Method for preparing camellia-oil fatty acid esters

A technology of oil fatty acid ester and camellia oil, which is applied in the field of preparation of camellia oil fatty acid ester, and can solve problems such as slow reaction rate and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

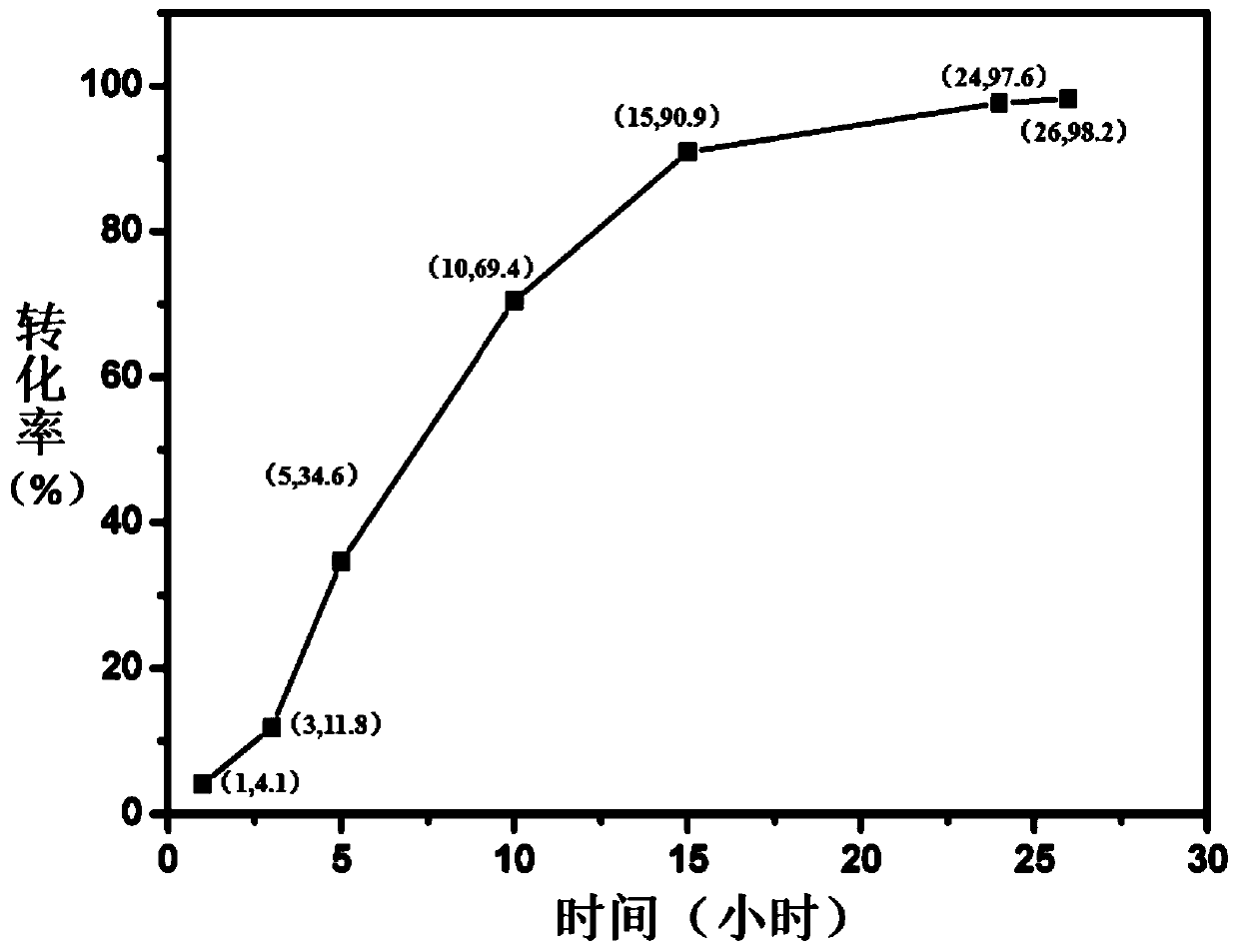

Embodiment 1

[0025] This embodiment provides a method for preparing camellia oil fatty acid ethyl ester, which includes the following steps: adding a biological enzyme catalyst to a mixed solution of camellia oil, alcohol and a cosolvent, and performing an esterification reaction to obtain camellia oil fatty acid ester.

[0026] The alcohol is selected from ethanol; the biological enzyme catalyst is selected from NOVOZYM435 immobilized lipase; camellia oil is refined tea oil that has been degummed, deacidified, decolorized, and deodorized, in which oleic acid accounts for 81%, linoleic acid accounts for 10%, Palmitic acid accounts for 7%, stearic acid accounts for 1.2%, and linolenic acid accounts for 0.3%; the cosolvent is selected from camellia oil fatty acid ethyl ester; and the mass ratio of camellia oil to alcohol is 5.53:1, and the mass ratio of cosolvent to camellia oil The mass ratio of biological enzyme catalyst to camellia oil is 0.04:1.

[0027] Specifically, 11.5 g of camellia ...

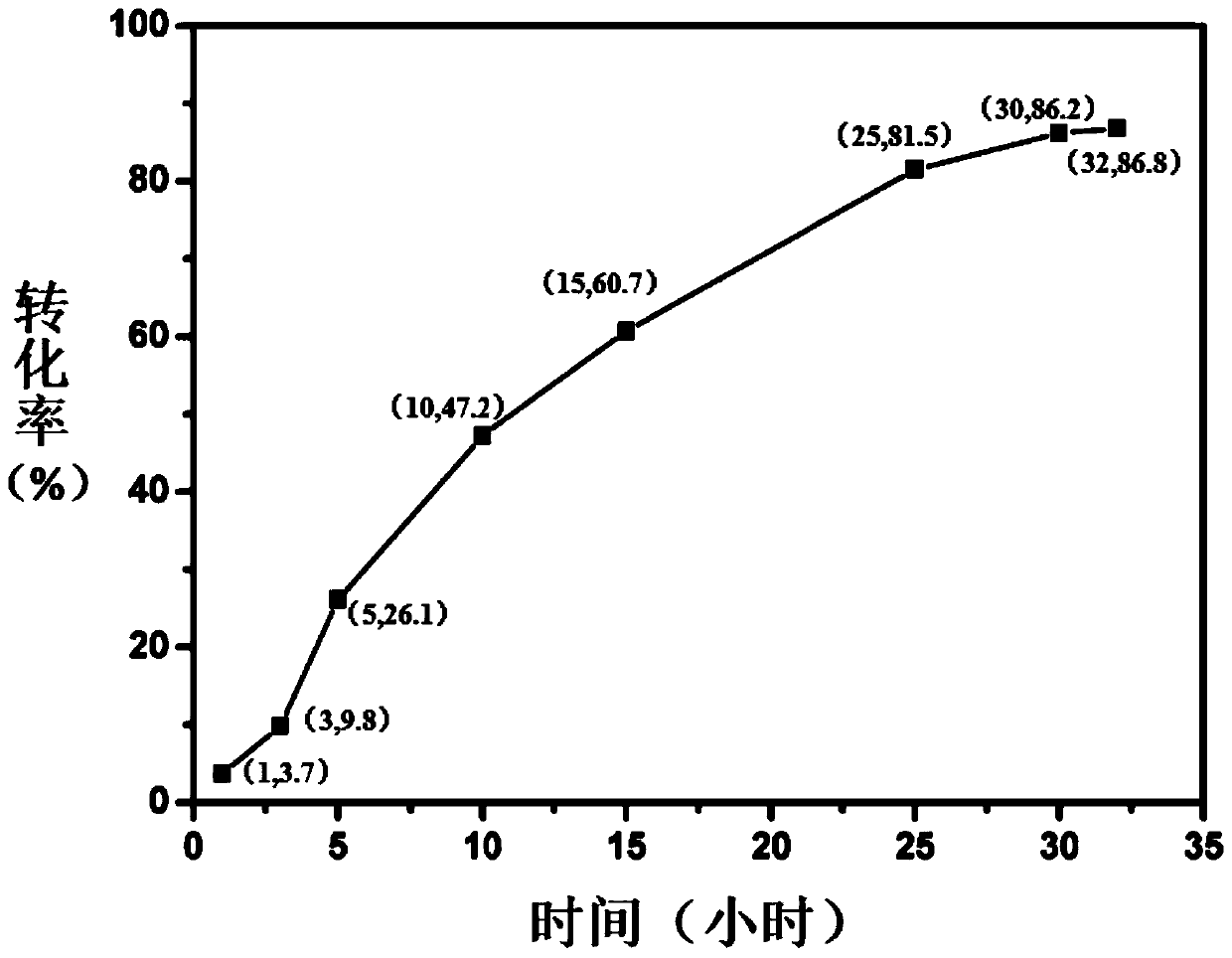

Embodiment 2

[0033] This embodiment provides a method for preparing camellia oil fatty acid triglyceride, which includes the following steps: adding a biological enzyme catalyst to a mixed solution of camellia oil, alcohol and co-solvent, and performing esterification to obtain camellia oil fatty acid ester.

[0034] Among them, the alcohol is selected from glycerol; camellia oil is the refined camellia oil that has been degummed, deacidified, decolorized and deodorized, in which oleic acid accounts for 81%, linoleic acid accounts for 10%, palmitic acid accounts for 7%, stearic acid Accounted for 1.2%, linolenic acid accounted for 0.3%; biological enzyme catalyst selected from NOVOZYM435 immobilized lipase, co-solvent selected from camellia oil fatty acid triglyceride; and the mass ratio of camellia oil to alcohol is 9.2:1, co-solvent and camellia oil The mass ratio is 0.69:1, and the mass ratio of biological enzyme catalyst to camellia oil is 0.04:1.

[0035] Specifically, 11.5g camellia ...

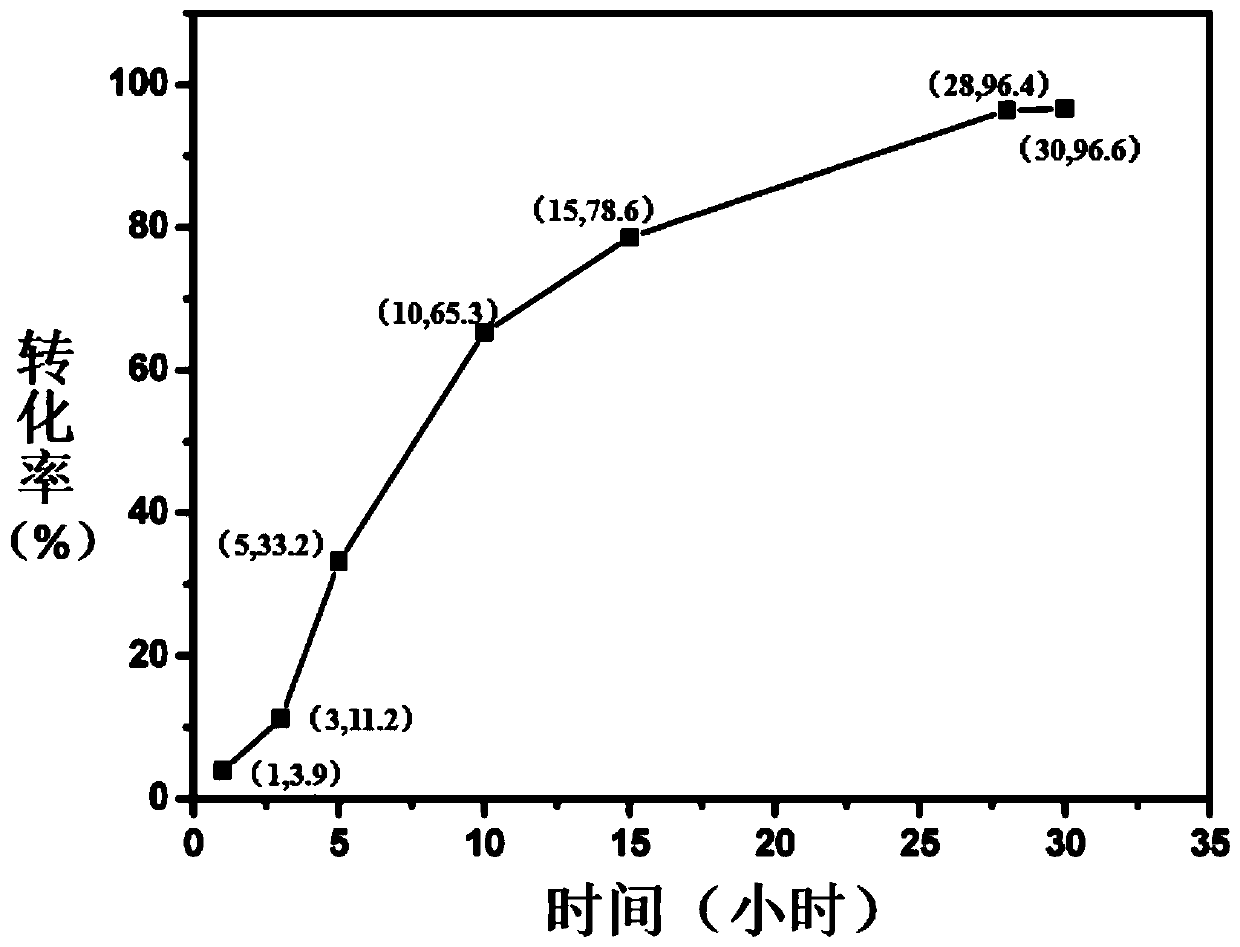

Embodiment 3

[0039] This embodiment provides a method for preparing camellia oil fatty acid octyl ester, which includes the following steps: adding a biological enzyme catalyst to a mixed solution of camellia oil, alcohol and co-solvent, and performing esterification to obtain camellia oil fatty acid ester.

[0040] Among them, alcohol is selected from octanol; camellia oil is refined camellia oil that has been degummed, deacidified, decolorized, and deodorized, in which oleic acid accounts for 81%, linoleic acid accounts for 10%, palmitic acid accounts for 7%, and stearic acid accounts for 7%. 1.2%, linolenic acid accounts for 0.3%; biological enzyme catalyst is selected from NOVOZYM435 immobilized lipase, co-solvent is selected from camellia oil fatty acid octyl ester; and the mass ratio of camellia oil to alcohol is 1.97:1, the mass ratio of co-solvent to camellia oil The ratio is 0.63:1, and the mass ratio of biological enzyme catalyst to camellia oil is 0.04:1.

[0041] Specifically, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com