Method for reducing vomitoxin content of wheat, wheat flour and flour product

A technology of vomitoxin and wheat flour, which is applied in the field of grain processing, can solve the problems of residual toxic substances, restrictions, loss of nutrients, etc., and achieve the effects of avoiding the loss of good wheat, ensuring the quality and safety of wheat, and reducing the content of toxins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

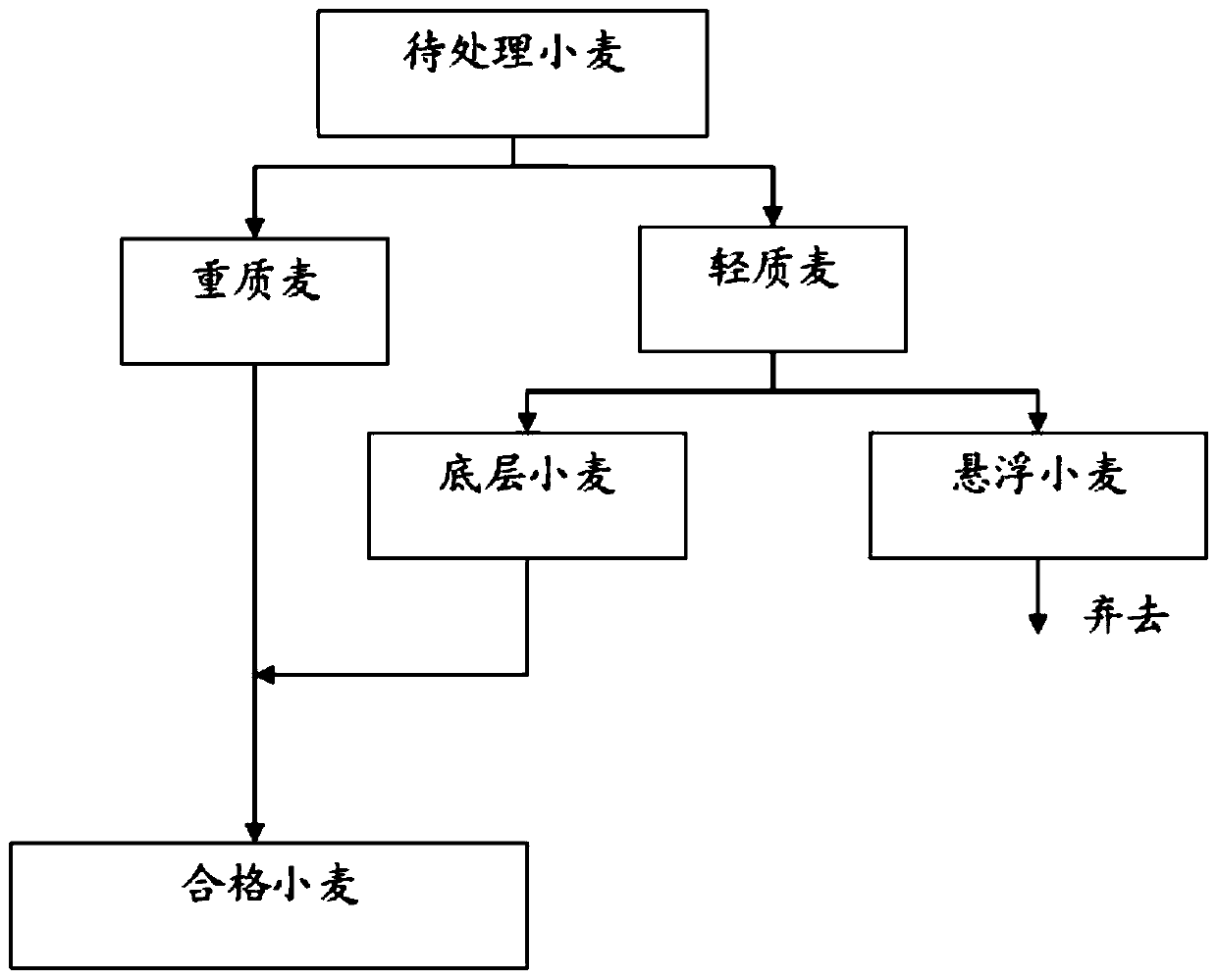

[0045] (1) Send the wheat to be processed into the wheat specific gravity classifier, so that the light wheat, heavy wheat and other impurities (sand, mud, etc.) are discharged from different outlets, and the light wheat and heavy wheat are collected. wheat, wherein the weight of the light wheat is 31% of the weight of the wheat to be treated.

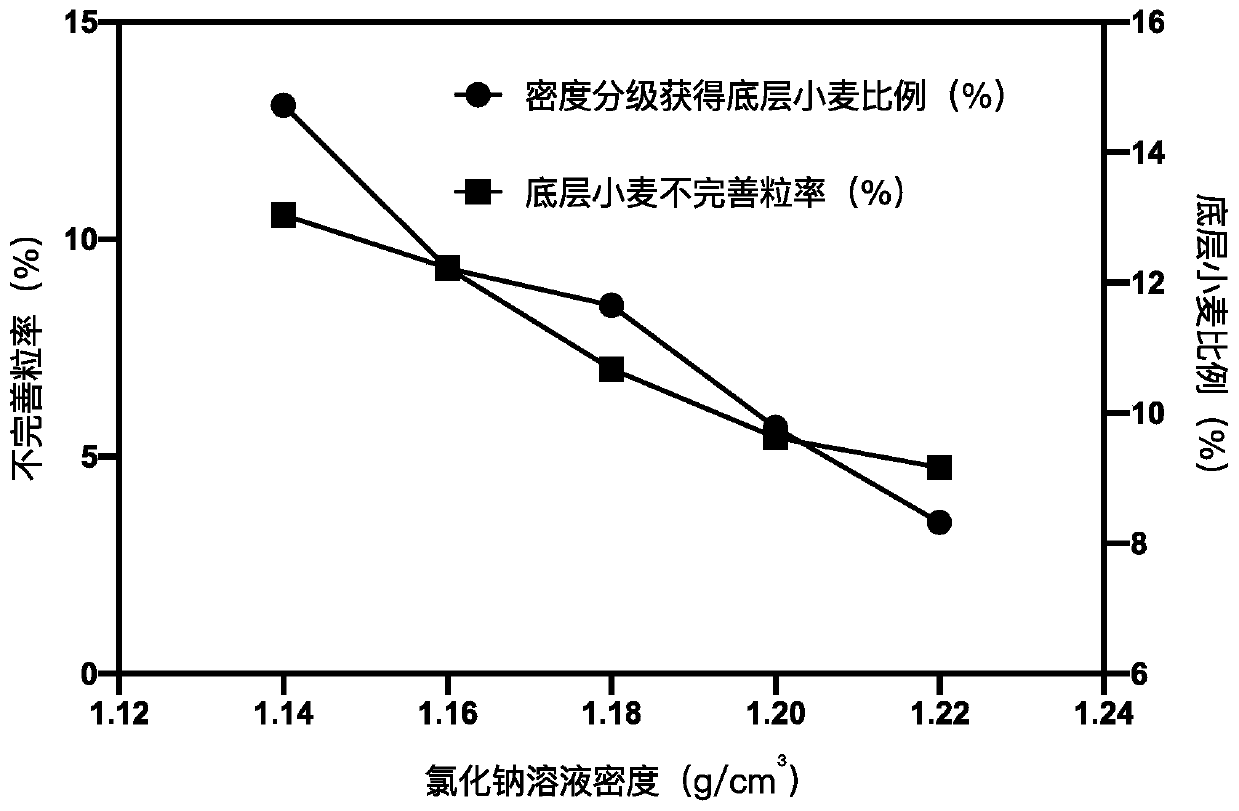

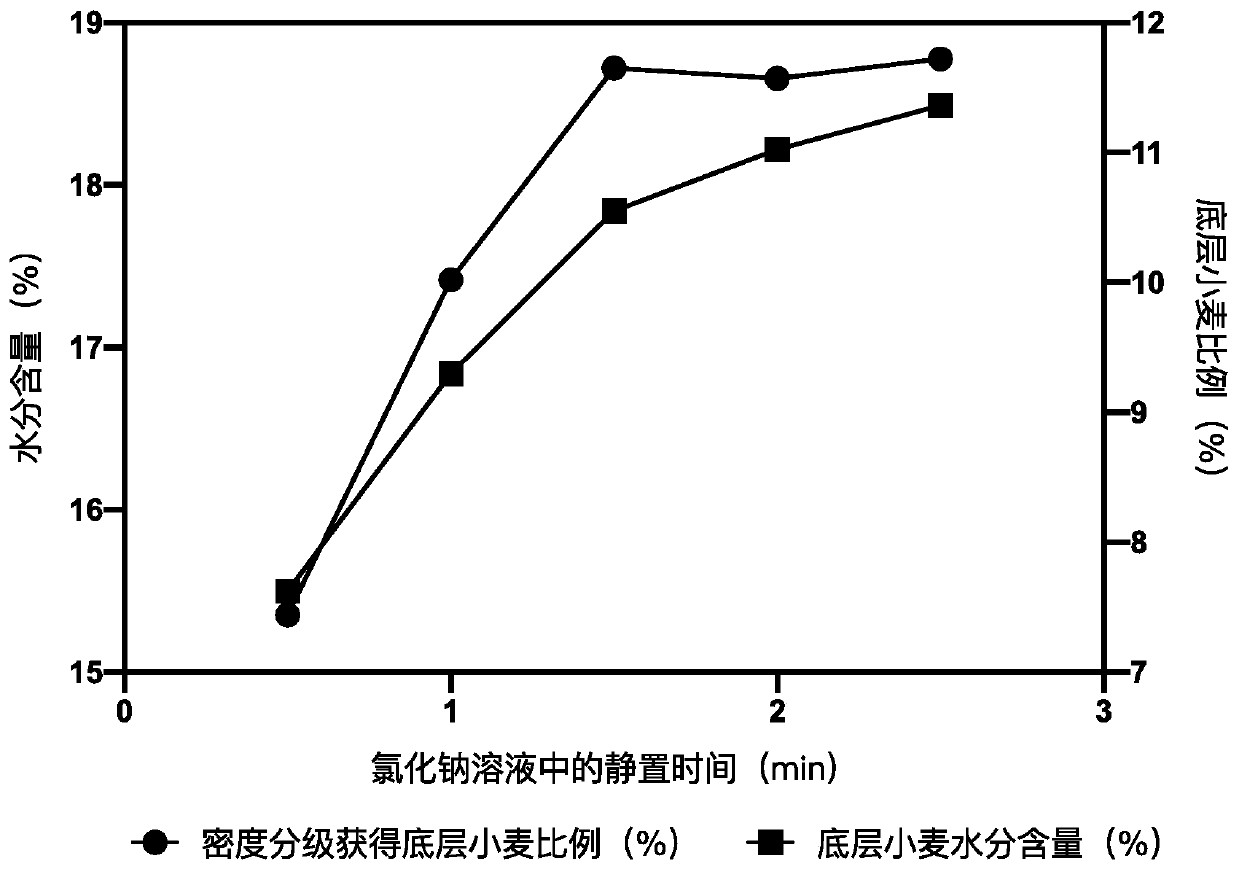

[0046] (2) According to the volume ratio of light wheat: sodium chloride solution = 1:7, place light wheat at a density of 1.18g / cm 3 In the sodium chloride solution, after stirring for 5s, let it stand for 1.5min, the light wheat is separated into suspended wheat grains and sunken wheat grains in the sodium chloride solution. Remove the suspended wheat and collect the bottom wheat.

[0047] (3) Drying the bottom wheat with hot air until the moisture content of the wheat is less than 14 wt%, and mixing the dried bottom wheat with the heavy wheat obtained in step (1) to obtain qualified wheat.

Embodiment 2

[0049] Except changing the density of the sodium chloride solution in step (2) into 1.14g / cm 3 Except, other steps are all identical with embodiment 1.

Embodiment 3

[0051] Except changing the density of the sodium chloride solution in step (2) into 1.16g / cm 3 Except, other steps are all identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com