Method for dissolving polymer in solvent and apparatus thereof

A polymer and solvent technology, applied in the direction of dissolving, dissolving, driving the agitator to dissolve, etc., can solve the problems that the axial flow cannot be effectively increased, the screw cannot provide high shear force, and it is difficult to disperse the polymer. Achieve the effect of reducing the amount of material held, reducing the volume of the equipment, and improving the dissolution efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

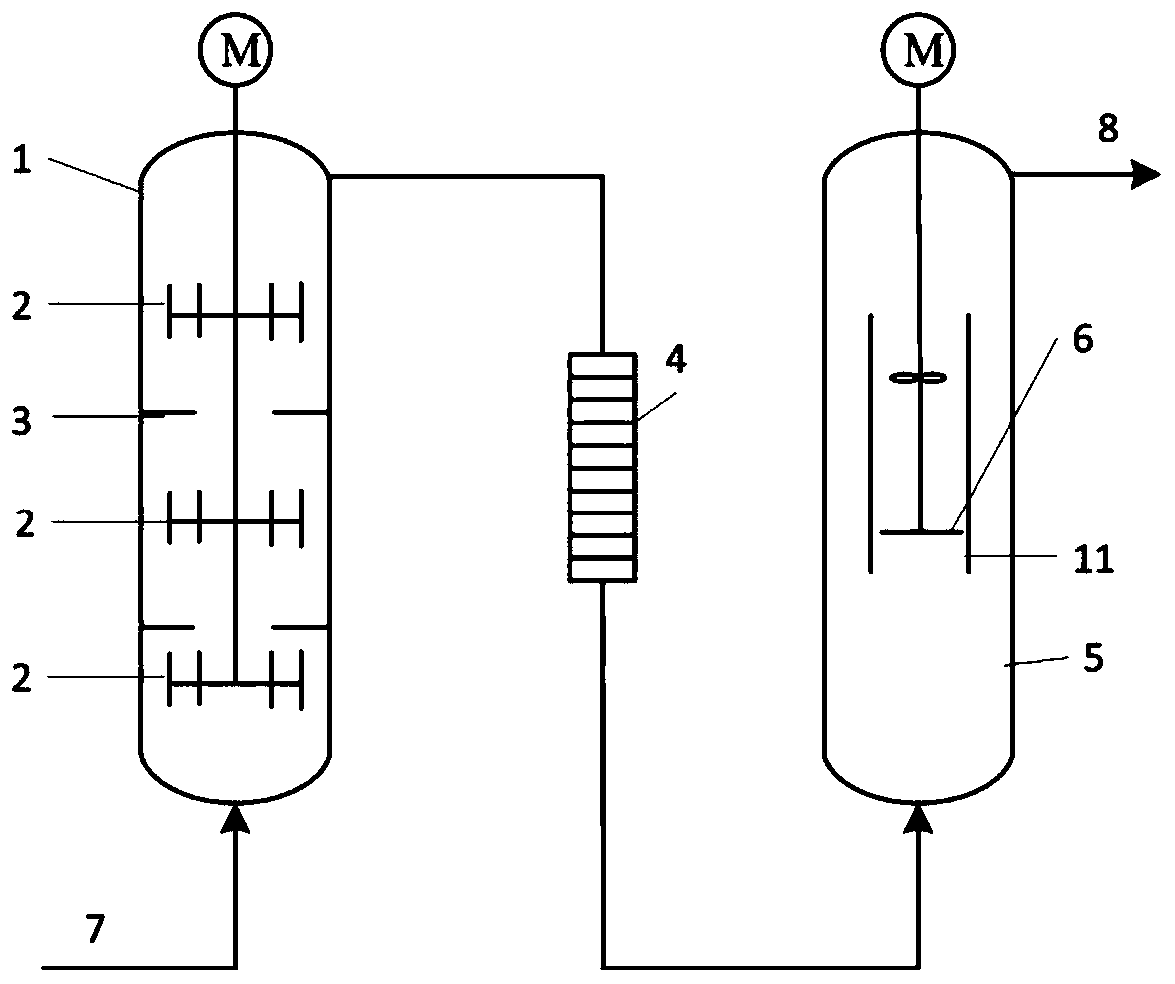

[0089] according to figure 1 The equipment shown is operated, the polymer is linear polyethylene with a melt index of 0.5, the solvent is trifluoromethane, its content is 14%, the mass flow rate is 80 kg / h (volume flow rate is about 70 L / h). The operating temperature of the first-stage workshop and the second-stage workshop are both 185°C, the pressure is 113bar, and the internal volume is 30L. The first stage belongs to the high-shear stirring zone, which has three layers of equal-spaced disc turbine impellers with backward curved impellers, the stirring speed is 500rpm, and the calculated residence time is 26min; the second stage belongs to the axial flow stirring, with two Stirring paddles with the same equidistant distribution in the same layer, one of which is a push-type paddle, and the other is a paddle-type paddle with a draft tube, the stirring speed is 150rpm, and the calculated residence time is 26min.

Embodiment 2

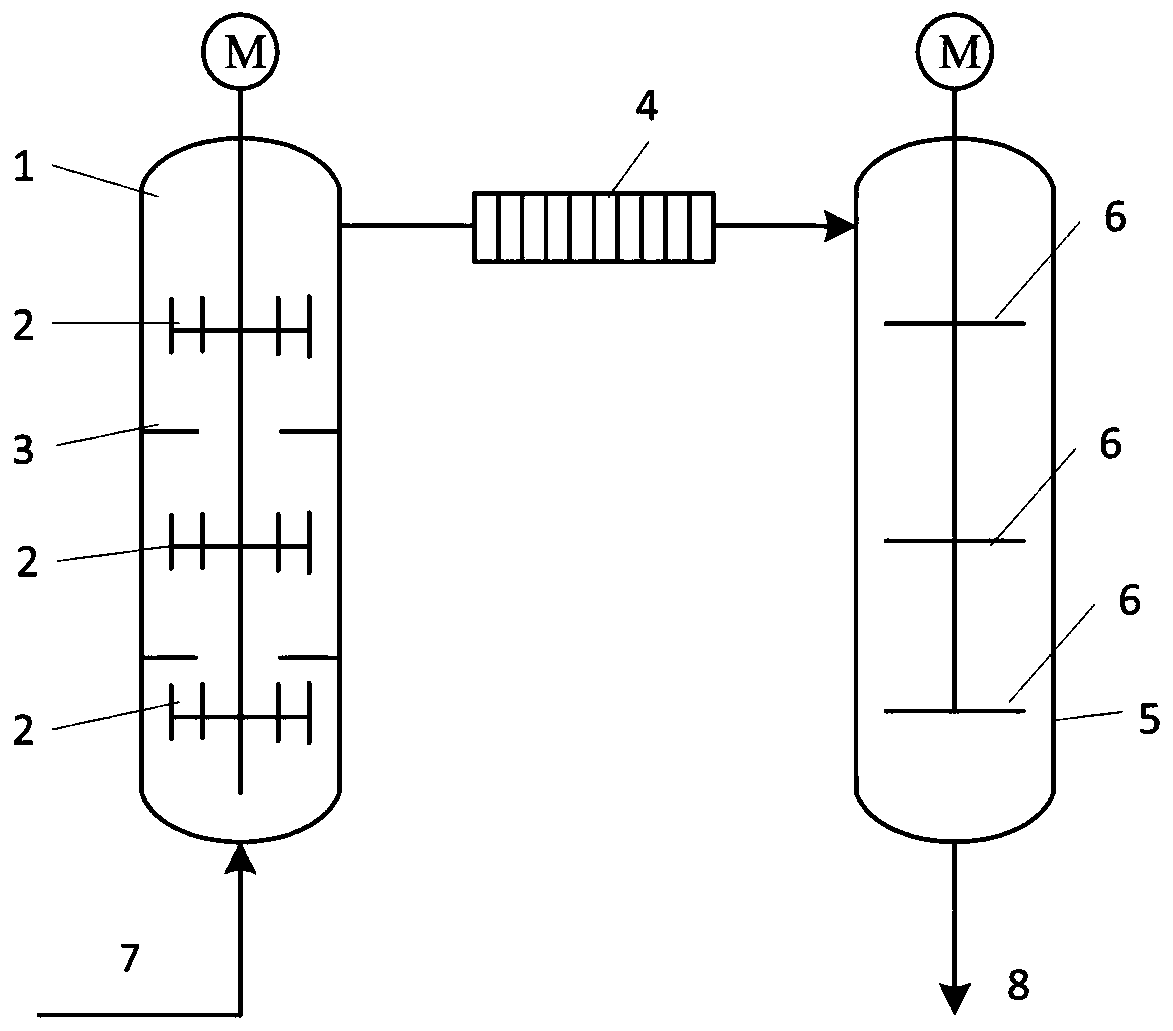

[0091] according to figure 2 The plant shown is operated with a polymer of linear polyethylene (PE) with a melt index of 1, a solvent of trifluoromethane at a content of 15%, and a mass flow rate of 80 kg / h (volume flow rate of about 70 L / h). The operating temperature of the first-stage workshop and the second-stage workshop are both 185°C, the pressure is 150bar, and the internal volume is 15L. The first stage belongs to the high-shear stirring zone, which has three identically spaced disc turbine impellers with straight impellers, the stirring speed is 800rpm, and the calculated residence time is 13min; the second stage belongs to the axial flow stirring, and the internal volume is 30L, there are three layers of the same push-type stirring paddles distributed at equal intervals, the stirring speed is 300rpm, and the calculated residence time is 26min.

Embodiment 3

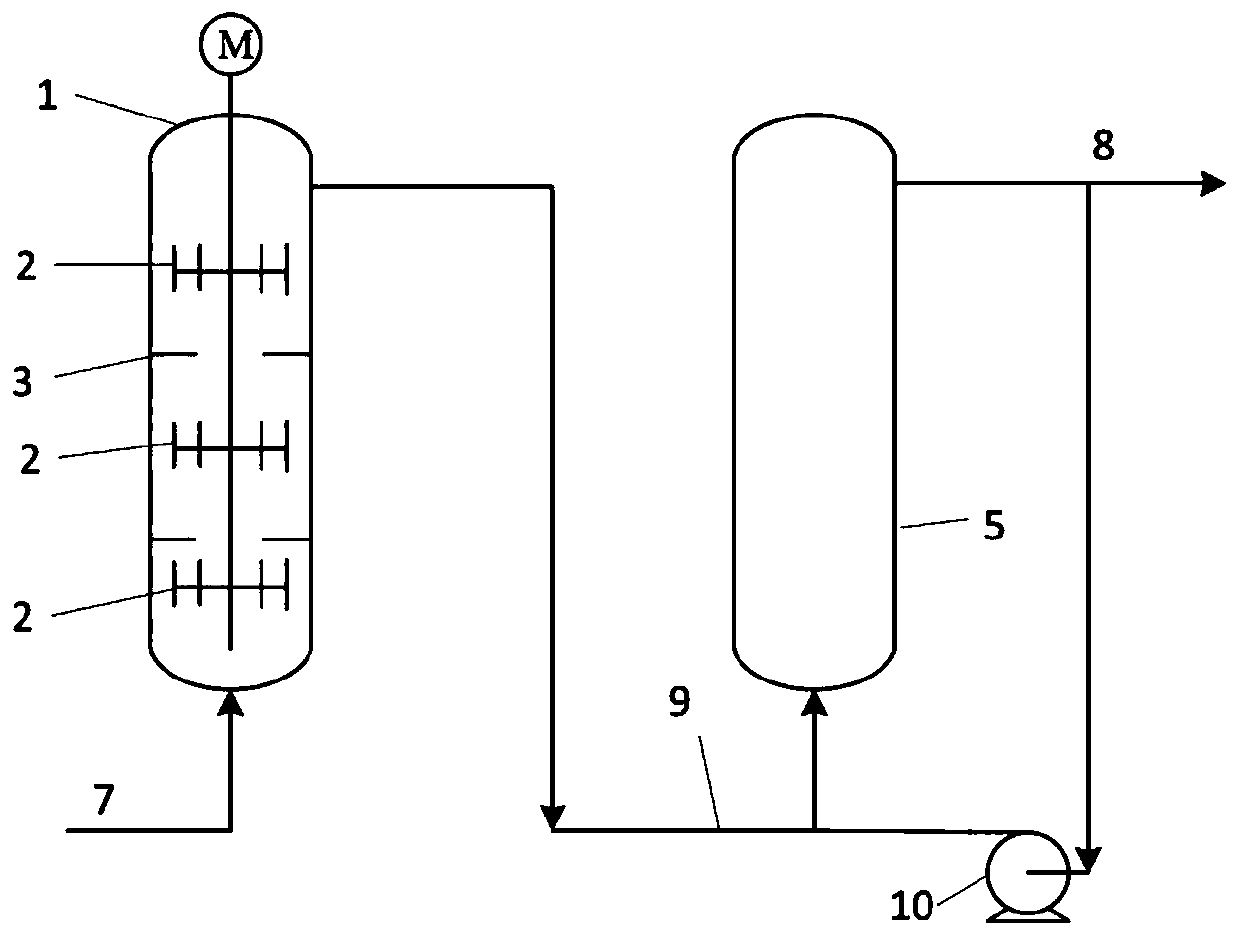

[0093] according to image 3 The equipment shown is operated, the polymer is polypropylene (PP) with a melt index of 3, and the solvent is 1,1-dichloro-2,2,2-trifluoroethane (HC-123) at 10% , the mass flow rate is 80kg / h (the volume flow rate is about 70L / h). The operating temperature of the first-stage workshop and the second-stage workshop are both 150°C, the pressure is 220bar, and the internal volume is 30L. The first stage belongs to the high-shear stirring zone, with three layers of equally spaced semi-pipe disc turbine impellers, the stirring speed is 800rpm, and the calculated residence time is 26min; the second-stage equipment is hollow, and the calculated residence time is 26min. The circulating pump adopts a closed pump with a flow rate of 300L / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com