 122. Among them, the cutting lines include four transversely and four longitudinally, and the four transversely cutti...

Embodiment 2

[0096] See Image 6 The seed crystal unit 210 of Embodiment 2 includes 25 square seed crystals 212 arranged in rows and columns, and adjacent seed crystals 212 are closely arranged. The length and width of each seed crystal 212 are both 156 mm, and the number of seed crystals 212 in each row and column is 5.

[0097] The silicon material is loaded on the seed crystal unit 210, and then the heating phase, the melting phase, the crystal growth phase, the annealing phase and the cooling phase are successively passed through. After demolding, a cast single crystal silicon ingot 220 is obtained. The weight of the cast single crystal silicon ingot 220 is approximately 850Kg, such as Figure 7 Shown.

[0098] Figure 7 The middle dashed line is the cutting line. The cast single crystal silicon ingot 220 is cut along the cutting line to obtain 16 single crystal silicon ingots 222. Among them, the cutting lines include four horizontally and four longitudinally, and the four cutting lines i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap