Preparation method of self-crosslinking sulfonated polyimide film

A sulfonated polyimide membrane and self-crosslinking technology, which can be used in energy storage, electrochemical generators, bulk chemical production, etc., can solve the problem of unfavorable sulfonated polyimide membrane proton conduction and membrane chemical stability It is difficult to significantly improve or affect polymer film formation and physical and chemical properties, so as to improve proton transfer ability and solve the effect of weak chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

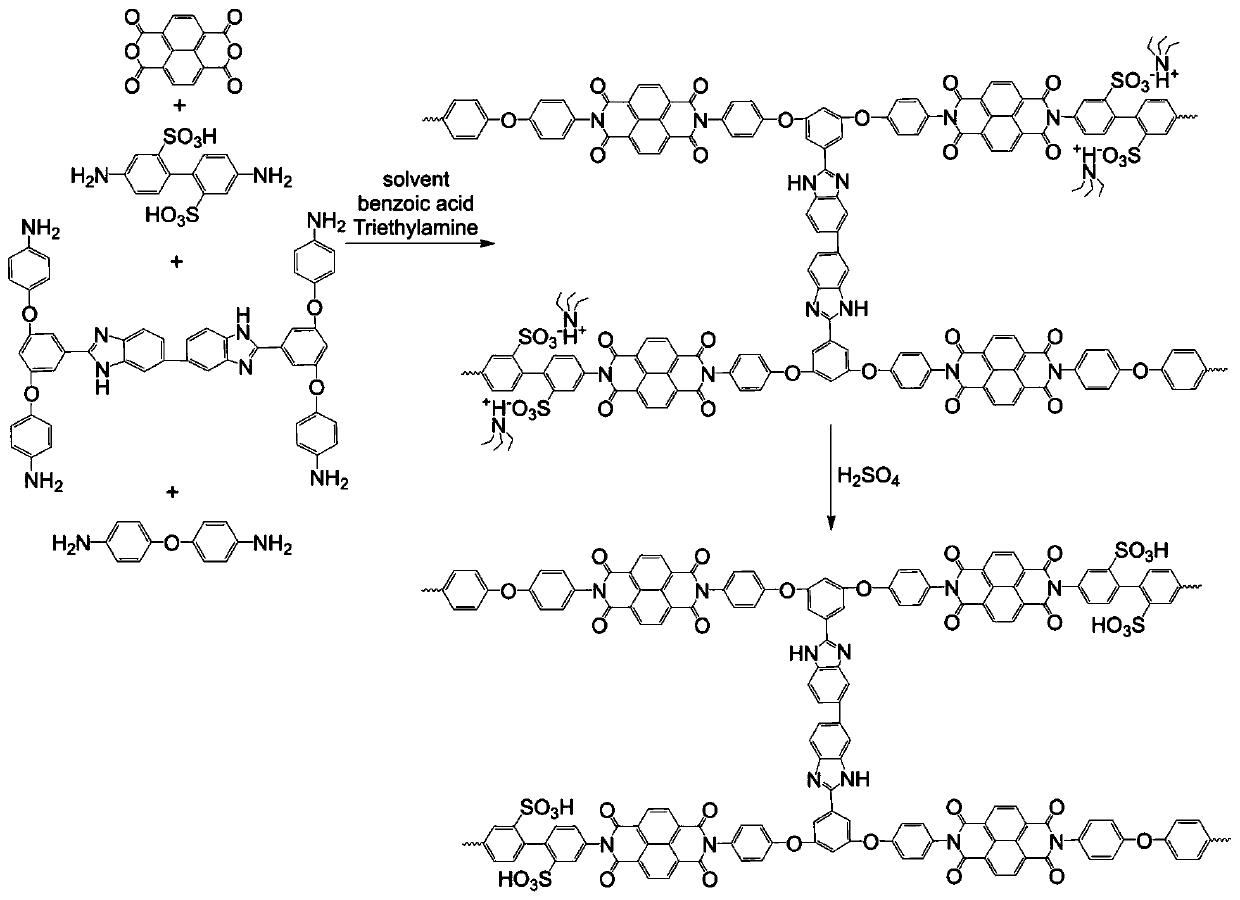

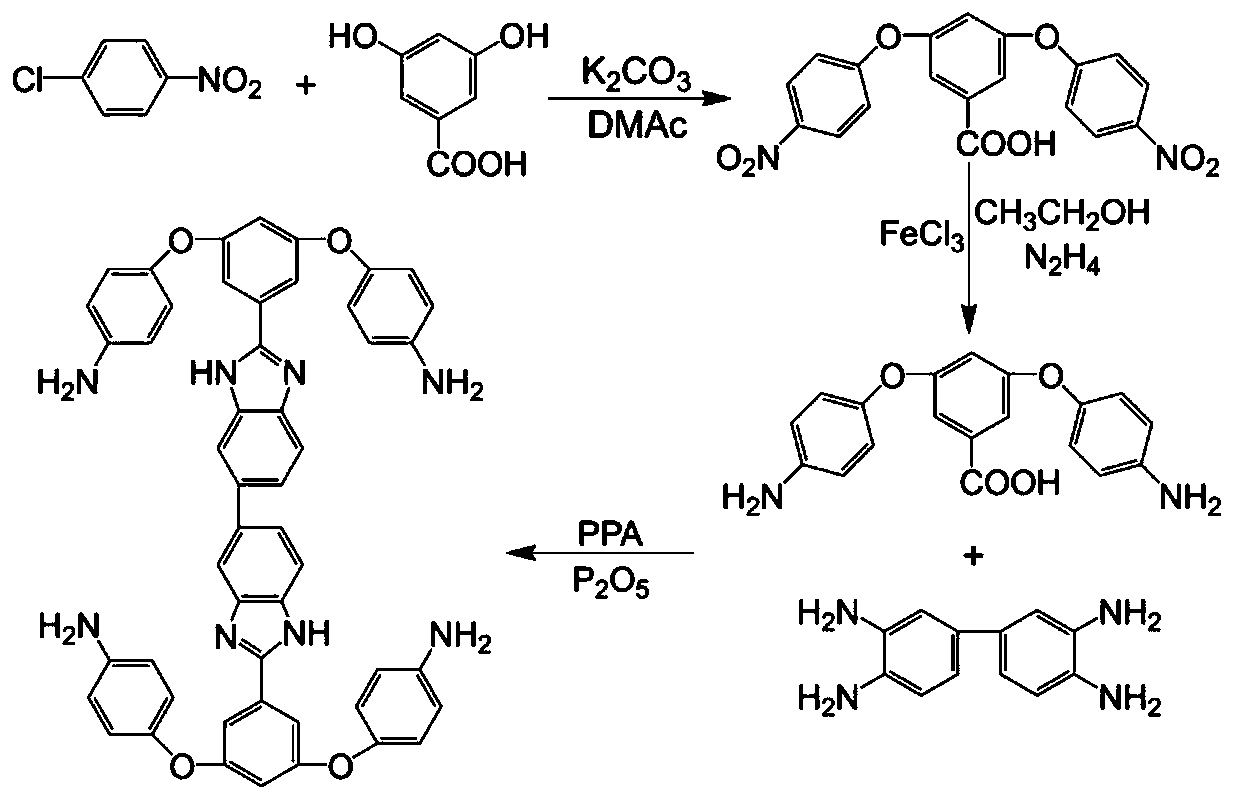

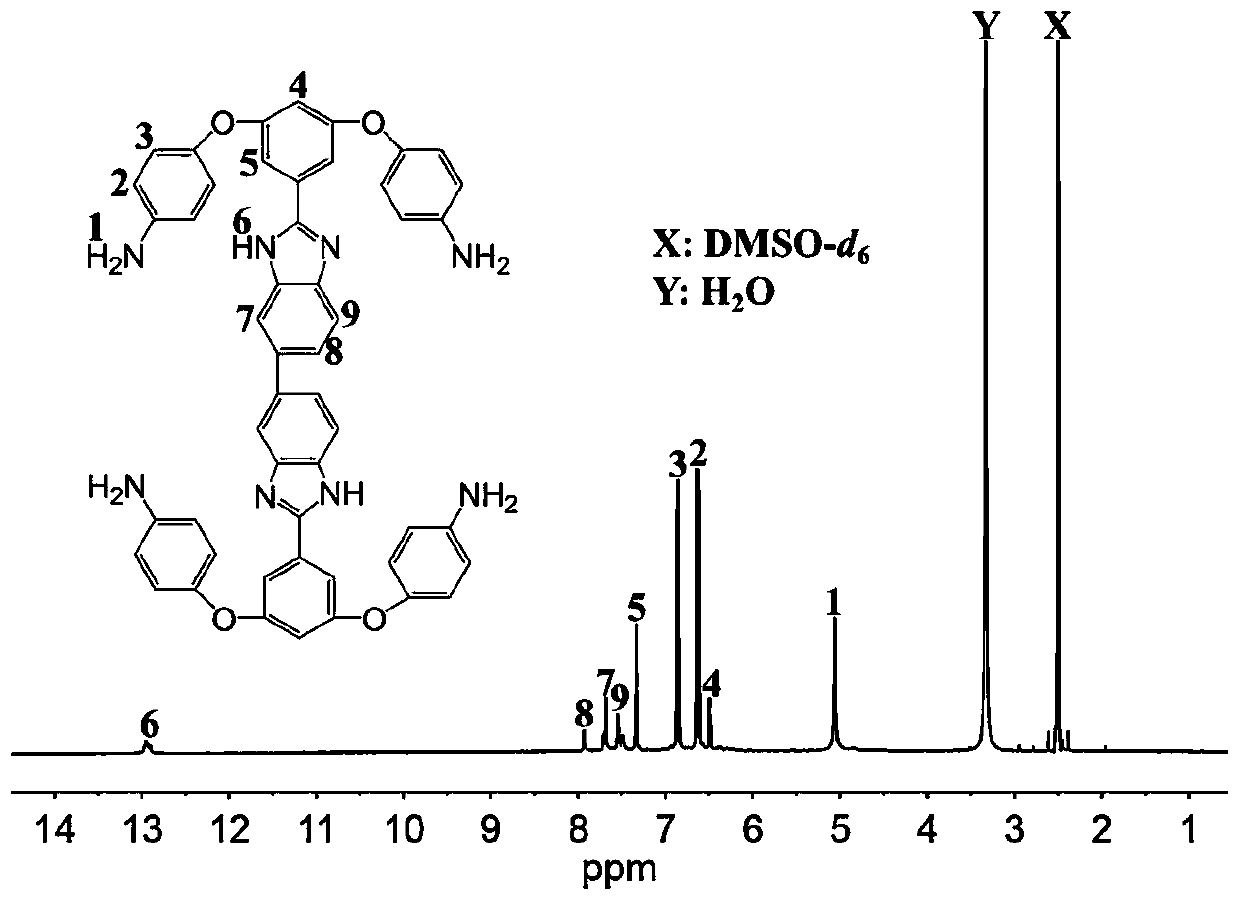

[0035] A preparation method of self-crosslinking sulfonated polyimide membrane, comprising the following steps:

[0036] Step 1. Under the protection of nitrogen, add 8mmol of 1,4,5,8-naphthalene tetracarboxylic dianhydride, 8mmol of benzoic acid, and 40mL of m-cresol into a 250mL three-necked flask in turn, and stir until the solid is completely dissolved; then, add 1.3 mmol 4,4'-diaminodiphenyl ether, 1.3mmol 4,4',4",4"'(5,5'-benzimidazole-2,2')-1,3(phenylene)- Add tetraoxytetraphenylamine, 4mmol 2,2'-disulfonic benzidine, 4mmol triethylamine, and 40mL m-cresol into a 100mL beaker, stir until the solids are completely dissolved; then place the liquid in the beaker under constant pressure drop Slowly add it dropwise into the three-necked flask, and stir the material in the reactor while adding dropwise, and the dropwise time is 10min; the temperature is raised to 60°C, and stirred for 4h; then, the reaction solution is poured on a glass plate, Cast a film, and dry in an oven...

Embodiment 2

[0044] A preparation method of self-crosslinking sulfonated polyimide membrane, comprising the following steps:

[0045] Step 1. Under the protection of nitrogen, add 8mmol of 1,4,5,8-naphthalene tetracarboxylic dianhydride, 8mmol of benzoic acid, and 40mL of m-cresol into a 250mL three-necked flask in sequence, and stir until the solid is completely dissolved; then, add 0.8 mmol 4,4'-diaminodiphenyl ether, 1.6mmol 4,4',4",4"'(5,5'-benzimidazole-2,2')-1,3(phenylene)- Add tetraoxytetraphenylamine, 4mmol 2,2'-disulfonic benzidine, 4mmol triethylamine, and 40mL m-cresol into a 100mL beaker, stir until the solids are completely dissolved; then place the liquid in the beaker under constant pressure drop Slowly add it dropwise into the three-necked flask, and stir the material in the reactor while adding dropwise, and the dropwise time is 10min; the temperature is raised to 60°C, and stirred for 4h; then, the reaction solution is poured on a glass plate, Cast into a film, and dry i...

Embodiment 3

[0053] A preparation method of self-crosslinking sulfonated polyimide membrane, comprising the following steps:

[0054]Step 1. Under the protection of nitrogen, add 8mmol of 1,4,5,8-naphthalene tetracarboxylic dianhydride, 8mmol of benzoic acid, and 40mL of m-cresol into a 250mL three-necked flask in turn, and stir until the solid is completely dissolved; then, add 2.0 mmol 4,4'-diaminodiphenyl ether, 1.0mmol 4,4',4",4"'(5,5'-benzimidazole-2,2')-1,3(phenylene)- Add tetraoxytetraphenylamine, 4mmol 2,2'-disulfonic benzidine, 4mmol triethylamine, and 40mL m-cresol into a 100mL beaker, stir until the solids are completely dissolved; then place the liquid in the beaker under constant pressure drop Slowly add it dropwise into the three-necked flask, and stir the material in the reactor while adding dropwise, and the dropwise time is 10min; the temperature is raised to 60°C, and stirred for 4h; then, the reaction solution is poured on a glass plate, Cast into a film, and dry in an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com