Shrimp culture farm

A technology for farms and shrimps, which is applied in the field of shrimp farms, can solve the problems of ineffective use of farm space, inability to recycle tail water in breeding ponds, and low output of shrimp farming, so as to reduce sewage discharge and reduce water consumption. The effect of resource usage and convenient transshipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

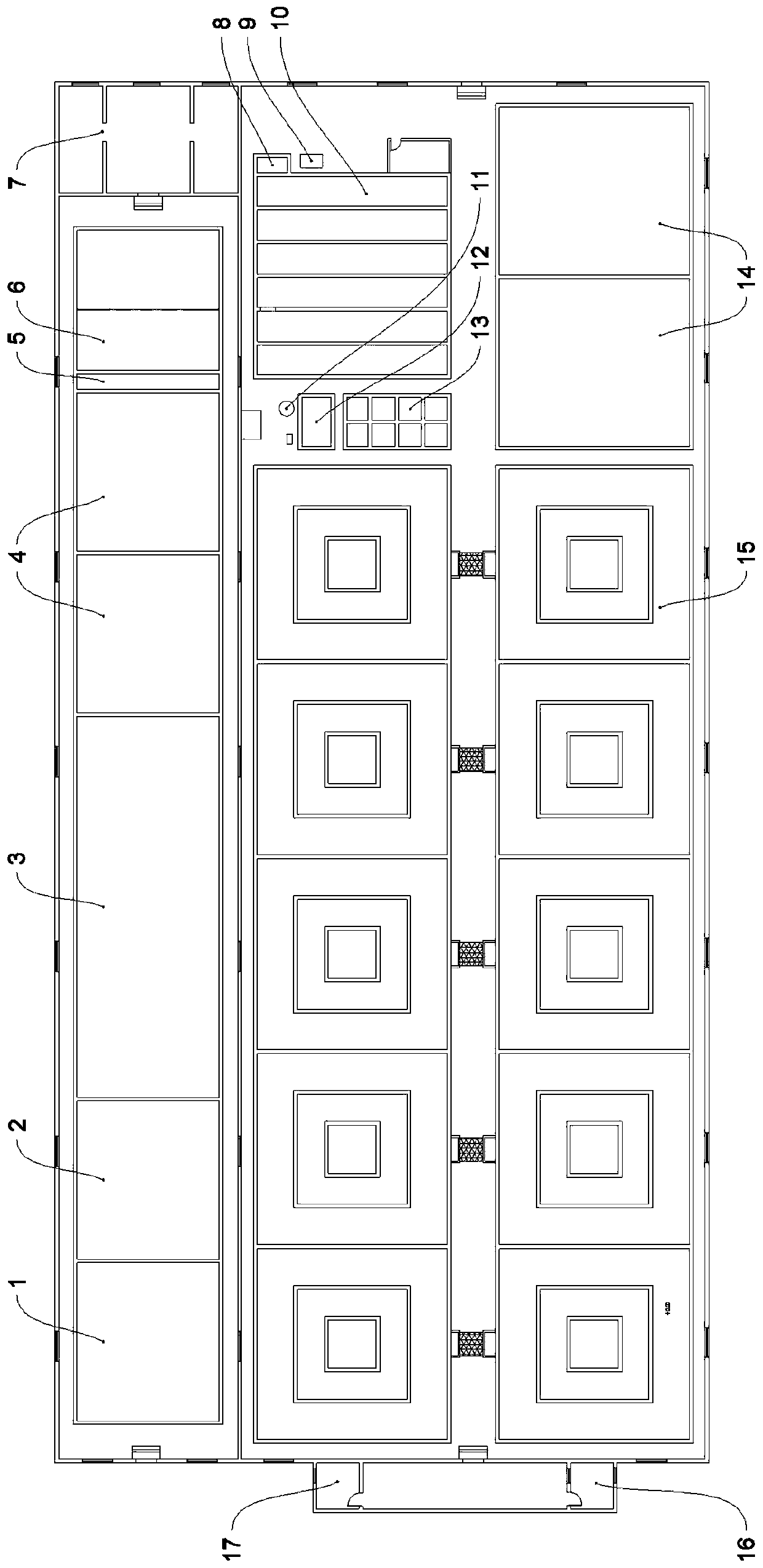

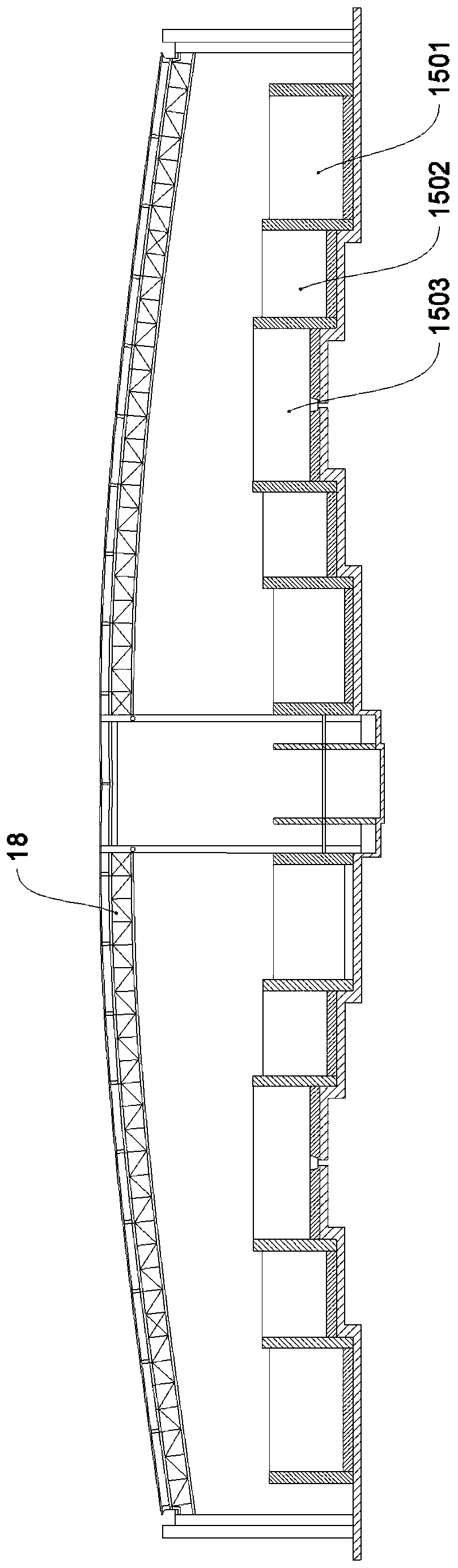

[0031] see Figure 1~6 , a kind of shrimp breeding farm, comprises field and the greenhouse 18 structures that will cover the field, is provided with cultivation module, new water treatment module, tail water treatment module and water purification module on the field; Culture module is made up of a plurality of multistage cultivation ponds 15 The new water treatment module is used to treat the new water introduced from the outside, the tail water treatment module is used to treat the tail water discharged from the aquaculture module, and the water purification module can process the tail water treatment module and the new water treatment module. The water is purified and used for the breeding module.

[0032] In this embodiment, the structure of the greenhouse 18 makes the farm an indoor structure. Compared with open-air breeding, indoor breeding is not affected by factors such as region, environment, and climate, and has strong environmental adaptability. The cultivation mo...

Embodiment 2

[0034] see Figure 1~6 , this embodiment is further optimized on the basis of embodiment 1, specifically:

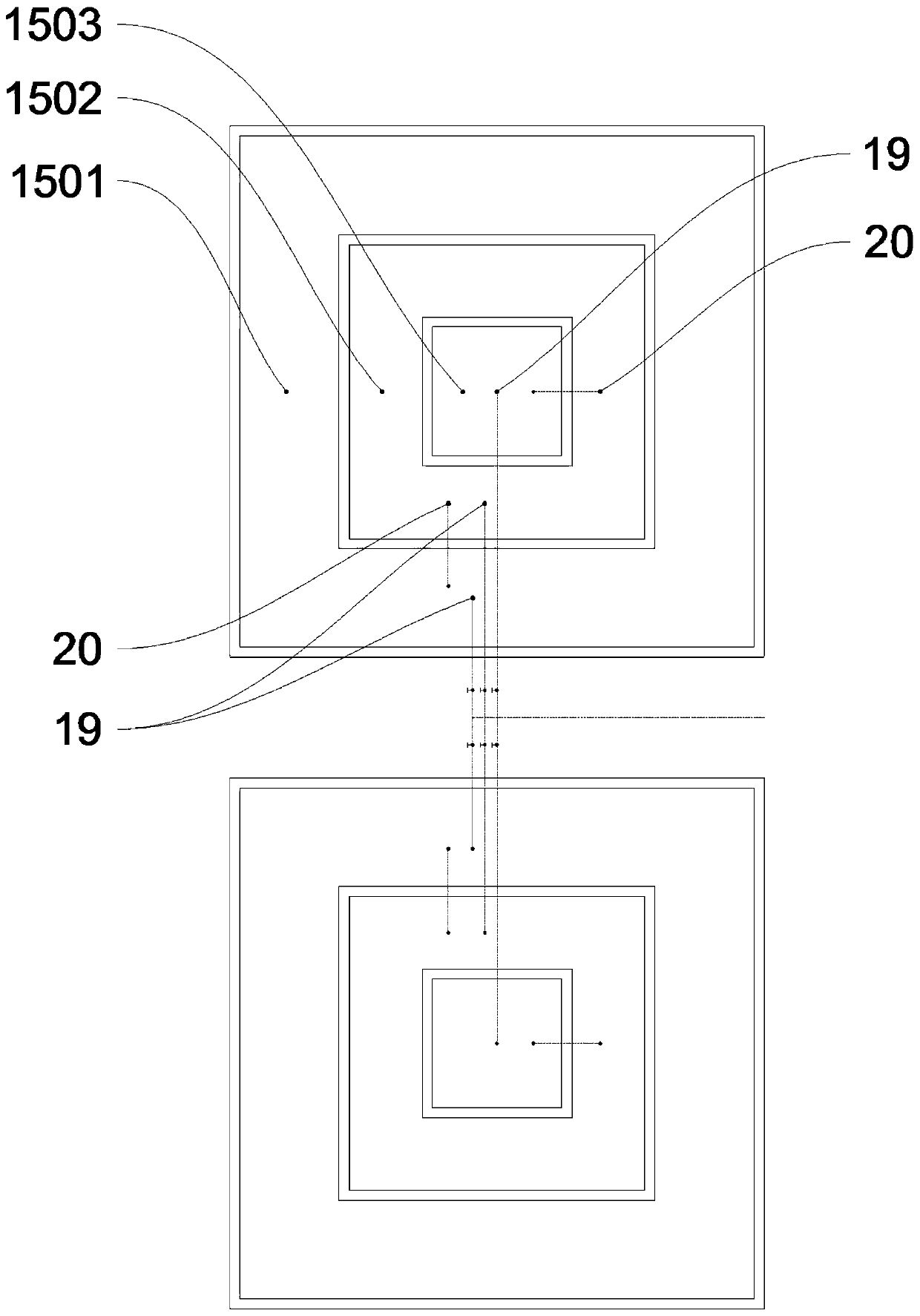

[0035] Multi-level cultivation pool 15 comprises the first-level cultivation pond 1503, the second-level cultivation pond 1502 and the third-level cultivation pond 1501 connected inside and outside, and the cultivation area of the first-level cultivation pond 1503, the second-level cultivation pond 1502 and the third-level cultivation pond 1501 increases successively. Large; the first-level culture pond 1503, the second-level culture pond 1502 and the third-level culture pond 1501 are all provided with an openable and closable outfall 19, and the outfall 19 is provided with an escape-proof net or an escape-proof grid.

[0036]In this embodiment, the three-level structure of the multi-level culture pond 15 can carry out graded cultivation of shrimps in different growth periods. Taking Penaeus vannamei, one of the three largest shrimp species with the highest cultivation...

Embodiment 3

[0049] see Figure 1~6 , this embodiment is further optimized on the basis of embodiment 1, specifically:

[0050] The new water treatment module includes a fresh water pool 1 and a blending pool 2. After being treated by the fresh water pool 1 and the blending pool 2, the new water is discharged into the first storage pool 3 for storage and ready for use.

[0051] Among them, the new water is introduced into the fresh water pool 1 through the external pipeline, and after the sediment in the water is sedimented in the fresh water pool 1, it is then introduced into the blending pool 2 for blending, and after the blending is completed, it is transferred to the first reservoir 3 Store for later use.

[0052] The blending pool 2 is used to add salt to adjust the fresh water to a salinity suitable for shrimp farming. Taking Penaeus vannamei as an example, the adaptable salinity for its growth is 2-34‰, and the optimum growth salinity is 10-20‰. Similar to Chinese prawns. In the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com