Adjustable hollow fiber ultrafiltration system

An ultrafiltration system and adjustable technology, applied in ultrafiltration, membrane, membrane technology and other directions, can solve the problems of inability to maintain a constant volume and multiple ultrafiltration, high cost of modification or replacement, and inability to use together. Efficiency, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The above solution will be further described below in conjunction with specific embodiments.

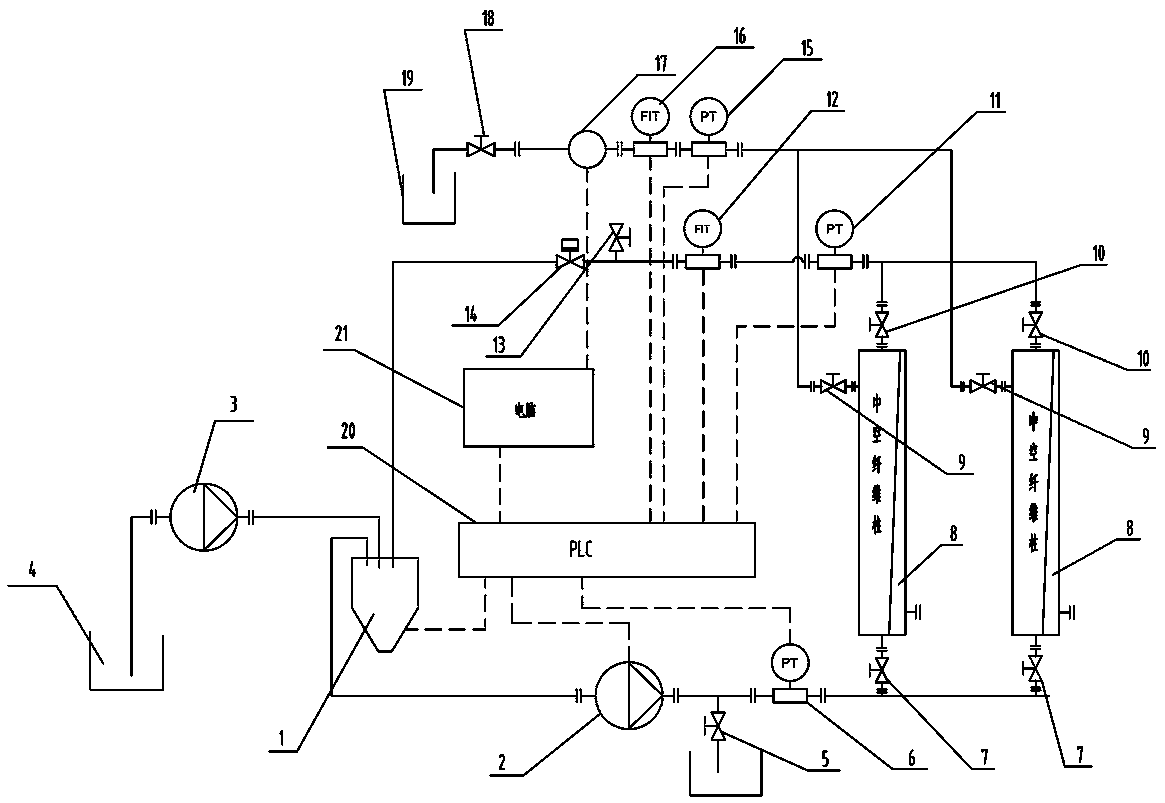

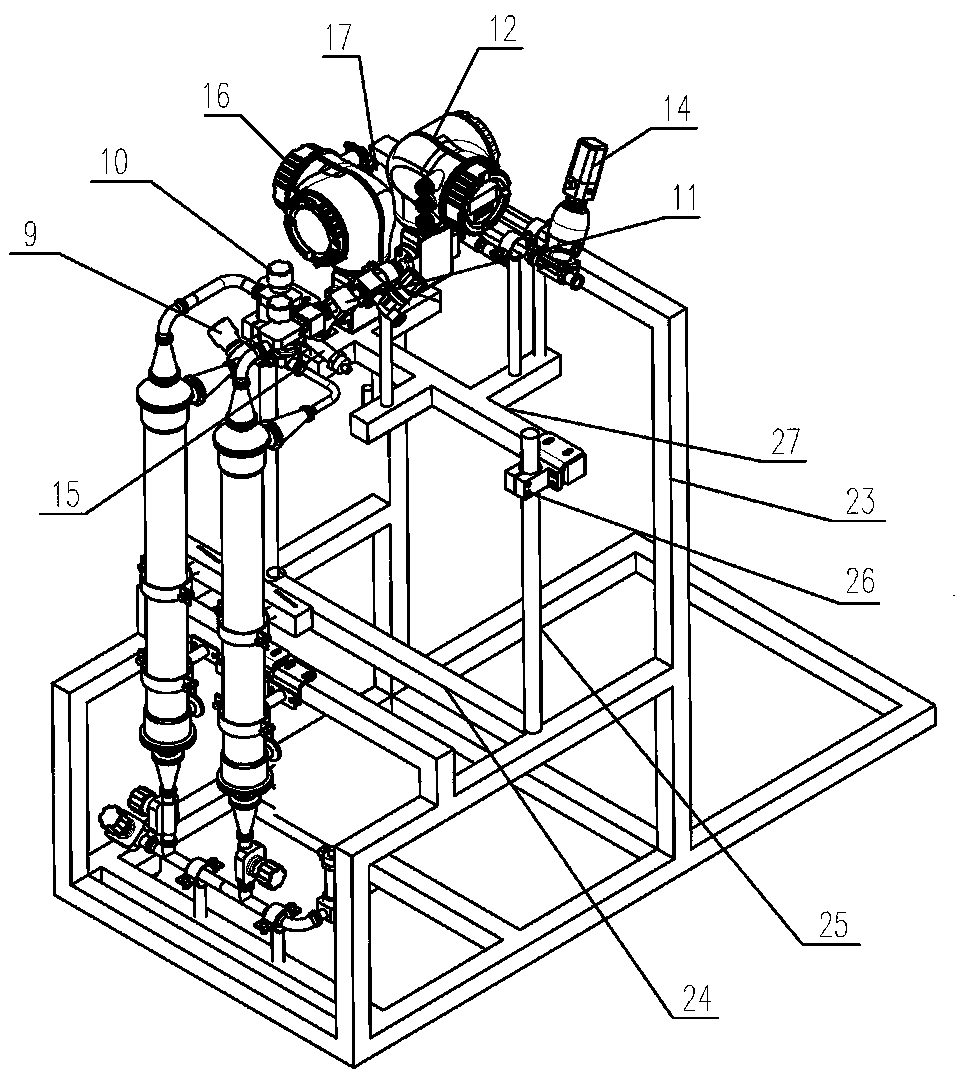

[0025] An adjustable hollow fiber ultrafiltration system, comprising a circulation tank 1, an infusion pump 2, a fluid replacement pump 3, a fluid replacement pool 4, a hollow fiber membrane column 8, a liquid inlet valve 7, a permeation valve 9, a return valve 10, and a first pressure Controller 6, second pressure controller 11, third pressure controller 15, automatic pressure regulating valve 14, controller 20, computer 21, detection device 17, first flow controller 12, second flow controller 16, concentrated Solution collection valve 5 , integrity test valve 13 , support structure 22 , guide shaft 25 , guide shaft support 26 , and moving bracket 27 .

[0026] like figure 1 As shown, the circulation tank 1 is respectively connected with the liquid outlet of the liquid replenishment pump 3 and the liquid inlet of the infusion pump 2, and the liquid inlet of the liquid replen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com