Binary pouch bag packaged freeze-crack paste composition aerosol and preparation method thereof

A technology of composition and aerosol, applied in the field of aerosol of frozen cream composition in binary pouch packaging and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

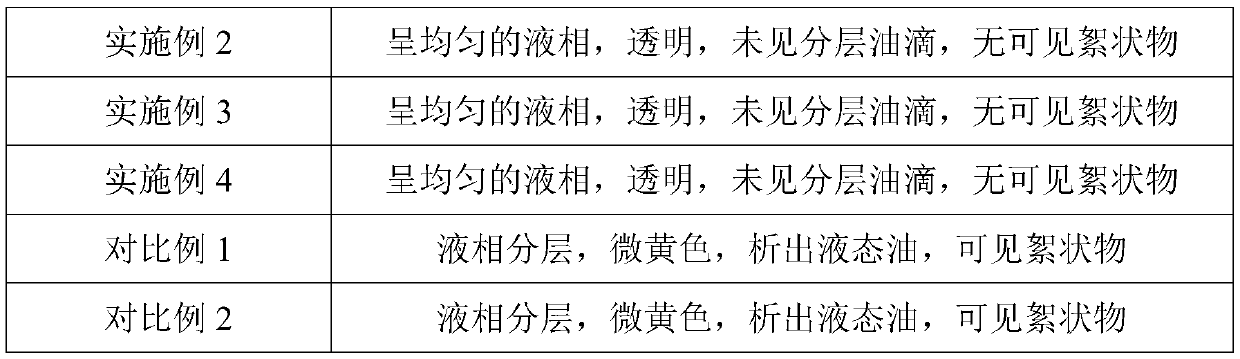

Examples

Embodiment 1

[0029] Other reagents used in the present invention are commonly used reagents, and can be purchased at conventional reagent production and sales companies. Embodiment 1 A kind of binary sachet packaging frozen cracking cream composition aerosol

[0030] The aerosol of the frozen cracking cream composition in binary pouch packaging is composed of the following components and their mass percentages: 98.81% of petrolatum, 0.01% of hemp leaf extract, 0.01% of hemp seed oil, guaiazulene sulphur Sodium Acid 0.05%, Emollient 0.51%, Ceramide 6II 0.1%, Methyl Methacrylate Crosspolymer 0.1%, Solubilizer 0.2%, Vitamin E 0.01%, Diethylenetriamine Pentamethylene Sodium Phosphonate 0.05%, Sodium Glucoheptonate 0.05%, Essence 0.1%.

[0031] The solubilizer is composed of glyceryl stearate citrate and PPG-13-decyl tetradeceth-24 in a weight ratio of 0.1:6.

[0032] The emollient is composed of coconut oil-caprylate / caprate and phytosterol / octyldodecyl lauroyl glutamate in a weight ratio of...

Embodiment 2

[0036] Embodiment 2 A kind of binary sachet packaging frozen cracking cream composition aerosol

[0037] The aerosol of the frozen cracking cream composition in binary sachets is composed of the following components and their mass percentages: 70% of petrolatum, 3% of hemp leaf extract, 3.5% of hemp seed oil, guaiazulene Sodium Acid 0.3%, Emollient 6%, Ceramide 6II 1.2%, Methyl Methacrylate Crosspolymer 5%, Solubilizer 7%, Vitamin E 3.5%, Diethylenetriaminepentamethylenephosphine 0.1% sodium glucoheptonate, 0.1% sodium glucoheptonate, 0.3% essence.

[0038] The solubilizer is composed of glyceryl stearate citrate and PPG-13-decyltetradeceth-24 in a weight ratio of 3:4.

[0039] The emollient is composed of coconut oil-caprylate / caprate and phytosterol / octyldodecyl lauroyl glutamate in a weight ratio of 5:3.

[0040] The preparation method of the described binary sachet packaging freeze cracking paste composition aerosol, the preparation steps are as follows:

[0041] S1. He...

Embodiment 3

[0043] Embodiment 3 A kind of binary pouch packaging frozen cracking cream composition aerosol

[0044] The aerosol of the frozen cracking cream composition in binary pouch packaging is composed of the following components and their mass percentages: 50.3% petrolatum, 5% hemp leaf extract, 5% hemp seed oil, guaiazulene sulphur Sodium Acid 0.4%, Emollient 10%, Ceramide 6II 2%, Methyl Methacrylate Crosspolymer 10%, Solubilizer 10%, Vitamin E 5%, Diethylenetriaminepentamethylenephosphine 0.15% sodium gluconate, 0.15% sodium glucoheptonate, 2% essence.

[0045] The solubilizer is composed of glyceryl stearate citrate and PPG-13-decyl tetradeceth-24 in a weight ratio of 4:0.1.

[0046] The emollient is composed of coconut oil-caprylate / caprate and phytosterol / octyldodecyl lauroyl glutamate in a weight ratio of 6:0.01.

[0047] The preparation method of the described binary sachet packaging freeze cracking paste composition aerosol, the preparation steps are as follows:

[0048] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com