Scale inhibitor for raw materials of hydrogenation device and preparation method thereof

A technology of hydrogenation unit and scale inhibitor, which is applied in the fields of processing equipment corrosion/fouling inhibition, petroleum industry, processing hydrocarbon oil, etc., can solve problems such as no effective solution, and achieves reduction of energy loss, simple and easy-to-control process, and high exchange rate. The effect of thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

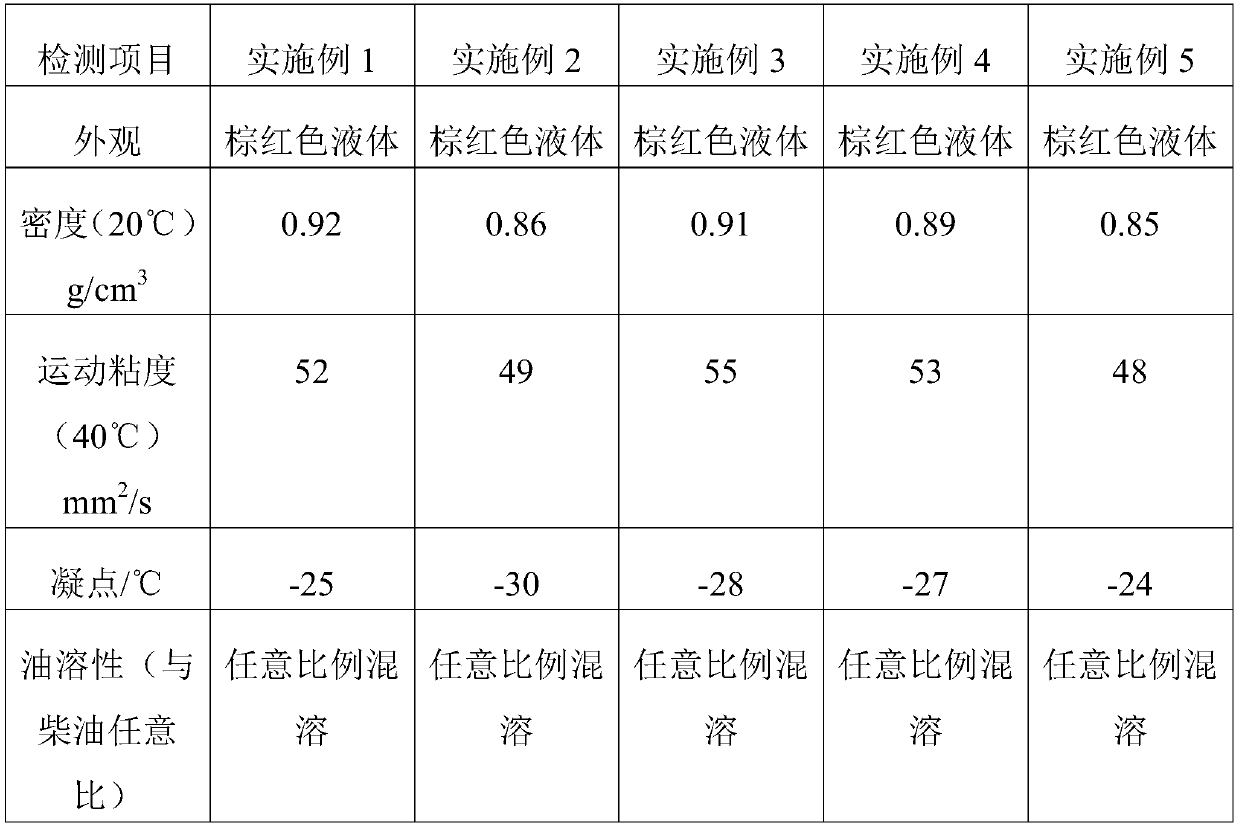

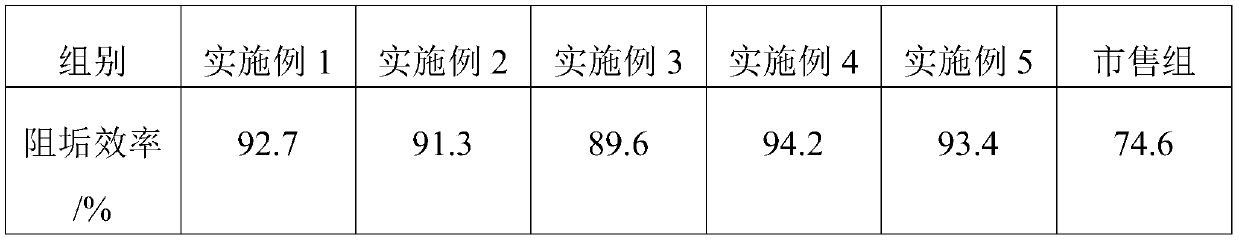

Embodiment 1

[0027] This embodiment provides a preparation method of a scale inhibitor for hydrogenation unit raw materials:

[0028] 8kg N-cyclohexylthiophthalamide, 10kg 2-tert-butyl hydroquinone, 25kg polyalkenyl succinimide, 6kg oleylamine ethyl imidazoline, 10kg monoethanolamine and 41kg 200 # Stir the solvent oil for 30 minutes under the condition of 60r / min to obtain the scale inhibitor for the raw material of the hydrogenation unit.

Embodiment 2

[0030] This embodiment provides a preparation method of a scale inhibitor for hydrogenation unit raw materials:

[0031] 13kg of benzoic acid, 15kg of 4-hydroxy-2,2,6,6-tetramethylpyridine-1-oxyl radical, 30kg of bis-polyisobutylene succinimide, 12kg of trans-oleylamine ethyl imidazoline , 15kg of crude white oil and 15kg of 200# solvent oil were stirred for 40min under the condition of 80r / min to obtain the scale inhibitor of the raw material of the hydrogenation unit.

Embodiment 3

[0033] This embodiment provides a preparation method of a scale inhibitor for hydrogenation unit raw materials:

[0034] The composition of 10.5kg N-nitrosodiphenylamine, 12.5kg 2-tert-butyl hydroquinone and 4-hydroxyl-2,2,6,6-tetramethylpyridine-1-oxyl free radical, 27.5 The composition of kg polyisobutylene succinimide, 9kg cis oleic acid base amine ethyl imidazoline, 12.5kg monoethanolamine and crude white oil, 28kg 200# solvent oil stirred 35min under the condition of 70r / min, namely The antiscalant for hydrogenation unit raw materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com