Quantum dot light-emitting diode

A quantum dot light-emitting and diode technology, which is applied to electrical components, circuits, organic semiconductor devices, etc., can solve the problems of decreased electron injection ability, decreased efficiency of quantum dot light-emitting diodes, and reduced number of electrons.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

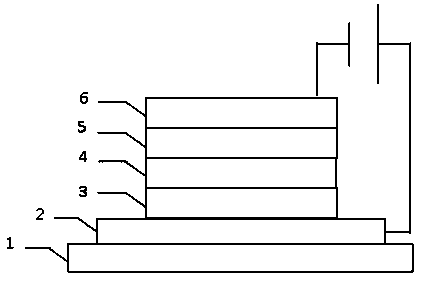

[0042] To figure 1 The structure shown is an example. The embodiment of the present invention also provides a method for manufacturing a quantum dot light emitting diode, which includes the following steps:

[0043] Provide anode;

[0044] Preparing a hole transport layer on the anode;

[0045] Preparing a quantum dot light-emitting layer on the hole transport layer;

[0046] An electron transport layer is prepared on the quantum dot light-emitting layer; wherein, the preparation method of the electron transport layer specifically includes the steps of: preparing an inorganic layer on the quantum dot light-emitting layer, preparing a metal layer on the inorganic layer, and Preparing an organic layer on the metal layer;

[0047] A cathode is prepared on the electron transport layer.

[0048] In a preferred embodiment, in order to accelerate the alloying effect between the metal and the inorganic metal oxide, the prepared quantum dot light-emitting diode can be heated. More preferably, t...

Embodiment 1

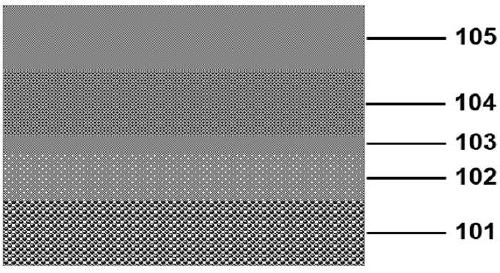

[0054] Example 1: Combination figure 2 As shown, the method for preparing a quantum dot light-emitting diode based on an inorganic / metal / organic composite structure electron transport layer includes the following steps:

[0055] Using ITO as the anode, in an air environment, deposit 30nm thick PEDOT:PSS as a hole injection layer on the ITO surface by solution method, and annealed at 150℃ for 10 minutes;

[0056] N 2 Under the environment, deposit 30nm thick TFB as a hole transport layer on the surface of the hole injection layer by solution method, and annealed at 150°C for 30 minutes;

[0057] N 2 Under the environment, deposit 25nm thick CdSe / ZnS quantum dots as the quantum dot light-emitting layer on the surface of the hole transport layer by solution method, and annealed at 100°C for 30 minutes;

[0058] N 2 Under the environment, deposit 15nm thick ZnO as an inorganic layer on the surface of the quantum dot light-emitting layer by solution method, and annealed at 80°C for 30 minu...

Embodiment 2

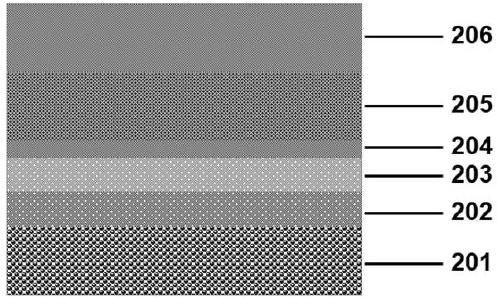

[0063] Example 2: Combination image 3 As shown, the method for preparing a quantum dot light emitting diode based on an inorganic / inorganic metal / metal / organic composite structure electron transport layer includes the following steps:

[0064] Using ITO as the anode, in an air environment, deposit 30nm thick PEDOT:PSS as a hole injection layer on the ITO surface by solution method, and annealed at 150℃ for 10 minutes;

[0065] N 2 Under the environment, deposit 30nm thick TFB on the surface of the hole injection layer as a hole transport layer by solution method, and annealed at 150°C for 30 minutes;

[0066] N 2 Under the environment, deposit 25nm thick CdSe / ZnS quantum dots on the surface of the hole transport layer as the quantum dot light-emitting layer by solution method, and annealed at 100°C for 30 minutes;

[0067] Transfer the above-mentioned substrates to the evaporation chamber, and vacuum to Pa is below Pa, and then 5nm thick ZnO is deposited as an inorganic layer at a sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com