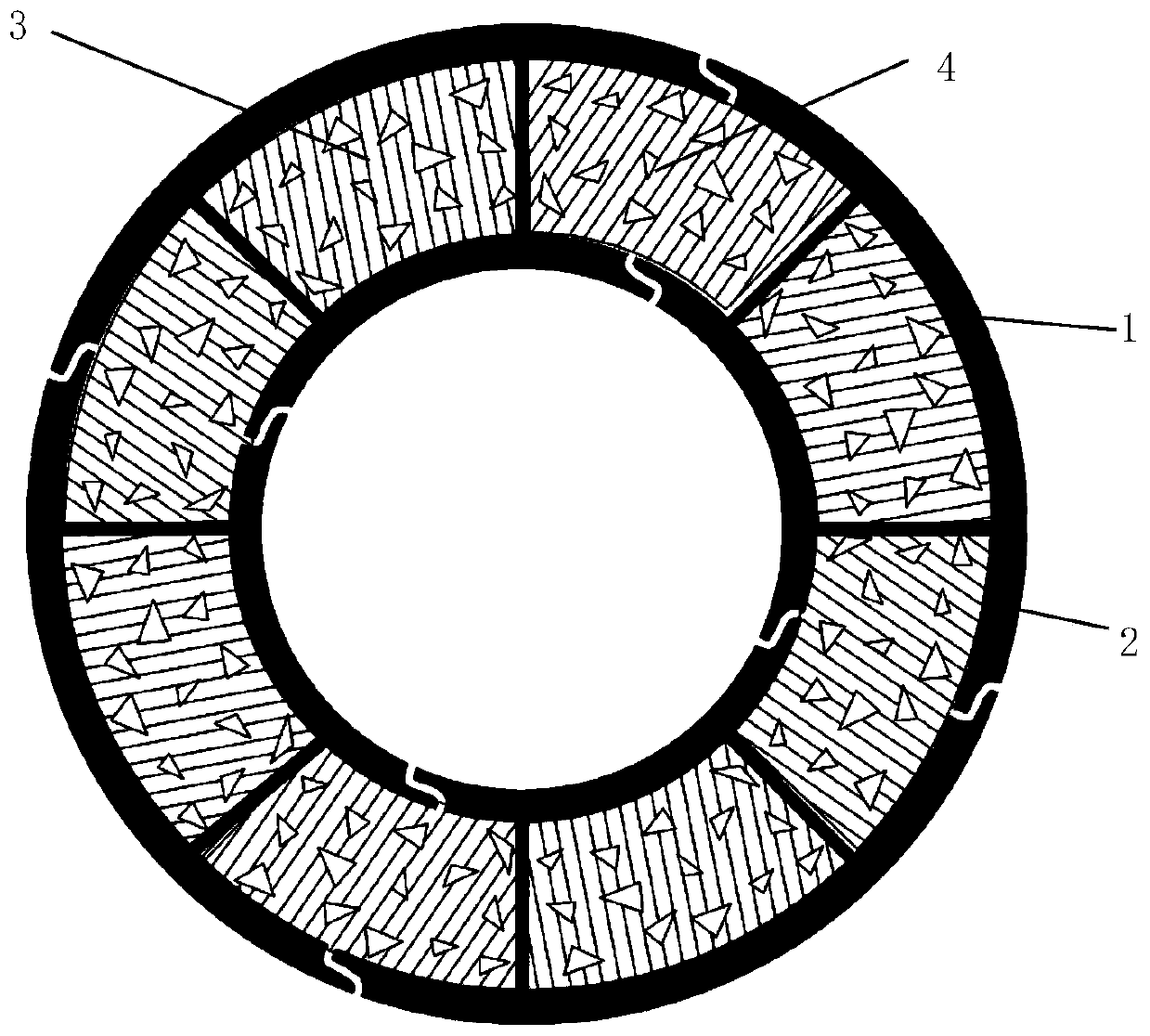

Combined type composite offshore wind power pile and installation method thereof

A composite material and offshore wind power technology, which is applied in sheet pile walls, buildings, infrastructure engineering, etc., can solve the problems of short service life of offshore wind power steel pile structures, increase the cost of maintenance and replacement of wind turbines, and easy corrosion, and achieve simple and convenient installation methods , considerable economic benefits, and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

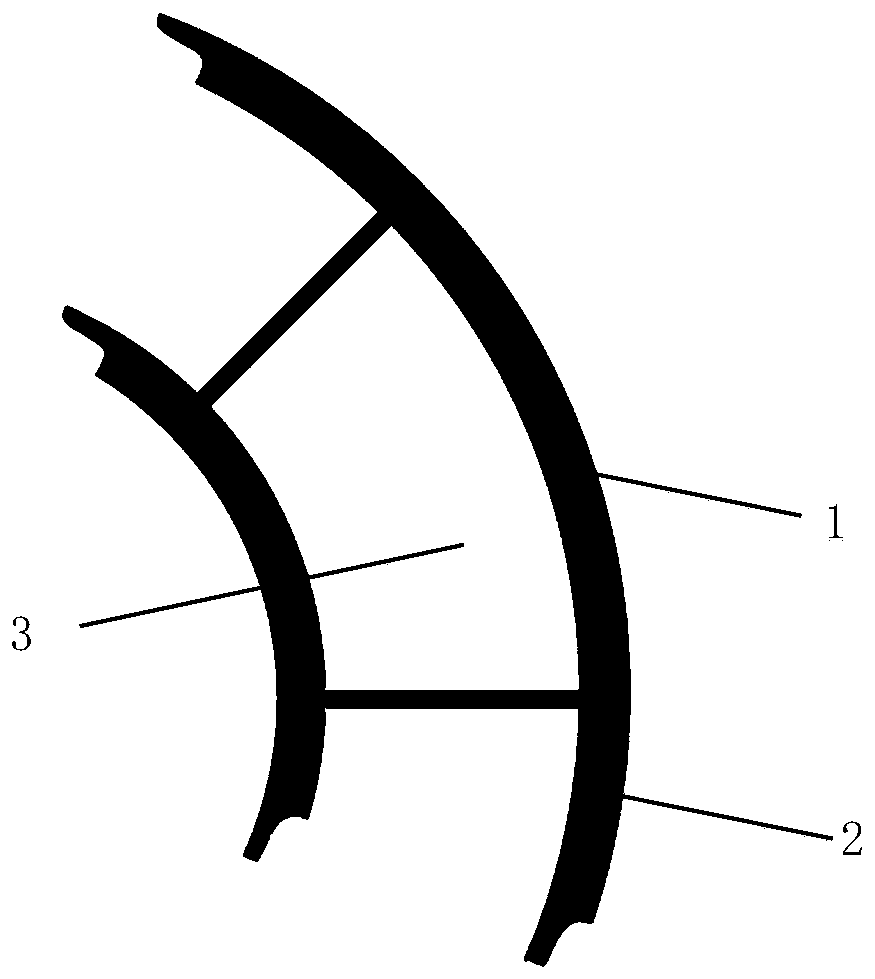

[0034] see figure 2 , the connecting portion 2 is provided with bolt holes for installing bolts when two arc plates 1 are spliced and installed, and each adjacent two arc plates 1 are fixed into a whole by self-locking one-way bolts.

Embodiment 2

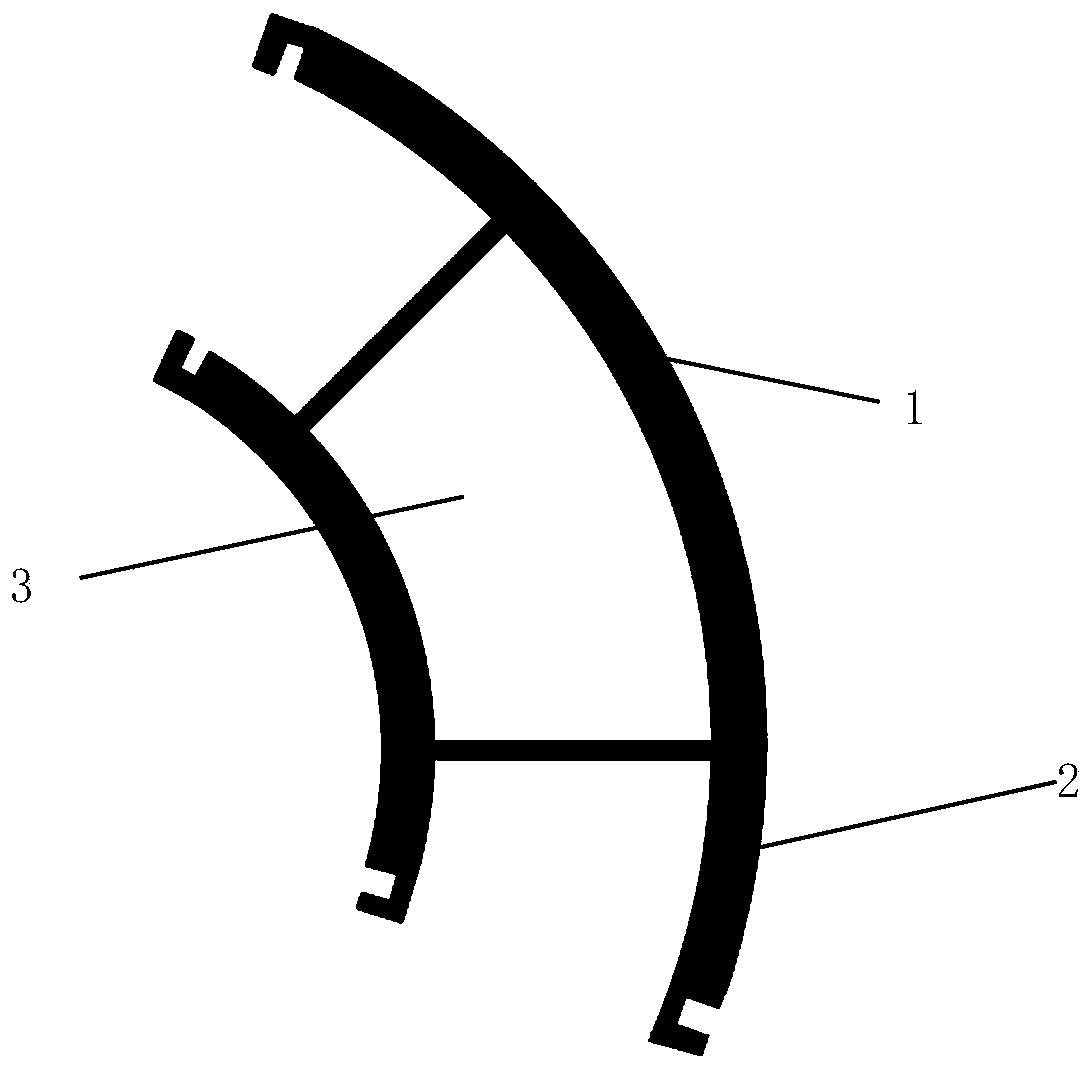

[0036] see image 3 , The connecting part 2 is provided with a groove, and every two adjacent circular arc plates 1 are installed as a whole through socket mechanical connection.

[0037] During installation, after the pile body is driven into the soil with a pile driver, the first cavity and the second cavity are filled with resin concrete mortar, or can be filled with FRP solid waste from the factory, or fiber reinforced plastic factory After the waste is crushed to a certain particle size, it is mixed with resin and filled into the first cavity and the second cavity. Because the waste from fiber-reinforced plastic factories is difficult to degrade and is not good for the environment, when the waste from fiber-reinforced plastic factories is used as fillers, Can play the effect of green environmental protection.

[0038] A method for installing a combined composite material offshore wind power pile of the present invention comprises the following steps:

[0039] (1) Prefab...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap