A kind of preparation method of high corrosion resistance sintered NdFeB magnet

A high corrosion resistance, NdFeB technology, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems that corrosion resistance cannot be improved, material corrosion resistance is poor, and it is difficult to obtain guarantees. Achieve the effects of reducing oxygen supplementation of fine powder, improving temperature stability and corrosion resistance, and boundary stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

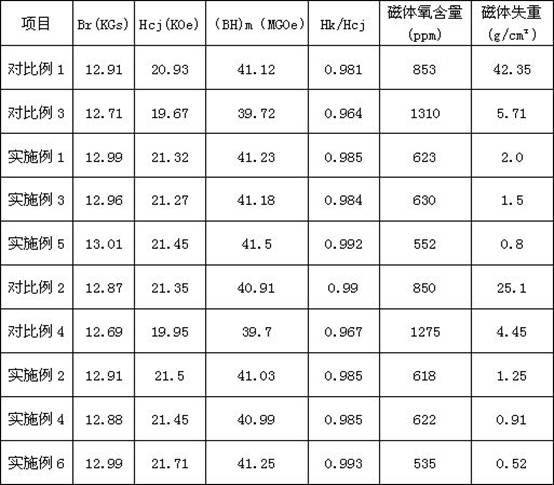

Examples

Embodiment 1

[0041] The Nd-Fe-B alloy cast sheet prepared in Comparative Example 1 was placed in dry air and exposed for 15 days, after the Nd-rich phase of the alloy cast sheet fully absorbed oxygen. Cast the alloy after the neodymium-rich phase has fully absorbed oxygen, and carry out hydrogen crushing. The hydrogen crushing process takes 3 hours, and then dehydrogenates and cools to obtain coarse powder. Add 0.1% YSH6 high-molecular polymer lubricant and 0.1% YSH1 low-molecular polymer antioxidant to the coarse powder for homogenization and stirring. The powder is subjected to jet milling without supplementing oxygen to obtain a fine powder with a particle size of 2.4-8.5um; the fine powder is oriented and molded under a magnetic field strength above 18000Gs, and the oxygen content in the press is controlled at Below 10ppm, a green body is obtained. The magnet green body is subjected to cold isostatic pressing, and the isostatic pressure is 200 MPa; the green body is sintered, aged, an...

Embodiment 2

[0043] The Nd-Fe-B alloy cast sheet prepared in Comparative Example 2 was placed in dry air and exposed for 15 days, after the Nd-rich phase of the alloy cast sheet fully absorbed oxygen. Cast the alloy after the neodymium-rich phase has fully absorbed oxygen, and carry out hydrogen crushing. The hydrogen crushing process takes 3 hours, and then dehydrogenates and cools to obtain coarse powder. Add 0.1% YSH6 high-molecular polymer lubricant and 0.1% YSH1 low-molecular polymer antioxidant to the coarse powder for homogenization and stirring. The powder is subjected to jet milling without supplementing oxygen to obtain a fine powder with a particle size of 2.4-8.5um; the fine powder is oriented and molded under a magnetic field strength above 18000Gs, and the oxygen content in the press is controlled at Below 10ppm, a green body is obtained. The magnet green body is subjected to cold isostatic pressing, and the isostatic pressure is 200 MPa; the green body is sintered, aged, an...

Embodiment 3

[0045] The Nd-Fe-B alloy cast sheet prepared in Comparative Example 1 was placed in dry air and exposed for 15 days, after the Nd-rich phase of the alloy cast sheet fully absorbed oxygen. Cast the alloy sheet after the neodymium-rich phase has fully absorbed oxygen, and carry out hydrogen crushing. The hydrogen crushing process takes 3 hours. Introduce 50ppm of pure oxygen into the device, let the coarse powder absorb oxygen, the oxygen content will be below 10ppm, if there is no drop within 10 minutes, cool it down to get coarse powder. Add 0.1% YSH6 high-molecular polymer lubricant and 0.1% YSH1 low-molecular polymer antioxidant to the coarse powder for homogenization and stirring. The powder is subjected to jet milling without supplementing oxygen to obtain a fine powder with a particle size of 2.4-8.5um; the fine powder is oriented and molded under a magnetic field strength above 18000Gs, and the oxygen content in the press is controlled at Below 10ppm, a green body is ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com