Polymer flame-retardant material containing pyrazole flame retardant and preparation method thereof

A technology of flame retardant materials and flame retardants, applied in the field of organic flame retardants, can solve problems such as harmful harmful gases, and achieve the effects of good compatibility, excellent thermal stability, and transparent comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

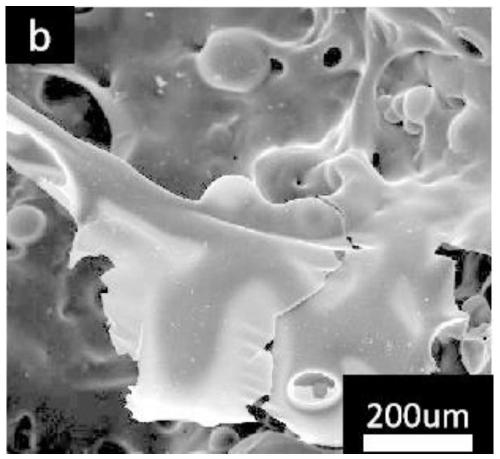

[0031] The polymer flame retardant material containing pyrazole flame retardant proposed by the present invention comprises the following raw materials in parts by weight: 20 parts of epoxy resin prepolymer, 1.5 parts of pyrazole flame retardant, 4,4'-diaminobis 5 parts of benzene methane.

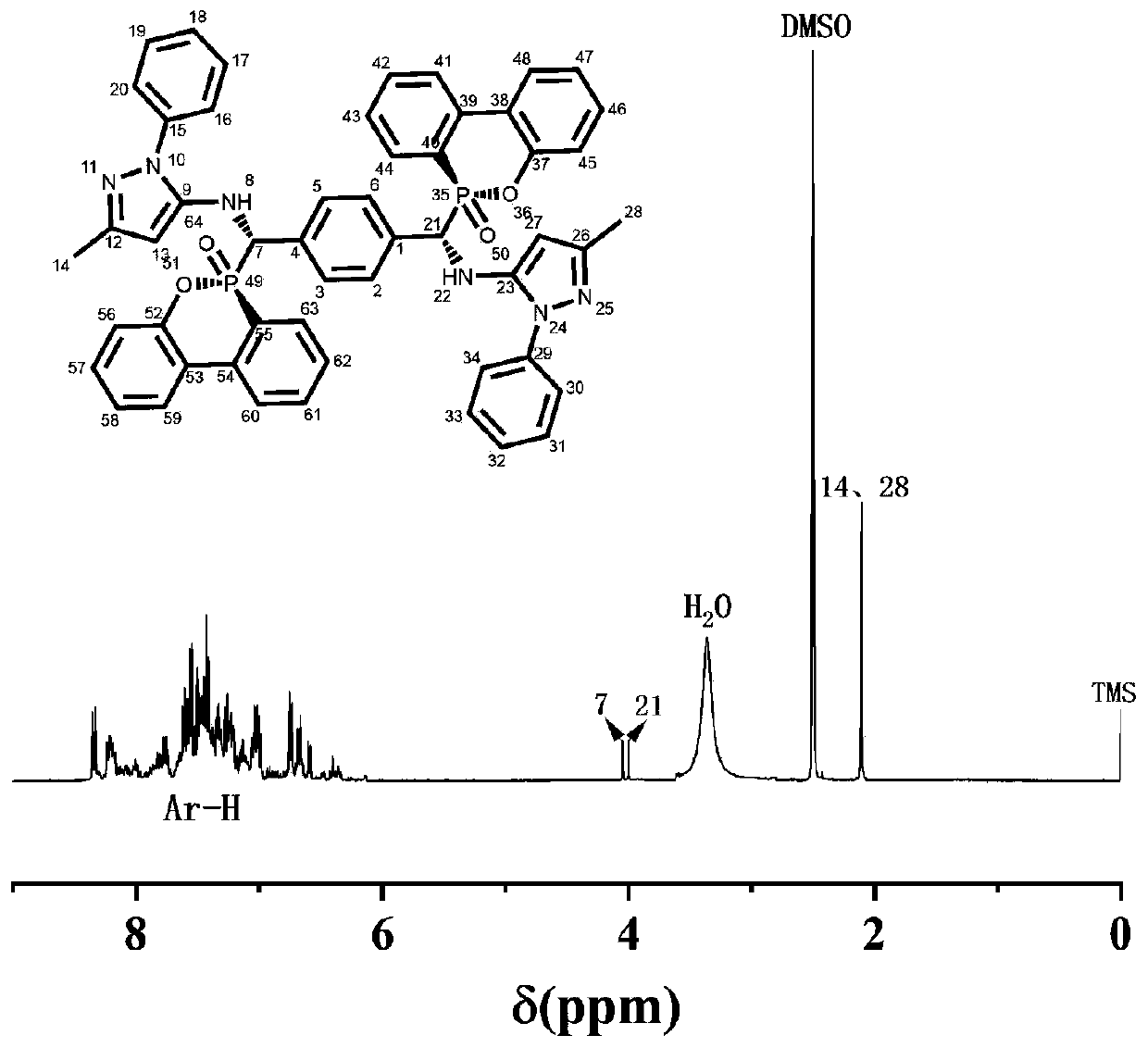

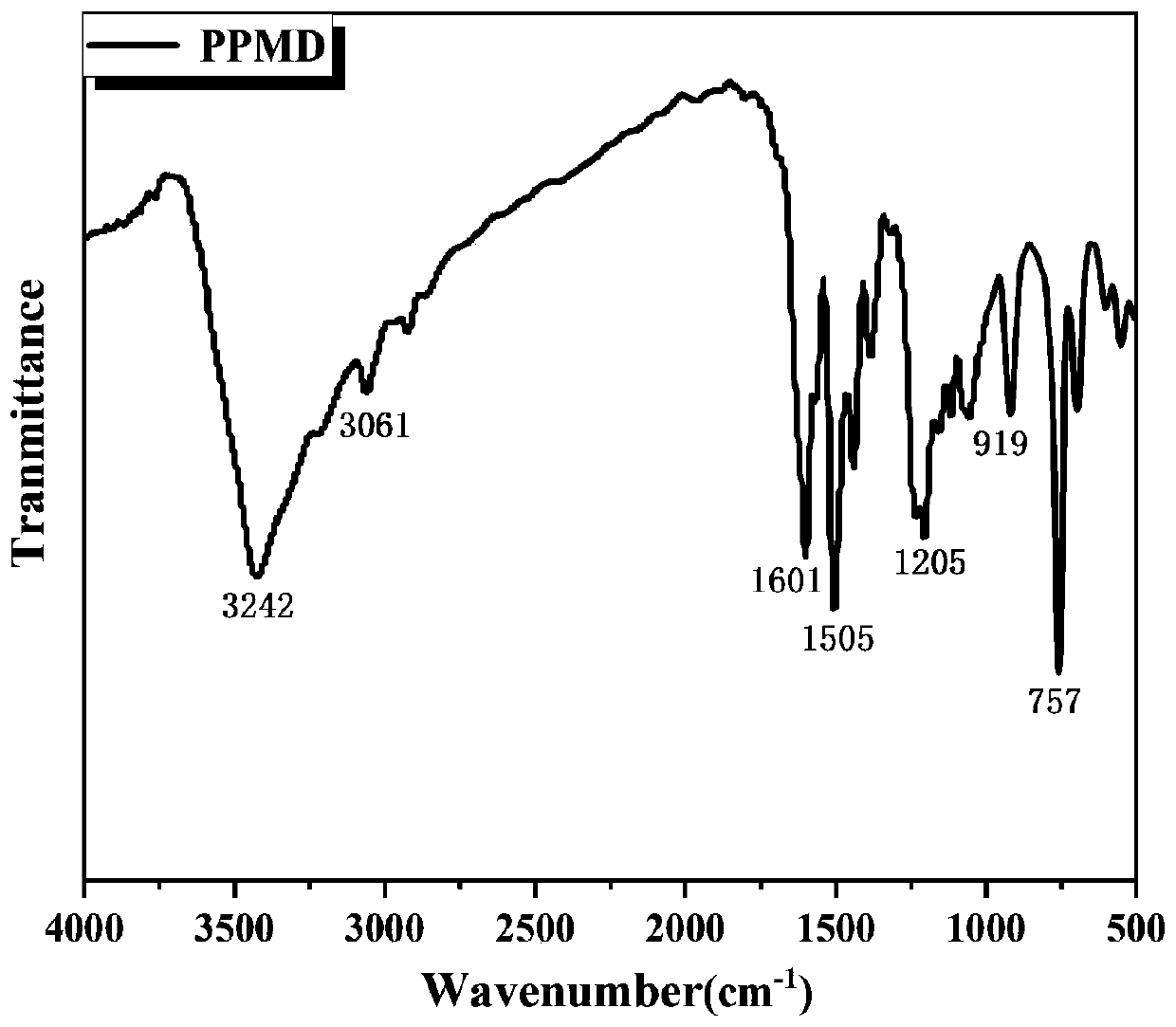

[0032] The method steps of pyrazole flame retardant preparation are as follows:

[0033] S1: Add 5-amino-3-methyl-1-phenylpyrazole, p-benzaldehyde, and the first solvent to the reaction vessel in sequence, and stir at 30°C for 4 hours;

[0034] S2: Add DOPO to the reaction vessel of S1, and react at 30°C for 4 hours;

[0035] S3: Filter the solution after the reaction in S2, dissolve the filtered crude product in a second solvent to remove impurities in the crude product, and dry the solid product after filtration to obtain a pyrazole-rich flame retardant.

[0036] The molar volume ratio of 5-amino-3-methyl-1-phenylpyrazole, p-benzaldehyde, DOPO, and the first solvent is 1mol:0.1mol:0.1m...

Embodiment 2

[0043] The polymer flame retardant material containing pyrazole flame retardant proposed by the present invention includes the following raw materials in parts by weight: 30 parts of epoxy resin prepolymer, 1.8 parts of pyrazole flame retardant, 4,4'-diaminobis 8 parts of benzene methane.

[0044] The method steps of pyrazole flame retardant preparation are as follows:

[0045] S1: Add 5-amino-3-methyl-1-phenylpyrazole, p-benzaldehyde, and the first solvent to the reaction vessel in sequence, and stir at 180°C for 24 hours;

[0046] S2: Add DOPO to the reaction vessel of S1, and react at 180°C for 24 hours;

[0047] S3: Filter the solution after the reaction in S2, dissolve the filtered crude product in a second solvent to remove impurities in the crude product, and dry the solid product after filtration to obtain a pyrazole-rich flame retardant.

[0048] The molar ratio of 5-amino-3-methyl-1-phenylpyrazole, p-benzaldehyde, DOPO, the first solvent, and the second solvent is ...

Embodiment 3

[0055] The polymer flame retardant material containing pyrazole flame retardant proposed by the present invention includes the following raw materials in parts by weight: 25 parts of epoxy resin prepolymer, 1.65 parts of pyrazole flame retardant, 4,4'-diaminobis 6.5 parts of benzene methane.

[0056] The method steps of pyrazole flame retardant preparation are as follows:

[0057] S1: Add 5-amino-3-methyl-1-phenylpyrazole, p-benzaldehyde, and the first solvent to the reaction vessel in sequence, and stir at 105°C for 14 hours;

[0058] S2: Add DOPO to the reaction vessel of S1, and react at 105°C for 14 hours;

[0059] S3: Filter the solution after the reaction in S2, dissolve the filtered crude product in a second solvent to remove impurities in the crude product, and dry the solid product after filtration to obtain a pyrazole-rich flame retardant.

[0060]The molar volume ratio of 5-amino-3-methyl-1-phenylpyrazole, p-benzaldehyde, DOPO, and the first solvent is 1mol:5mol:5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com