Lithium metal negative electrode, preparation method and lithium ion battery

A lithium metal negative electrode, lithium metal technology, applied in the field of lithium metal negative electrode, can solve the problems of reducing battery energy density, unsatisfactory lithium deposition morphology, improving energy density, etc., so as to suppress the formation of lithium dendrites and reduce local current density. , the effect of low overpotential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

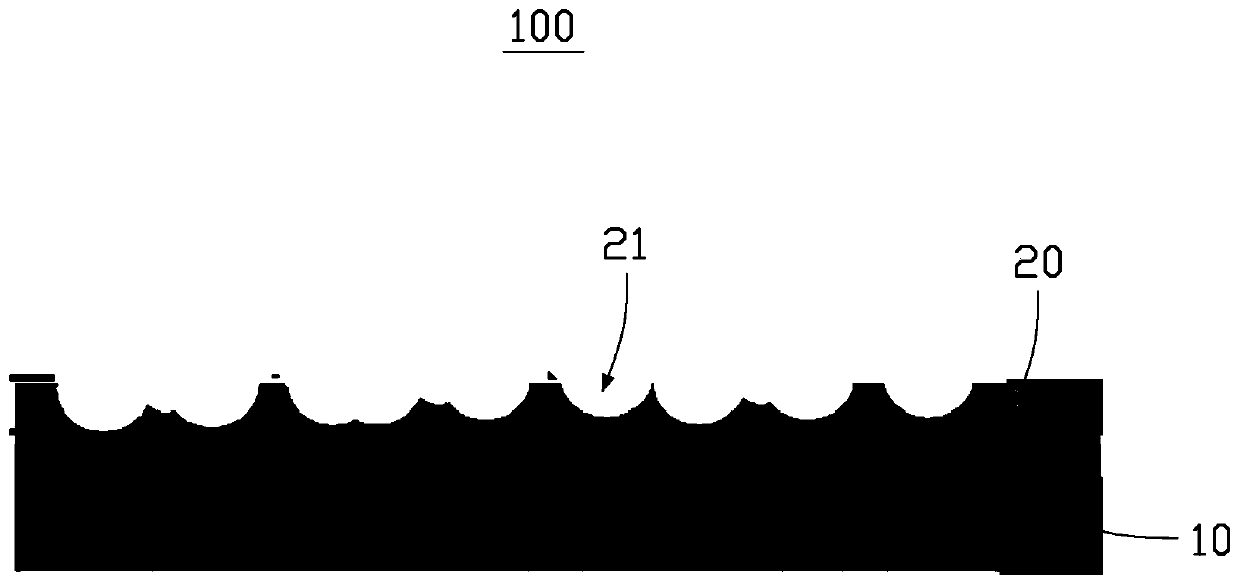

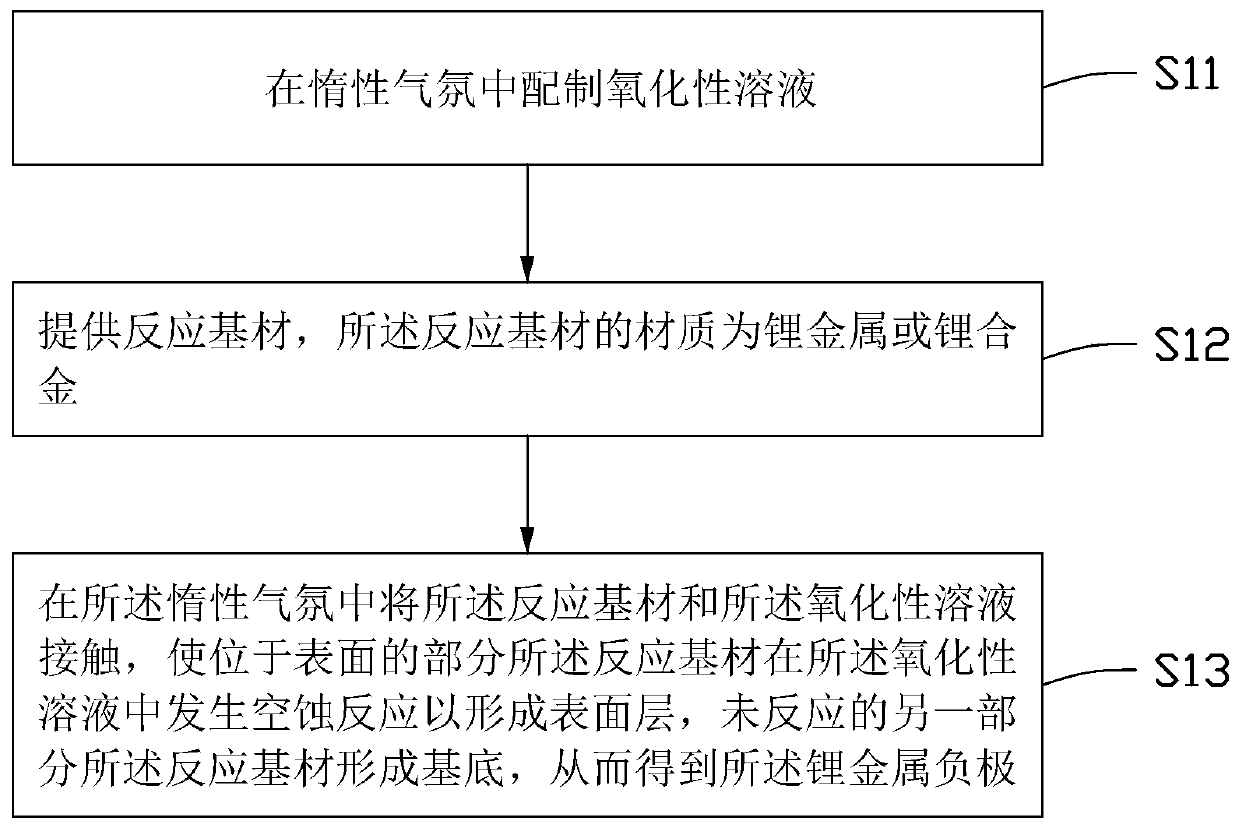

[0032] see image 3 , a preferred embodiment of the present invention also provides a method for preparing the lithium metal negative electrode 100, comprising the following steps:

[0033] Step S11, preparing an oxidizing solution in an inert atmosphere.

[0034] Wherein, the oxidizing solution includes an oxidizing agent and an organic solvent. Wherein, the oxidant has an oxidation effect on lithium metal; the organic solvent has good solubility to the oxidant, is stable to the lithium metal, and does not cause side reactions with the lithium metal. Preparation of the oxidizing solution in an inert atmosphere prevents reduction of the oxidizing agent.

[0035] In this embodiment, the oxidizing agent includes at least one of iodine, bromine and chlorine. The concentration of the oxidizing agent is 1-50mg mL -1 . Preferably, the concentration of the oxidizing agent is 10-30mg mL -1 . The organic solvent includes at least one of tetrahydrofuran, carbon disulfide, N-methy...

Embodiment 1

[0047] The first step is to prepare 5mL concentration of 15mg mL in an argon protection glove box -1 solution of iodine in tetrahydrofuran and store it in a glass bottle. Wherein, in the argon protective atmosphere, the molar fractions of oxygen and water vapor are respectively lower than 5 ppm and 1 ppm.

[0048] In the second step, the lithium metal sheet is soaked in the tetrahydrofuran solution of iodine, and the glass bottle is sealed with a parafilm.

[0049]In the third step, the packaged glass bottle is transferred to the air, and the glass bottle is placed in an ultrasonic device for ultrasonic treatment. The ultrasonic frequency is set to 20kHZ, the ultrasonic temperature is 30°C, and the ultrasonic time is 300s.

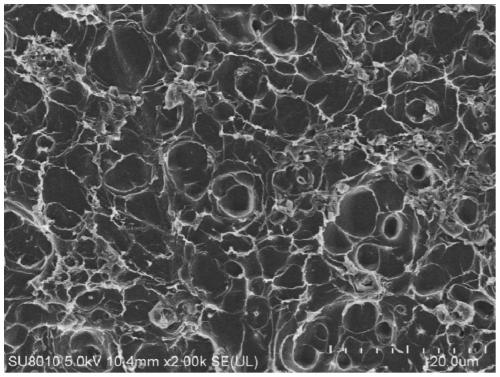

[0050] The fourth step is to transfer the glass bottle to the argon protection glove box, take out the lithium metal sheet after ultrasonic treatment, and clean the treated lithium metal sheet with tetrahydrofuran cleaning agent, so as to obtain the Lith...

Embodiment 2

[0052] This embodiment is with respect to embodiment 1, and difference is: in the first step, the concentration of iodine is 30mgmL -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com