A kind of bone cement composite material and preparation method thereof

A composite material and bone cement technology, which is applied in the field of medical materials, can solve the problems of poor bonding and poor stability of acrylic resin bone cement, and achieve the effects of promoting wound healing, high stability, and improving biological safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

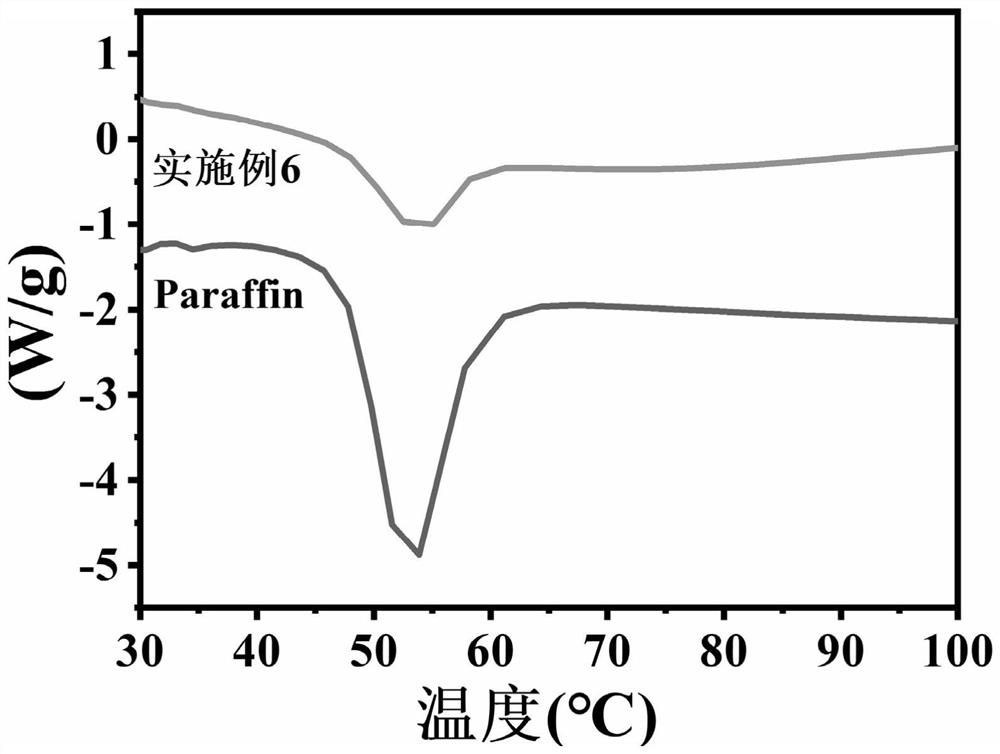

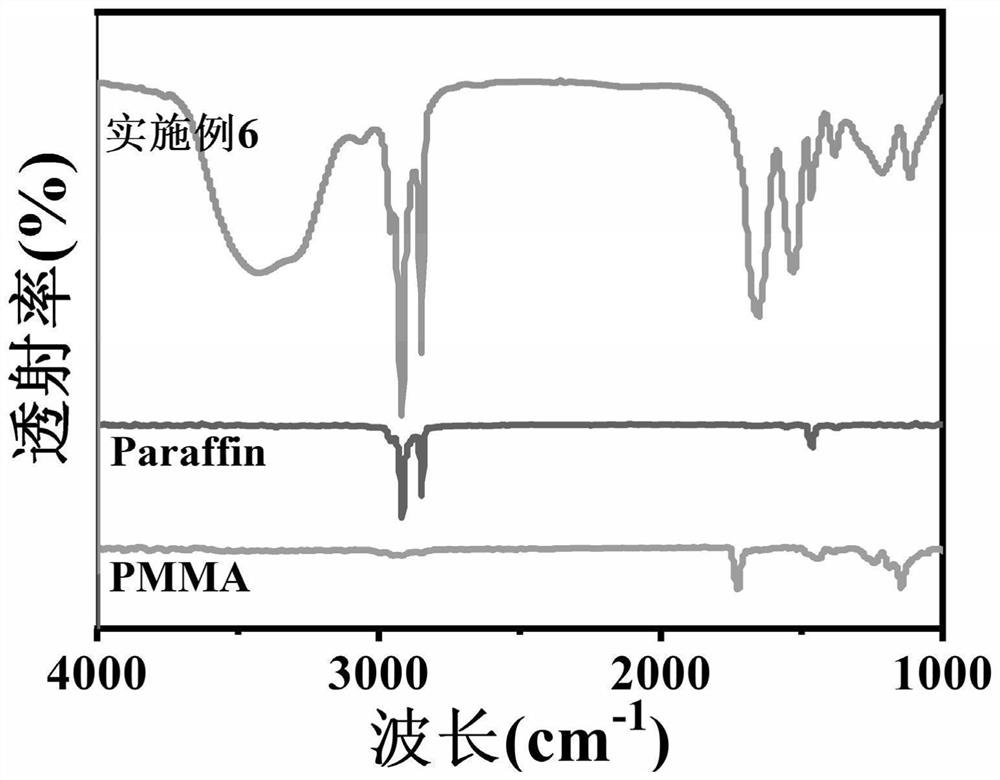

[0042] The bone cement composite material of this embodiment includes: a solid phase component and a liquid phase component, and the mass ratio of the solid phase component and the liquid phase component is 2:1;

[0043] Wherein, the solid phase components include: methyl methacrylate copolymer, paraffin wax / polymethyl methacrylate-methylenebisacrylamide phase change microcapsules, in the solid phase components, methyl methacrylate copolymer The mass fraction of paraffin wax / polymethyl methacrylate-methylenebisacrylamide phase change microcapsules is 30%; the liquid phase component includes methyl methacrylate.

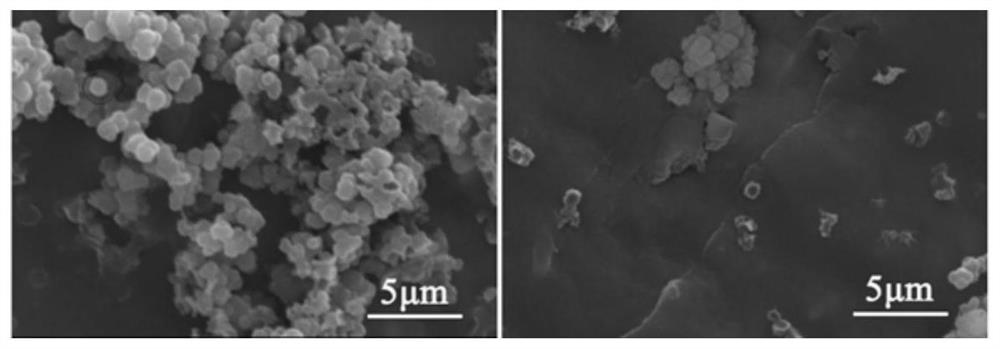

[0044] Wherein, the preparation method of paraffin / polymethyl methacrylate-methylenebisacrylamide variable microcapsules comprises the following steps:

[0045] (1) After mixing methyl methacrylate, paraffin and cross-linking agent with water, heat in a water bath at 40°C, stir at 3000rpm for 10 minutes, add emulsifier and continue to stir and shear emulsify at 3000rp...

Embodiment 2

[0053] The bone cement composite material of this embodiment includes: a solid phase component and a liquid phase component, and the mass ratio of the solid phase component and the liquid phase component is 2:1;

[0054] Wherein, the solid phase components include: methyl methacrylate copolymer, paraffin wax / polymethyl methacrylate-methylenebisacrylamide phase change microcapsules, in the solid phase components, methyl methacrylate copolymer The mass fraction of paraffin wax / polymethyl methacrylate-methylenebisacrylamide phase change microcapsules is 20%;

[0055] The liquid phase component includes methyl methacrylate.

[0056] Wherein, the preparation method of paraffin / polymethyl methacrylate-methylenebisacrylamide phase-change microcapsules comprises the following steps:

[0057] (1) After mixing methyl methacrylate, paraffin and crosslinking agent with water, heat in a water bath at 50°C, stir at 5000rpm for 15min, add emulsifier and continue to stir and shear emulsify a...

Embodiment 3

[0065] The bone cement composite material of this embodiment includes: a solid phase component and a liquid phase component, and the mass ratio of the solid phase component and the liquid phase component is 2:1;

[0066] Wherein, the solid phase components include: methyl methacrylate copolymer, paraffin wax / polymethyl methacrylate-methylenebisacrylamide phase change microcapsules, in the solid phase components, methyl methacrylate copolymer The mass fraction of paraffin wax / polymethyl methacrylate-methylenebisacrylamide phase change microcapsules is 10%;

[0067] The liquid phase component includes methyl methacrylate.

[0068] Wherein, the preparation method of paraffin / polymethyl methacrylate-methylenebisacrylamide phase-change microcapsules comprises the following steps:

[0069] (1) After mixing methyl methacrylate, paraffin and cross-linking agent with water, heat in a water bath at 60°C, stir at 8000rpm for 20min, add emulsifier and continue to stir and shear emulsify ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com