A kind of neroli oil capsule dry beads, its preparation method and its application in tobacco

A technology of neroli oil and capsules, which is applied in the field of tobacco to achieve the effects of large air flow, good slow-release effect, high open porosity and fragrance attachment rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

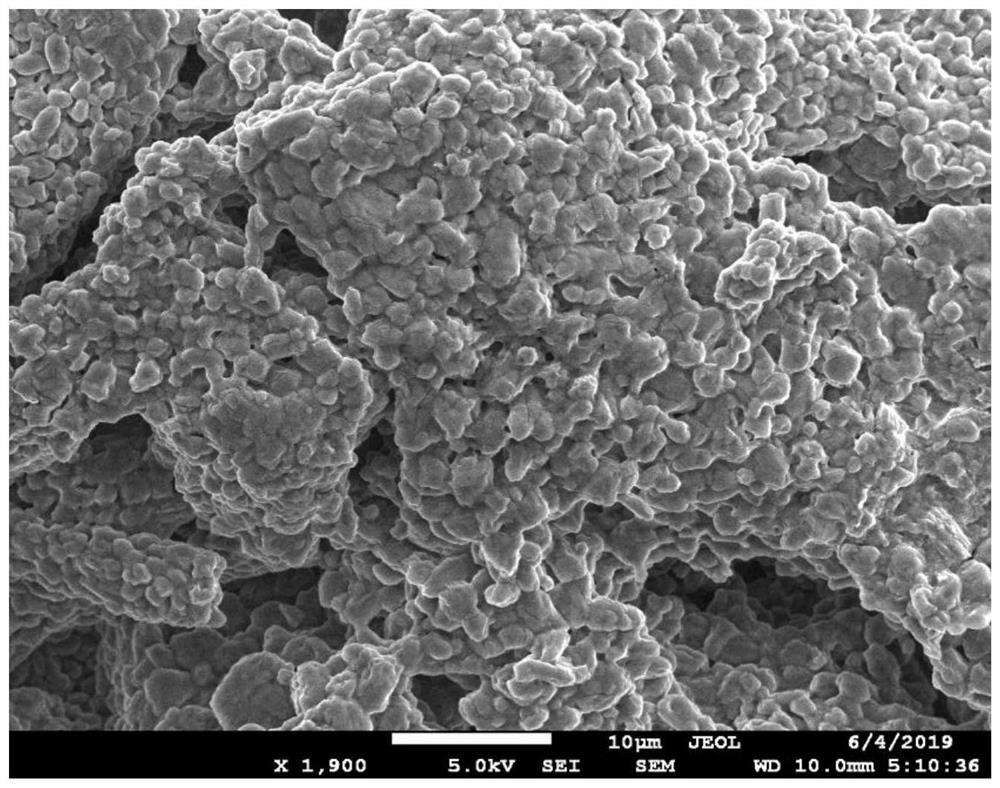

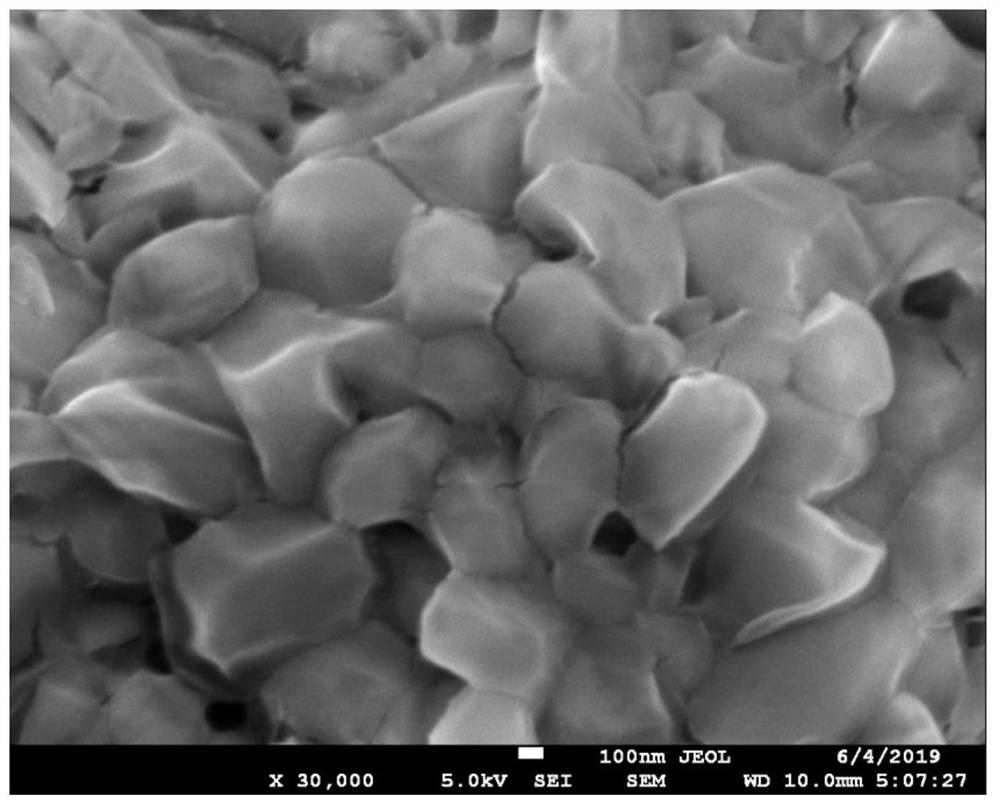

Image

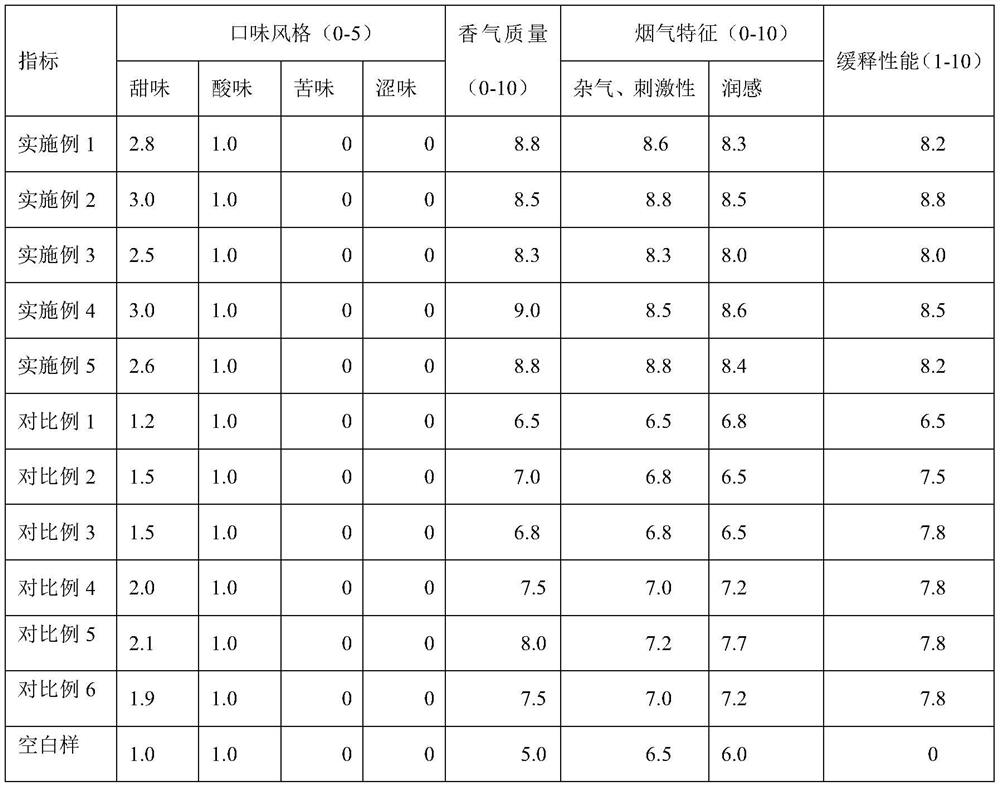

Examples

Embodiment 1

[0028] Get 120mg molecular weight and be 50KDa chitosan, be dissolved in 100ml mass fraction and be in the glacial acetic acid solution of 1%, ultrasonic dissolve 30min, make chitosan dissolve completely; Emulsifier Tween 20 and neroli oil are with the ratio of 240mg:240mg Mix, use magnetic stirrer to carry out pre-emulsification with 500r / min stirring 10min; The complete chitosan solution of gained dissolving is mixed with the mixed solution of pre-emulsified complete neroli oil and emulsifier, placed in the cell disruptor, with Ultrasound at 50% power for 10 minutes to obtain an emulsion; use a sodium hydroxide solution with a concentration of 2mol / L to adjust the emulsion to a pH value of 5.0, and add 5ml of a sodium tripolyphosphate solution with a mass concentration of 16mg / ml under stirring at 500r / min , continue magnetic stirring for 90 min to ensure complete reaction, and obtain neroli oil nano-microcapsule emulsion, and obtain neroli oil nano-microcapsule powder after ...

Embodiment 2

[0032] Take 120mg of chitosan with a molecular weight of 150KDa, dissolve it in 100ml of glacial acetic acid solution with a mass fraction of 1%, and ultrasonically dissolve it for about 30min to completely dissolve the chitosan; mix the emulsifier Tween 20 and neroli oil at a ratio of 240mg:300mg Mix, use magnetic stirrer to carry out pre-emulsification with 500r / min stirring 10min; The complete chitosan solution of gained dissolving is mixed with the mixed solution of pre-emulsified complete neroli oil and emulsifier, placed in the cell disruptor, with Ultrasound at 30% power for 10 minutes to obtain an emulsion; use a sodium hydroxide solution with a concentration of 2mol / L to adjust the pH value of the emulsion to 5.2, and add 5ml of a sodium tripolyphosphate solution with a mass concentration of 12mg / ml under stirring at 500r / min , and continue magnetic stirring for 30 minutes to ensure complete reaction to obtain neroli oil nano-microcapsule emulsion, and obtain neroli oi...

Embodiment 3

[0036] Get 180mg molecular weight and be the chitosan of 450KDa, be dissolved in 100ml mass fraction and be in the glacial acetic acid solution of 1%, ultrasonic dissolving 30min, chitosan is completely dissolved; Proportionally mixed, using a magnetic stirrer to stir at 500r / min for 10min to carry out pre-emulsification; the resulting dissolved chitosan solution is mixed with the mixture of pre-emulsified complete neroli oil and emulsifier, placed in a cell disruptor, Ultrasound at 50% power for 10 minutes to obtain an emulsion; use a sodium hydroxide solution with a concentration of 2 mol / L to adjust the pH of the emulsion to 4.8, and add a sodium tripolyphosphate solution with a mass concentration of 18 mg / ml under stirring at 500 r / min 5ml, and continue magnetic stirring for 90min to ensure complete reaction to obtain neroli oil nano-microcapsule emulsion, and obtain neroli oil nano-microcapsule powder after freeze-drying. The particle size of the obtained nano-microcapsul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com