Industrial wastewater treatment system based on low-temperature mass transfer concentration technology

A technology for treating system and industrial wastewater, applied in the direction of heating water/sewage treatment, etc., can solve the problems of unstable treatment effect, high economic cost, and small treatment range of wastewater treatment technology, and achieve high energy utilization efficiency and no secondary pollution. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

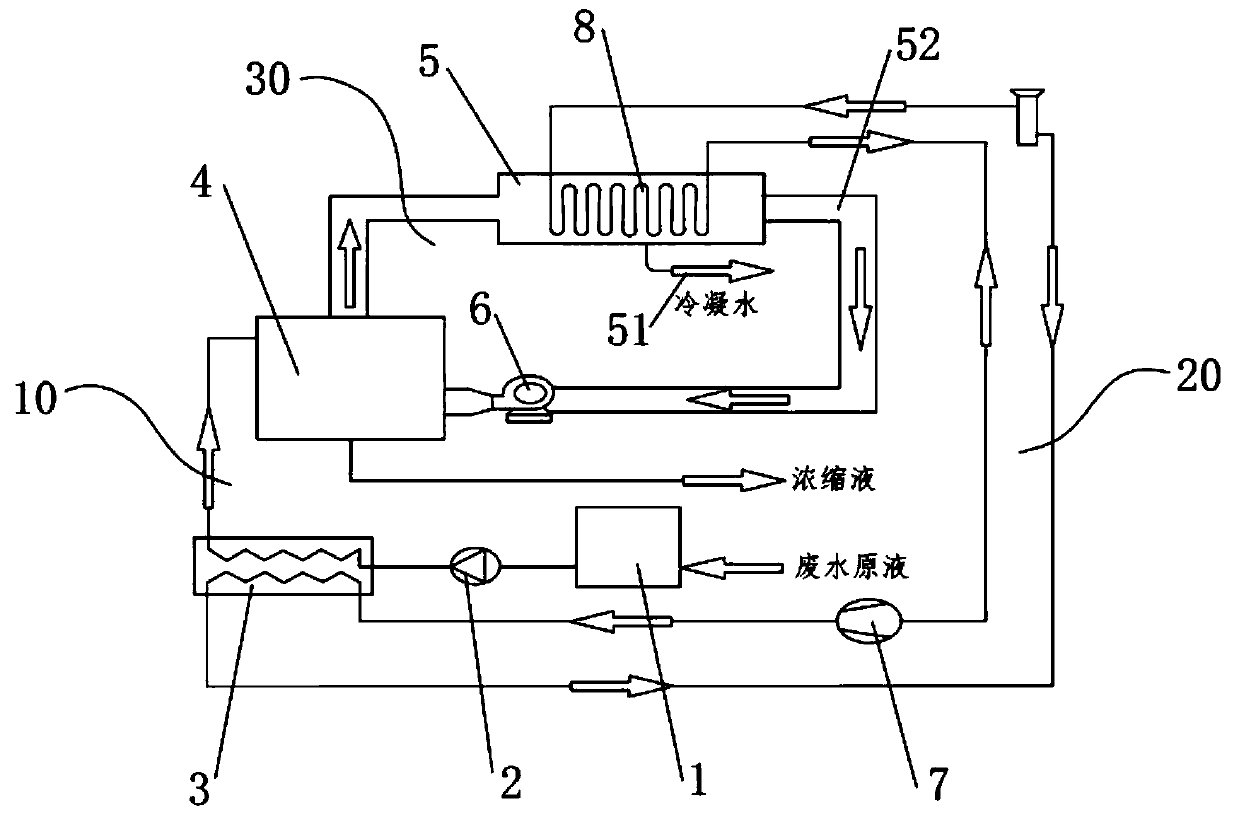

[0019] Please refer to figure 1 , the present invention provides an industrial wastewater treatment system based on low-temperature mass transfer concentration technology, including a solution tank 1, a water pump 2, a condenser 3, a mass transfer unit 4, a moisture analysis unit 5, a fan 6 and a compressor 7; the solution tank 1 is used to contain the waste water stock solution, the outlet of the solution tank 1 is connected to the water pump 2, the outlet of the water pump 2 is connected to the condenser 3, the condenser 3 is connected to the mass transfer unit 4, and the outlet of the mass transfer unit 4 is connected to the moisture analysis unit 5 The moisture analysis unit 5 includes a condensed water outlet 51 and a circulating air outlet 52. The circulating ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com