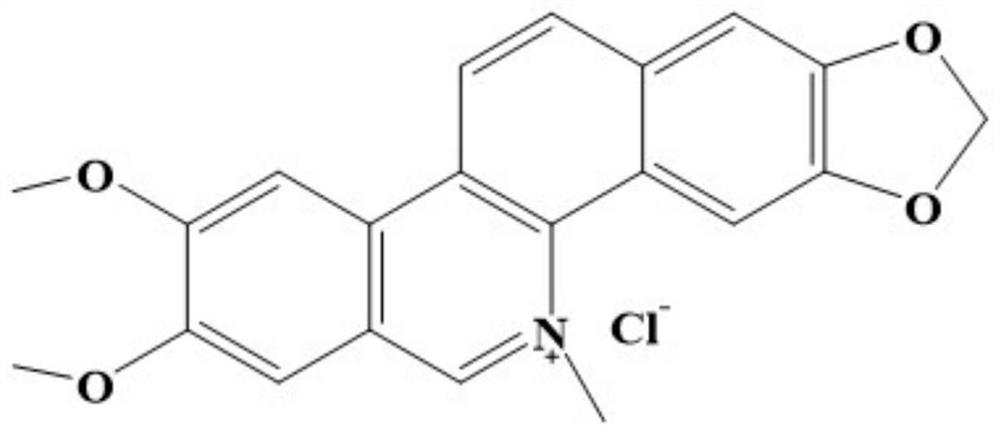

Application of a kind of nano-carrier mil-100(fe) on the loading of acanthine chloride

A technology of chlorinated syringamine and nano-carrier, applied in the field of nano-carrier research, can solve the problem of not finding liver toxicity, and achieve the effects of saving experimental raw materials and costs, reducing toxicity, and being easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of preparation method of nanocarrier MIL-100 (Fe), is to ferric nitrate, H 3 BTC, H 2 O, HNO 3 According to the molar ratio of 1:0.66:208:2, mix and place in an autoclave, heat and react at 100°C for 12 hours, filter and separate after the reaction, wash the filtered powder, and dry it in a vacuum at 100°C overnight. The nanocarrier MIL-100(Fe) is obtained; the washing method is: disperse the powder in hot water at 60°C for 3 hours according to the solid-to-liquid ratio of 1g:500mL, and then disperse the powder at 60°C according to the solid-to-liquid ratio of 1g:100mL ℃ dispersed in ethanol for 3h.

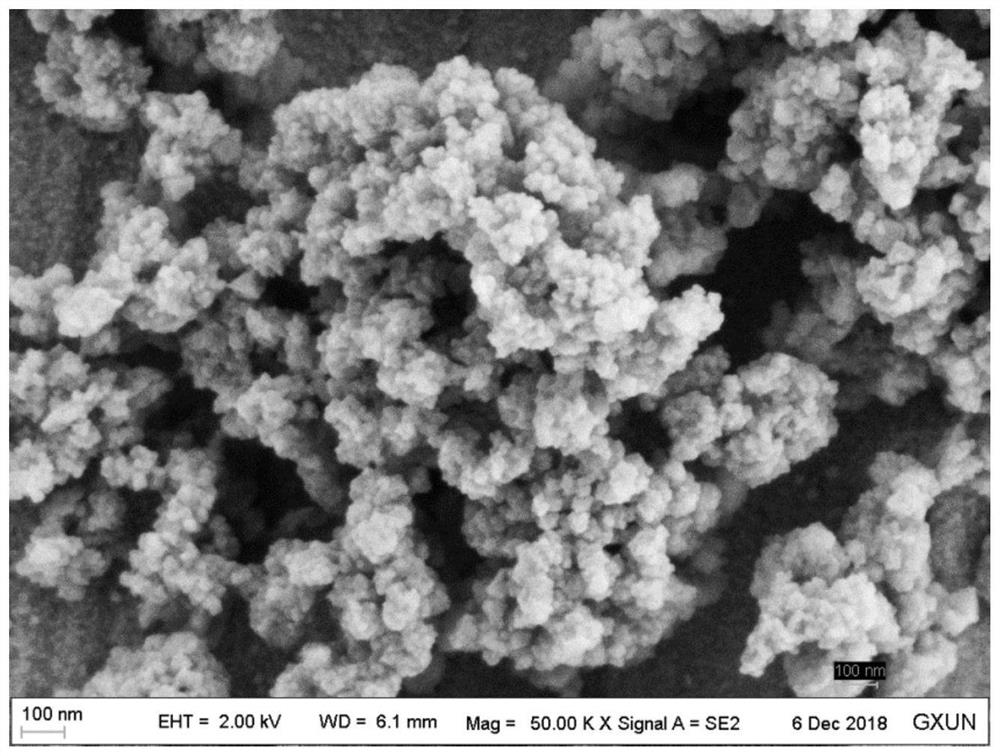

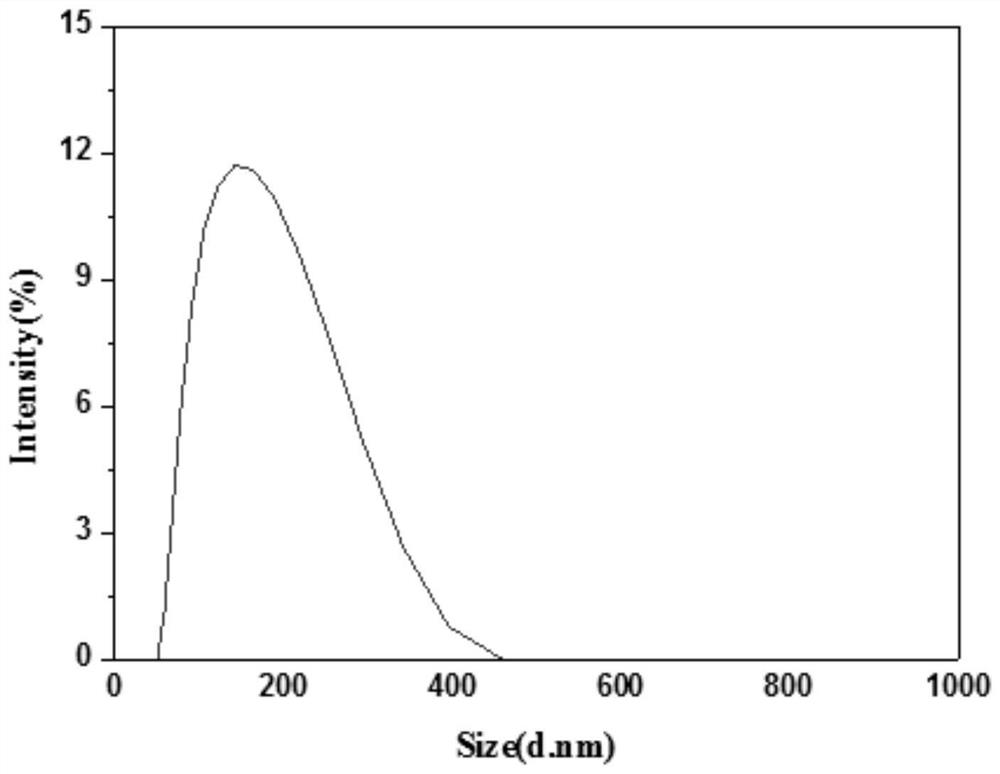

[0037] The obtained nano-carrier MIL-100 (Fe) is subjected to electron microscope scanning detection, and the obtained SEM image is as follows: figure 2 Shown; Use the particle size distribution of further characterizing MIL-100 (Fe) of nano particle size analyzer DLS, the particle size distribution figure that obtains is as image 3 shown.

[0038] figure 2 f...

Embodiment 2

[0040] The nano-carrier MIL-100 (Fe) prepared in Example 1 is applied to load acanthine chloride:

[0041] Specifically, the MIL-100(Fe) was put into methanol and acanthine chloride, stirred at room temperature for 5 days, and then centrifuged at room temperature at 1000rpm for 15 minutes to obtain loaded particles, denoted as NC@MIL-100;

[0042] Wherein, the consumption of described, methyl alcohol, dihedral chloride is as shown in table 1. The load rate after testing is shown in Table 1.

[0043]

[0044] Table 1

[0045] serial number MIL-100(Fe) / mg Methanol / ml NC / mg Load rate (w%) 1 1 10 1 11.63±1.31 2 1 10 2 23.23±2.35 3 1 10 3 33.43±1.14 4 1 10 4 33.53±2.15 5 1 10 5 33.8±0.98

Embodiment 3

[0047] In order to evaluate the crystal structures of MIL-100(Fe) obtained in Example 1 and NC@MIL-100 obtained in Example 2, XRD analysis was performed on them, and a simulated group of MIL-100(Fe) was added for comparison.

[0048] Figure 4 It is the XRD pattern of MIL-100(Fe), NC@MIL-100. Compared with the spectrum of the simulated group, the MIL-100 (Fe) obtained in Example 1 has a better matching degree with its diffraction peaks, indicating that the synthesis of MIL-100 (Fe) crystals is successful; the NC@MIL-100 obtained in Example 2 The XRD profile exhibited can be similar to that of MIL-100(Fe), implying that its crystalline structure is maintained after drug encapsulation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com