Isobutylene oligomerization method

An isobutylene and titanium-based technology, applied in chemical instruments and methods, hydrocarbons, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of low dimer selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

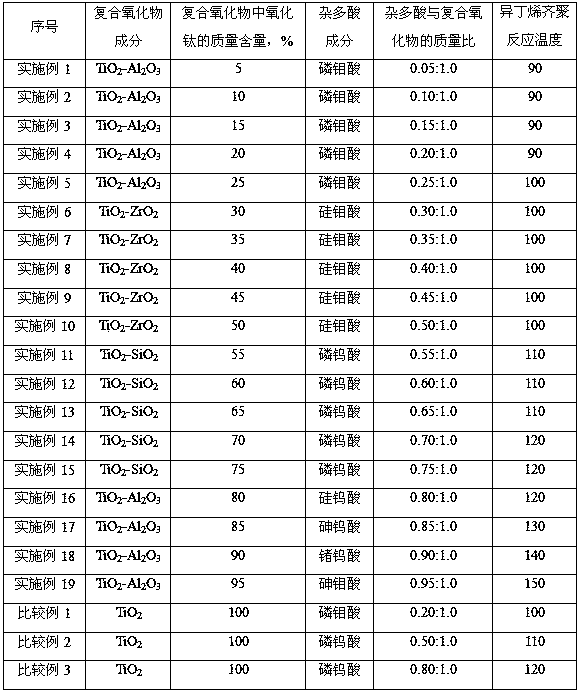

[0028] (1) Prepare 20g of aluminum nitrate and 25g of titanium tetrachloride into an aqueous solution a with a mass concentration of 25%, and then prepare a potassium hydroxide alkaline solution b with a mass concentration of 20%, and dissolve the Solution b was added dropwise to solution a, reacted for 10 hours to obtain a white paste precipitate, washed, filtered, dried at 120°C for 10 hours, then extruded according to the conventional method, and then roasted at 500°C for 8 hours to obtain a titanium-based composite oxide carrier.

[0029] (2) Dissolve 15g of phosphomolybdic acid in 200mL of deionized water, and immerse the above-mentioned shaped and roasted catalyst carrier in the heteropolyacid solution for 8 hours, and dry the impregnated material at 120°C for 10 hours, Calcined for 10 hours, the catalyst was prepared, and the composition of the catalyst is shown in Table 1.

[0030] (3) The prepared catalyst is used for the oligomerization of isobutene. The reaction is...

Embodiment 2-5

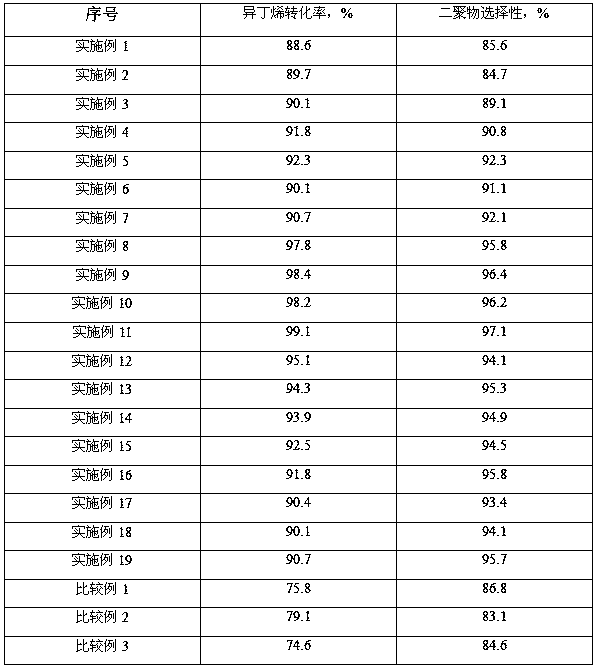

[0032]Other conditions are the same as in Example 1, except that the consumption of aluminum nitrate and phosphomolybdic acid is changed to obtain catalysts of different compositions, see Table 1, adjust the reaction temperature when used for isobutylene oligomerization, specifically see Table 1, isobutylene conversion rate and dimerization The results of material selectivity are shown in Table 2.

Embodiment 6

[0034] Other conditions are the same as in Example 1, except that aluminum nitrate is changed into zirconium tetrachloride, phosphomolybdic acid is changed into silicomomolybdic acid, and catalysts of different components and compositions are obtained, as shown in Table 1, and the results for isobutylene oligomerization are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com