Preparation method of cell

A battery cell and negative electrode technology, which is applied in the field of battery cell preparation, can solve the problems of unstable battery energy density and risks in the processing process, and achieve the effects of preventing the risk of lithium precipitation, improving the pass-through rate and reducing the excess ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

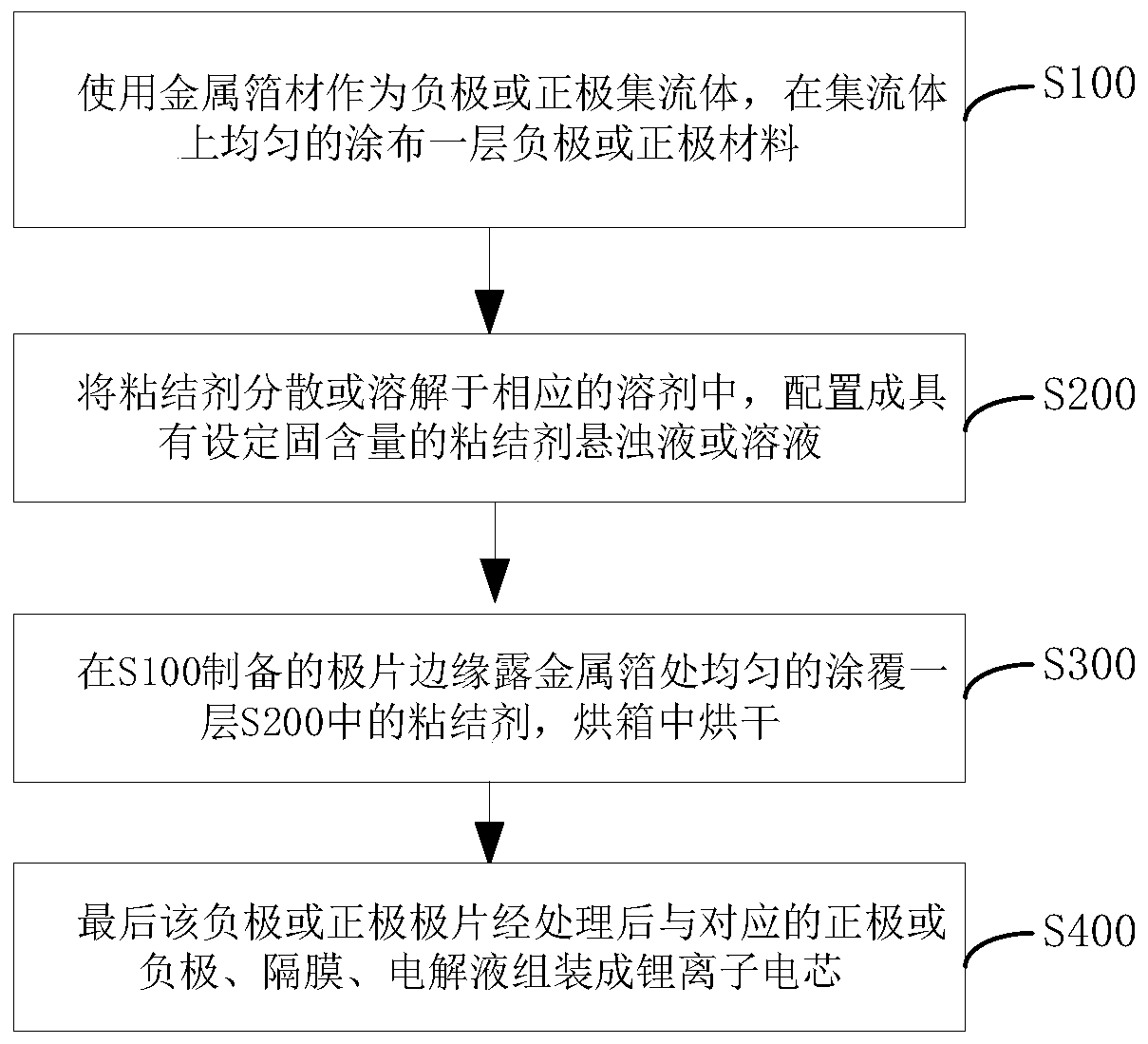

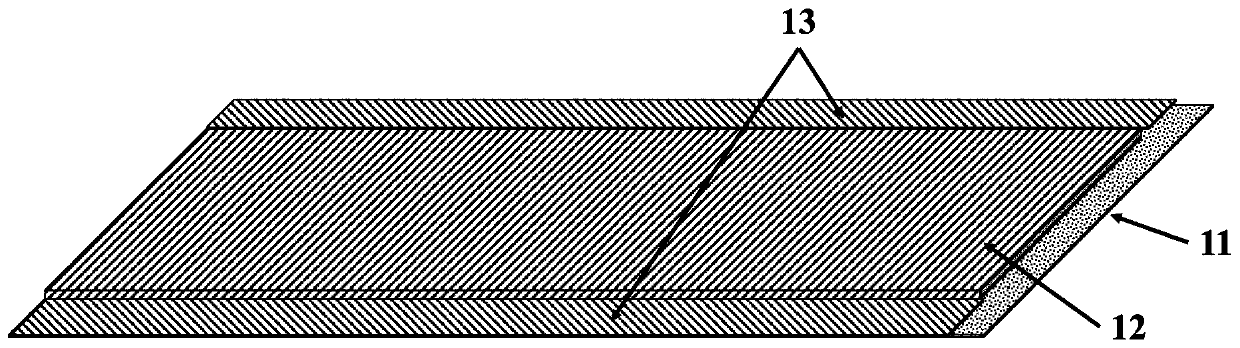

[0030] Such as figure 1 As shown, the manufacturing method of the battery cell in this embodiment includes the following steps:

[0031] S100. Use metal foil as the negative electrode or positive electrode current collector, and coat a layer of negative or positive electrode material uniformly on the current collector;

[0032] S200: Disperse or dissolve the binder in a corresponding solvent, and configure it into a binder suspension or solution with a set solid content;

[0033] S300. Coat a layer of adhesive in S200 evenly on the edge of the pole piece prepared by S100 where the metal foil is exposed, and dry it in an oven;

[0034] S400. Finally, the negative or positive pole piece is processed and assembled with the corresponding positive or negative electrode, separator, and electrolyte to form a lithium ion battery cell.

[0035] among them,

[0036] The thickness of the metal foil in the S100 is 5um-20um.

[0037] The binder in the S200 includes polyvinylidene fluoride (PVDF), sodi...

Embodiment 1

[0047] Use 5um metal copper foil as the negative electrode current collector, and evenly coat a layer of graphite negative electrode slurry, and dry it in a coating oven; dissolve the aqueous PAA in water to make a solution with a solid content of 40%, uniform Coated on the edge exposed metal foil, dried in an oven, and finally processed by rolling and slitting; the corresponding lithium iron phosphate positive electrode is assembled into a battery with an N / P ratio of 1.0 and an Overhang of 0 mm.

Embodiment 2

[0049] Use 8um metal aluminum foil as the negative electrode current collector, and evenly coat a layer of nickel cobalt lithium manganate (NCM622) positive electrode slurry, and dry it in a coating oven; dissolve the oily PVDF in NMP to make a solid content of The 7% solution is evenly coated on the edge of the exposed metal foil, dried in an oven, and finally processed by rolling and slitting; the corresponding silicon oxide negative electrode has an N / P ratio of 1.08 and an Overhang of 1mm. Assemble into a battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com