Integrated polarization beam splitter based on thin-film lithium niobate waveguide

A polarizing beam splitter, lithium niobate technology, applied in the directions of light guides, instruments, optics, etc., can solve the problems of increasing the design difficulty of asymmetric couplers, and achieve the effects of simple structure, low loss and large processing tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

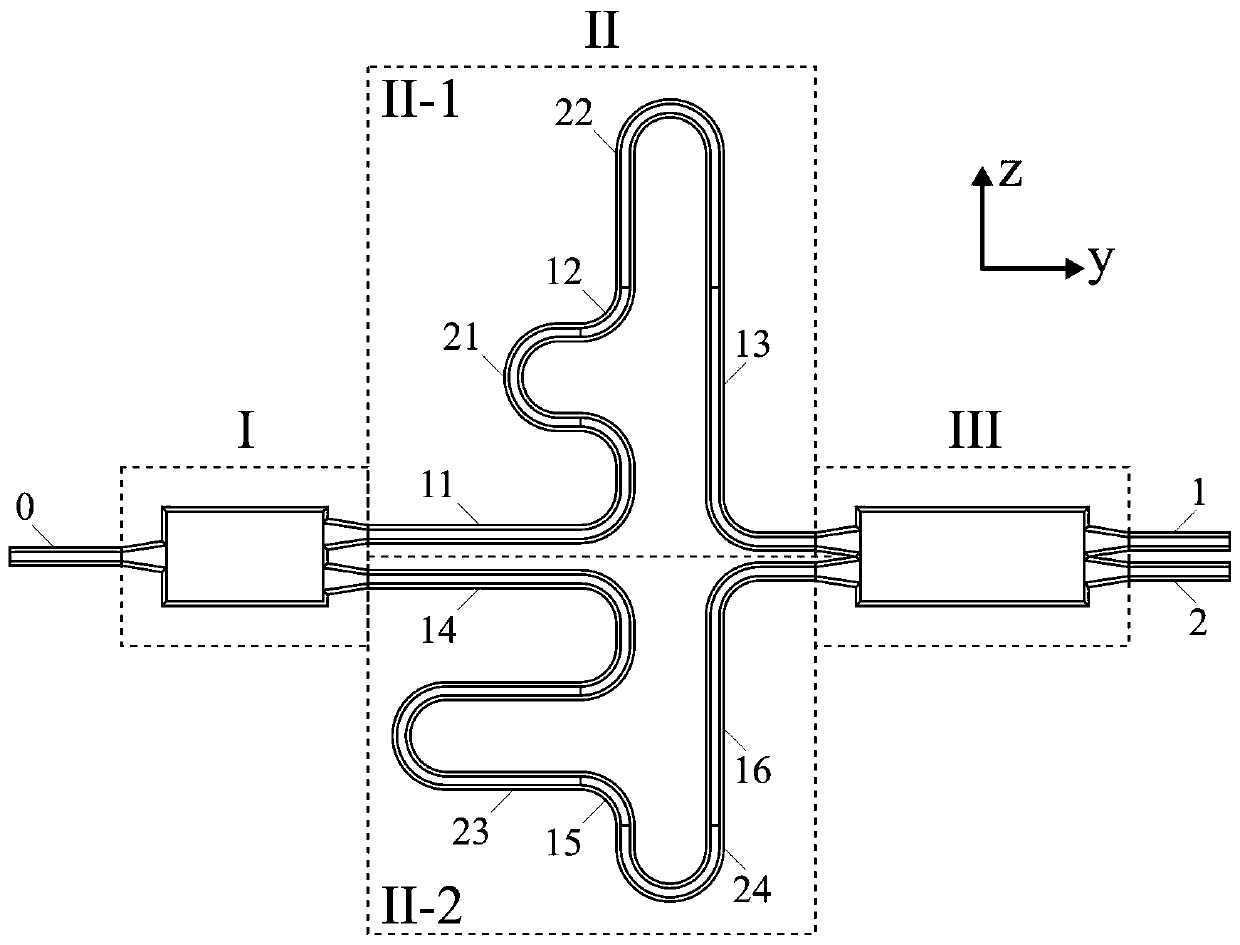

[0020] The present invention will be further described below with reference to the accompanying drawings and the implementation examples of the integrated polarization beam splitter based on thin-film lithium niobate waveguide.

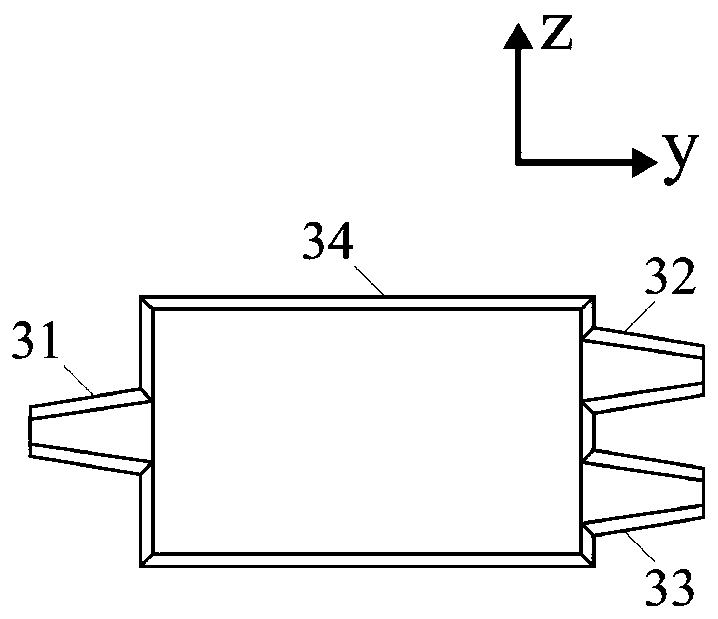

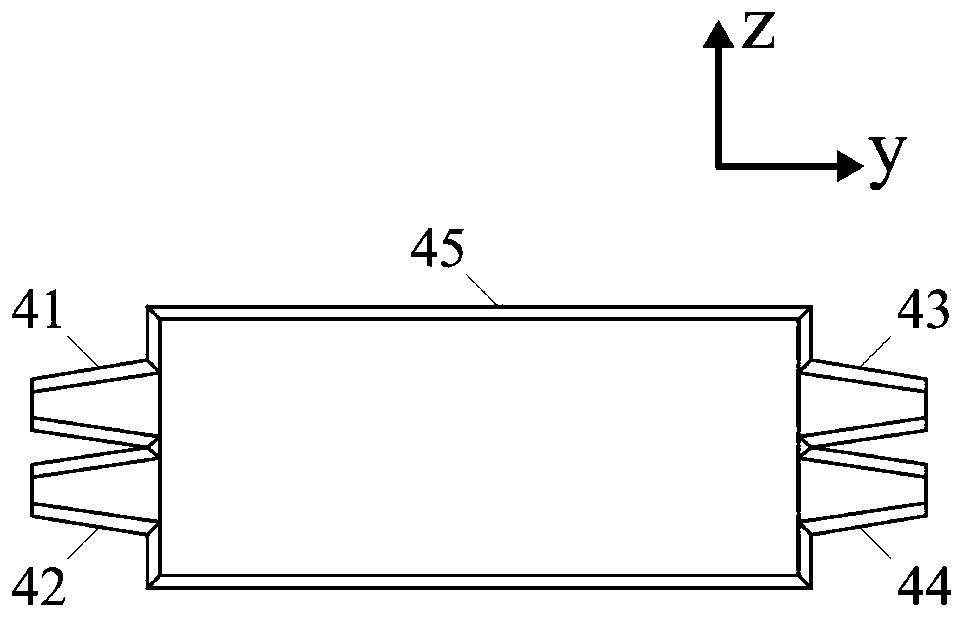

[0021] A thin-film lithium niobate waveguide based on Lithium-Niobate On Insulator (LNOI) material is selected, its core layer is lithium niobate material with a thickness of 700nm; its substrate layer is made of silicon dioxide material with a thickness of 2μm; The upper cladding layer is made of silicon dioxide material with a thickness of 2 μm. In this embodiment, the inclination angle of the sidewall of all waveguide structures is 70°, and the width of all single-mode thin-film lithium niobate waveguides in the multi-stage phase shifter (II) is 300 nm.

[0022] The transmission directions of the input waveguide (0), the first output waveguide (1) and the second output waveguide (2) are all in the y direction. Both the first phase-shift waveguide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com