Preparation and application of lithium ion battery electrode material

A lithium-ion battery and electrode material technology, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve problems affecting lithium storage research, only reversible capacity, etc., and achieve the effect of simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

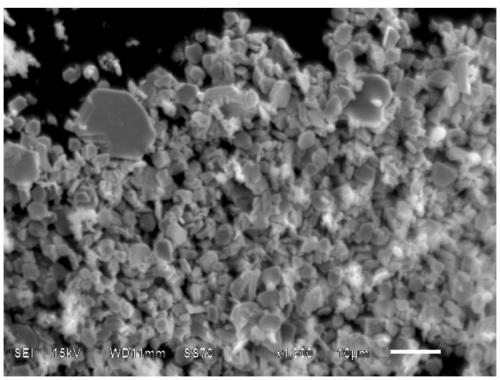

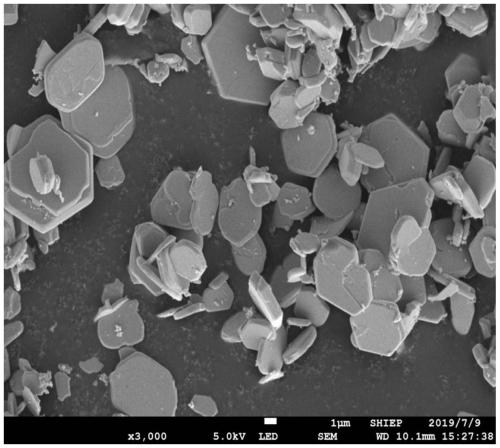

[0040] 2.527g of selenium powder and 1.472g of niobium powder were mixed evenly by hand grinding in a mortar for 1 hour, and then packed in a vacuum quartz tube. After the quartz plug was sealed, the furnace plug was used for secondary sealing protection. Then, the tube furnace was pre-passed with nitrogen for half an hour, and after exhausting the air, the tube furnace was sealed. Then, in a tube furnace, the temperature was raised to 750°C at a rate of 5°C / min and kept at a constant temperature for 3 hours, and then naturally cooled to room temperature to obtain the product niobium diselenide material, which consists of a hexagonal material with a plane size of 1-5 μm and a thickness of 100 nm-1 μm. Lamellar composition, product purity 100%, product yield 93%

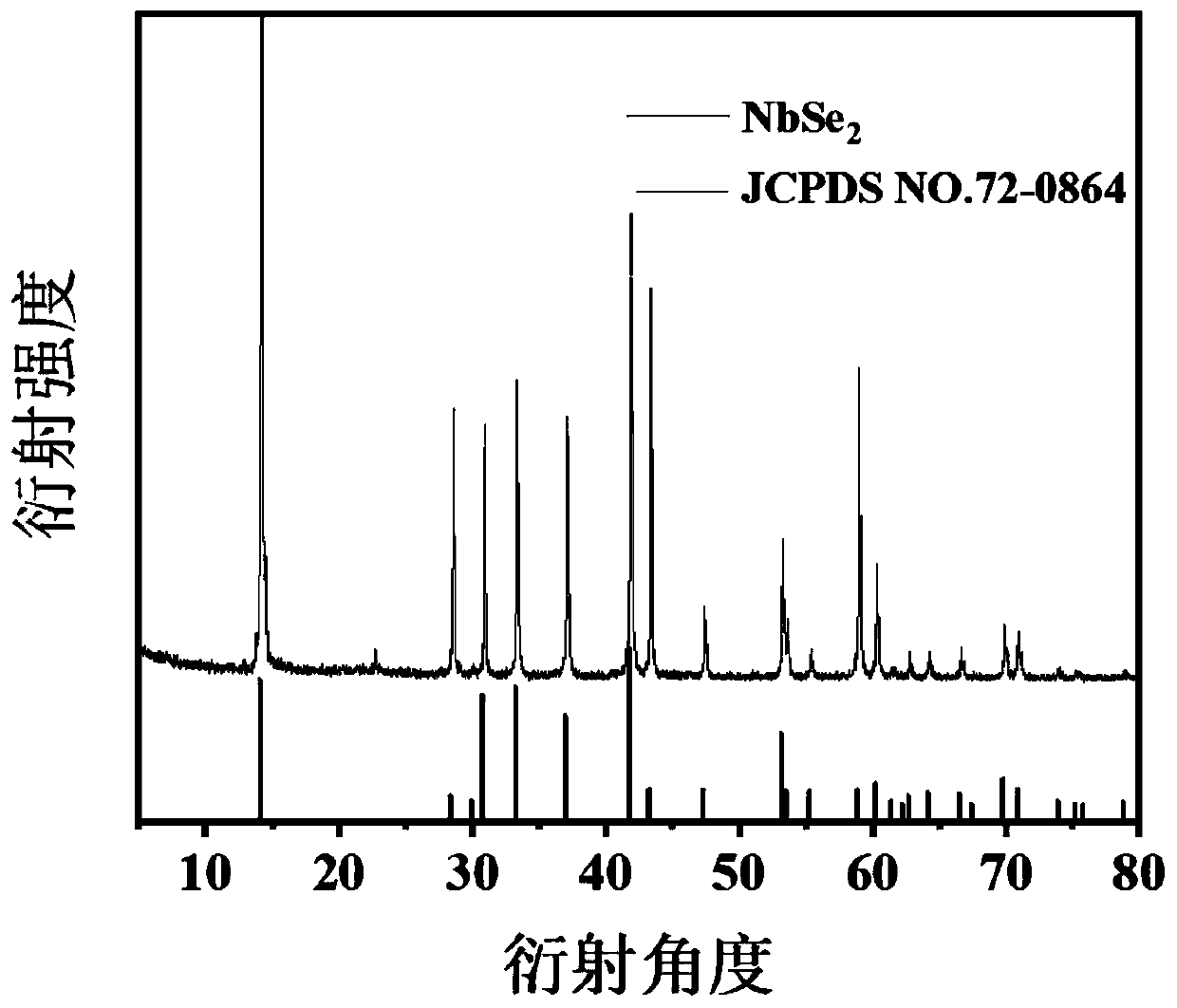

[0041] figure 1 It is the XRD pattern of the niobium diselenide material, and Fig. 2 is the SEM image of the prepared niobium diselenide material. As can be seen from the figure, the peak position of the XRD spectru...

Embodiment 2

[0043] 0.93g of niobium powder and 1.975g of selenium powder were mixed uniformly by wet ball milling, and after drying, they were packed in a vacuum quartz tube and vacuum-sealed using a vacuum sealing machine. Put it into a tube furnace and raise the temperature to 600°C at a rate of 10°C / min and keep it at a constant temperature for 3 hours, then cool it down to room temperature naturally to obtain the product niobium diselenide material. The purity of the product is 76%, with some impurity phase NbSe 3 , The product yield was 92%.

Embodiment 3

[0045] Mix 1.1g of niobium powder and 2.2g of selenium powder evenly by magnetic force, and after drying, put it in a vacuum quartz tube, seal it with a quartz plug, and then use a furnace plug for secondary sealing protection. Then, pre-pass the tube furnace with argon for half an hour, and then seal the tube furnace after exhausting the air. Raise the temperature of the tube furnace to 800°C at a rate of 15°C / min and keep it at a constant temperature for 10 hours, then naturally cool to room temperature to obtain the product niobium diselenide material. The product purity is 100%, and the product yield is 93%. happened in the process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com