Preparation method of anti-fog coating

An anti-fog coating and coating technology, applied in coatings, climate change adaptation, etc., can solve the problems of complex experimental process and conditions, inconvenient practicability, and small application range, and achieve simple, fast and mild process of preparation The effect of environmental protection and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

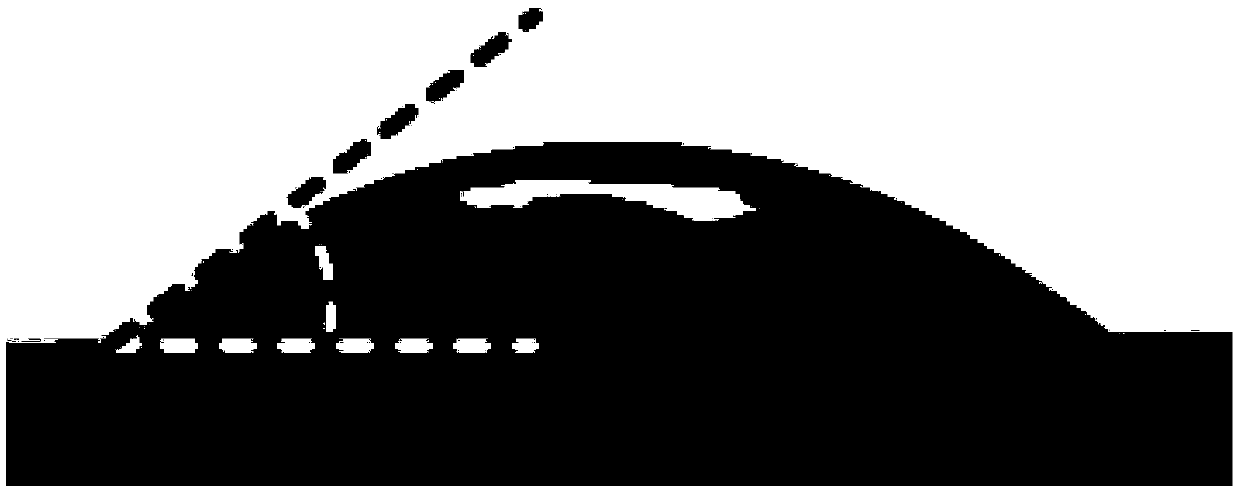

Image

Examples

Embodiment 1

[0020] Embodiment 1: a kind of preparation method of anti-fog coating, the conditions and steps of preparation are as follows:

[0021] (1) Treatment of hydrophobic material substrates

[0022] The selected hydrophobic material substrate is a low-density polyethylene (LLDPE) film. At room temperature, wipe the surface of the LLDPE film with deionized water and absolute ethanol to remove various impurities on the surface of the substrate, and dry it at room temperature. The volume concentration of the described absolute ethanol is 99.8%, and the deionized water is made by the laboratory.

[0023] (2) Plasma cleaning treatment of the substrate surface of hydrophobic materials

[0024] Put the cleaned LLDPE film surface substrate in step (1) into a plasma cleaning machine for plasma cleaning treatment, and introduce hydroxyl groups on the LLDPE film surface substrate after treatment for the preparation of an anti-fog coating. The instrument model used for the plasma cleaning tr...

Embodiment 2

[0031] Embodiment 2: a kind of preparation method of anti-fog coating, the conditions and steps of preparation are as follows:

[0032] The treatment of the hydrophobic material substrate, the plasma cleaning treatment of the surface of the hydrophobic material substrate and the preparation process of the building blocks are the same as in Example 1.

[0033] In the preparation process of the multilayer film coating, the treated LLDPE film surface substrate is immersed in a 70° C. saturated boric acid solution for 20 minutes; the described immersion is in a 5 wt % PVA solution for 50 minutes. Repeat the operation for 3 cycles to obtain 3 cycles of layered assembled membrane coatings.

Embodiment 3

[0034] Embodiment 3: a kind of preparation method of anti-fog coating, the conditions and steps of preparation are as follows:

[0035] The treatment of the hydrophobic material substrate, the plasma cleaning treatment of the surface of the hydrophobic material substrate and the preparation process of the building blocks are the same as in Example 1.

[0036] In the preparation process of the multilayer film coating, the treated LLDPE film surface substrate is immersed in a 70° C. saturated boric acid solution for 30 minutes; the described immersion is in a 5 wt % PVA solution for 60 minutes. Repeat the operation for 3 cycles to obtain 3 cycles of layered assembled membrane coatings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com