Synthesis device, application thereof and method for producing thermotropic liquid crystal polymer

A synthesis device and liquid storage tank technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems affecting the final performance of liquid crystal polymers, affecting the precise molar ratio, etc., to achieve compact structure, gentle and controllable reaction , the effect of inhibiting the precipitation of monomers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

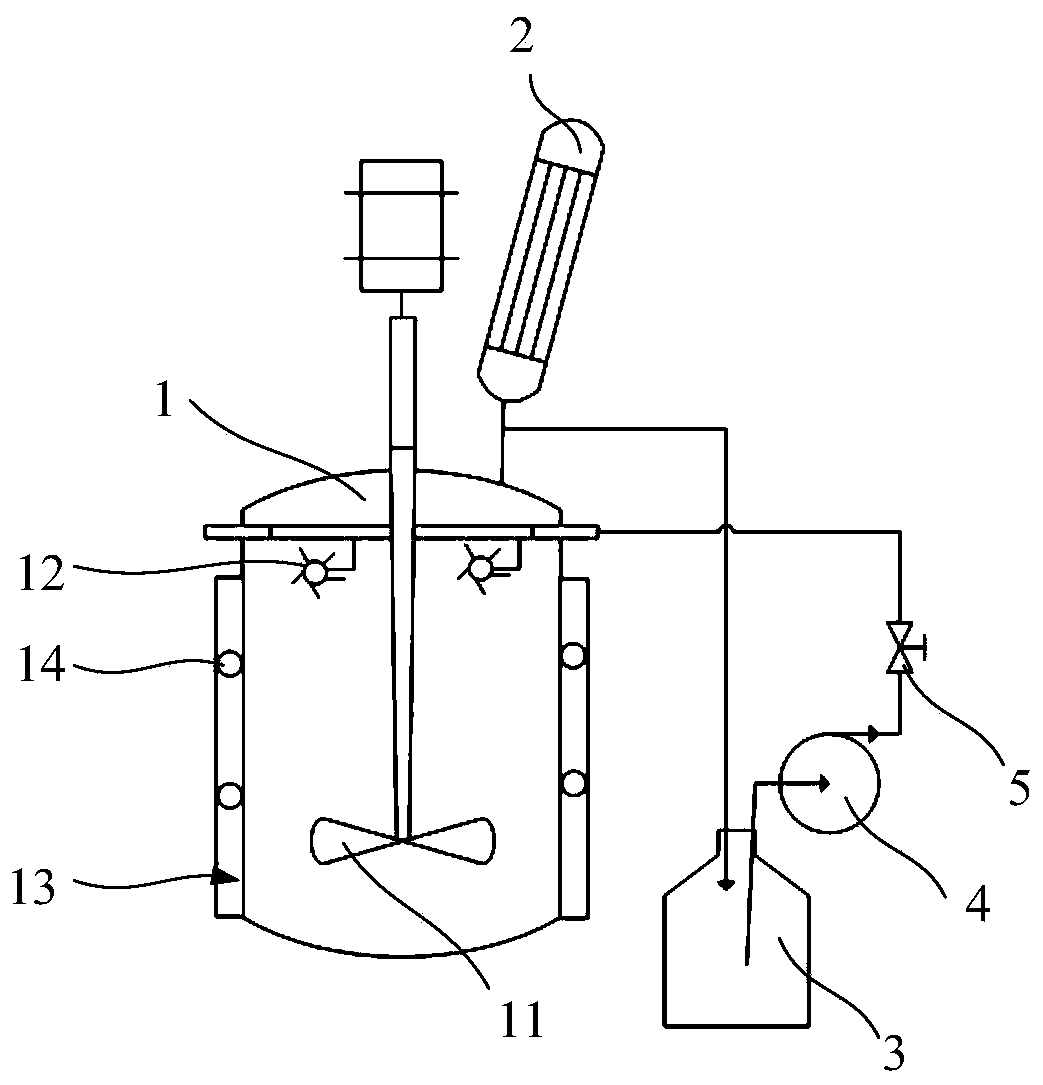

[0033] Such as figure 1 As shown, a synthesis device for liquid crystal polyester is provided in the embodiment of the present application, and the synthesis device includes a reaction kettle 1, a condenser 2 and a liquid storage tank 3;

[0034] The reaction kettle 1 is communicated with the liquid inlet of the condenser 2 through a first pipeline;

[0035] The liquid storage tank 3 communicates with the liquid outlet of the condenser 2 through a second pipeline;

[0036] The reactor 1 is provided with an agitator 11, a shower 12 and a temperature sensor; the liquid storage tank 3 communicates with the shower 12 through a third pipeline;

[0037] The third pipeline is provided with a metering pump 4 and a first temperature control switch 5; the first temperature control switch 5 is electrically connected to the temperature sensor.

[0038] In the present application, the reaction material of the reaction device is heated to a certain temperature in the reactor to maintain a...

Embodiment 2

[0061] Add p-hydroxybenzoic acid 1657.4g, 2-hydroxyl-6-naphthoic acid 752.72g, hydroquinone 220.2g, terephthalic acid 332.2g, potassium acetate 8.4g (polymerization catalyst) and p-toluenesulfonic acid in reactor Acid 11g (acetylation reaction catalyst), acetic anhydride 2500g.

[0062] After the reactants were mixed and stirred evenly, the acetylation reaction was carried out under nitrogen atmosphere at 155° C. under reflux for 2.5 h. When the monomer sublimates and precipitates on the wall of the kettle, the cooling water is opened in the cooling unit to cool down in the oil bath, and at the same time, the sprayer sprays the solvent to wash the monomer back into the reactor to continue the reaction. Subsequently, the temperature was further raised to 350°C within 5 hours, during which the reaction temperature rise rate was controlled by the cooling water flux in the cooling pipe and the shower, so that the polymerization reaction proceeded gradually and gently. As acetic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com