Ultrathin asphalt mixture based on environment-friendly rubber powder and preparation method thereof

A technology of asphalt mixture and environmentally friendly rubber, applied in the field of road engineering materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

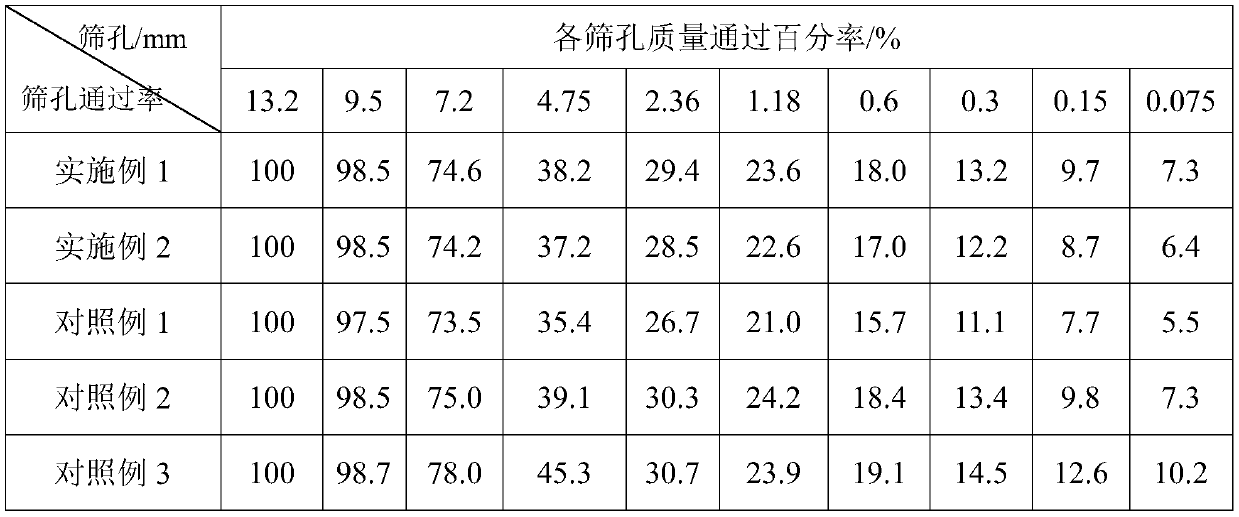

Embodiment 1

[0033] 1. Ultra-thin asphalt mixture based on environmentally friendly rubber powder

[0034] The above-mentioned ultra-thin asphalt mixture based on environmental protection rubber powder comprises the following raw materials in parts by weight:

[0035] 88.2% aggregate, 6.5% limestone powder, 0.3% basalt fiber and 5.0% environmentally friendly rubber powder modified asphalt.

[0036] Among them, the environment-friendly rubber powder modified asphalt is obtained by shearing and mixing the environment-friendly rubber powder and base asphalt at 180°C, and the ratio of environment-friendly rubber powder and base asphalt is 0.22:1. The base asphalt is Esso 70# base asphalt that meets the requirements of JTG F40-2004 "Technical Specifications for Asphalt Pavement Construction of Highway Engineering". The environmentally friendly rubber powder is produced by Jiangsu Zhonghong Environmental Protection Technology Co., Ltd. with a sulfur content of 0.35% and a carbon black content of...

Embodiment 2

[0045] The ultra-thin asphalt mixture based on the environment-friendly rubber powder of the present embodiment comprises the following raw materials in parts by weight:

[0046] 87.8% of aggregate, 6.7% of limestone powder, 0.3% of lignin fiber and 5.2% of environmentally friendly rubber powder modified asphalt.

[0047]Among them, the environment-friendly rubber powder modified asphalt is obtained by shearing and mixing the environment-friendly rubber powder and base asphalt at 180°C, and the ratio of environment-friendly rubber powder and base asphalt is 0.27:1. The base asphalt is Shell 90# base asphalt that meets the requirements of JTG F40-2004 "Technical Specifications for Asphalt Pavement Construction of Highway Engineering". The environmentally friendly rubber powder is produced by Suzhou Runjieer Environmental Protection New Material Co., Ltd., with a sulfur content of 0.41%. The carbon black content is 41%, the rubber hydrocarbon content is 39%, and the tensile stre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com