A kind of two-component adhesive layer polyurethane resin for bronzing and its preparation method

A polyurethane resin and adhesive layer technology, which is applied in the field of two-component adhesive layer polyurethane resin for bronzing and its preparation, can solve the problems of difficult operation of the production process, system agglomeration or adhesion, etc., to achieve excellent product performance and overcome system agglomeration. or glue, the effect of improving the strength after curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A kind of preparation method of bronzing of the present invention uses two-component adhesive layer polyurethane resin, comprises the steps:

[0039] (1) Polyester polyol A, polyester polyol B, self-made polyfunctionality chain extender, trimethylolpropane, small molecule chain extender, antioxidant, catalyst, 55-80% of butane Put the ketone into a container with a temperature control and stirring device, keep the temperature at 50-60°C, and stir for 30-50 minutes;

[0040] (2) Add diisocyanate, heat up to 70-80°C, react for 100-150min, when the viscosity reaches 100-160Pa·s / 70°C, add the remaining butanone, add terminator, stir until no diisocyanate remains , and continue to stir for 60-90 minutes to obtain the two-component adhesive layer polyurethane resin for bronzing, with a viscosity of 100-160 Pa·s / 25°C.

Embodiment 1

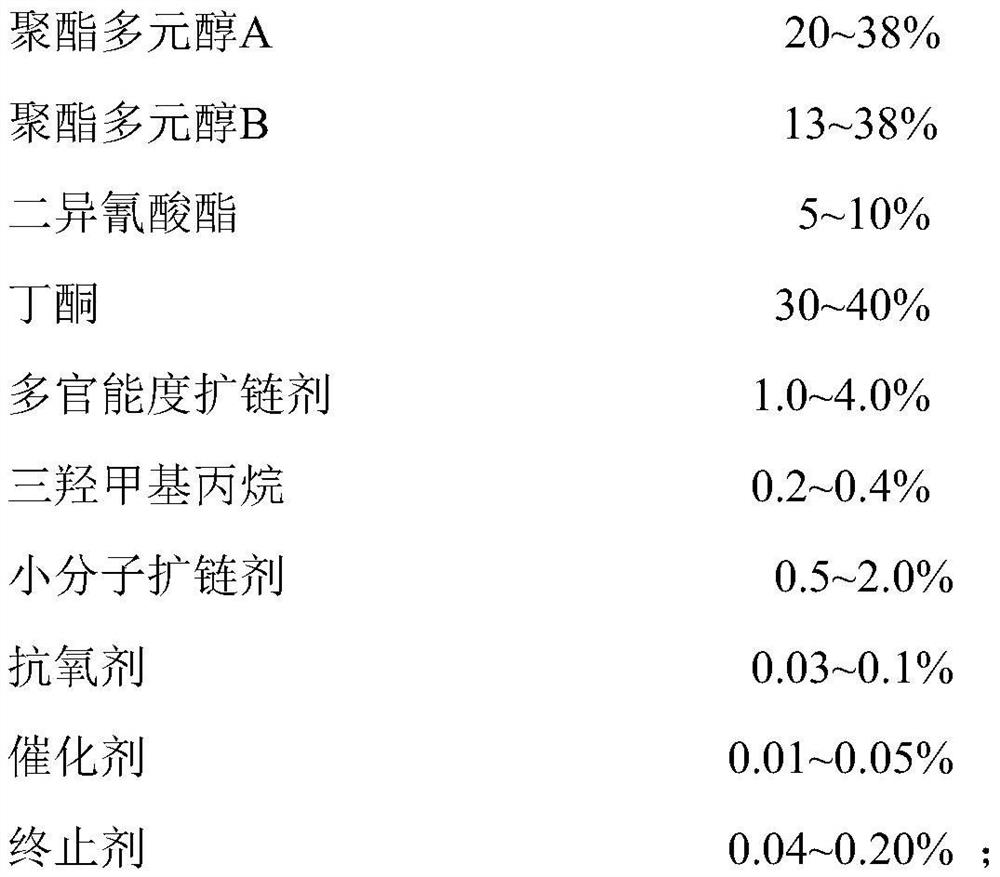

[0043] A two-component adhesive layer polyurethane resin for bronzing, consisting of the following components in percentage by weight:

[0044]

[0045] The preparation method of described hot stamping with two-component adhesive layer polyurethane resin comprises the steps:

[0046] (1) Put polyester polyol A, polyester polyol B, self-made polyfunctionality chain extender, trimethylolpropane, small molecule chain extender, antioxidant, catalyst, 70% butanone into the recipe In a container with a temperature control and stirring device, keep the temperature at 60°C and stir for 30 minutes;

[0047](2) Add diisocyanate, heat up to 75°C, react for 120min, when the viscosity reaches 140Pa·s / 70°C, add the remaining butanone, add 1,3-butanediol, stir until no diisocyanate remains, Stirring was continued for 70 minutes to obtain the two-component adhesive layer polyurethane resin for bronzing with a viscosity of 120 Pa·s / 25°C.

Embodiment 2

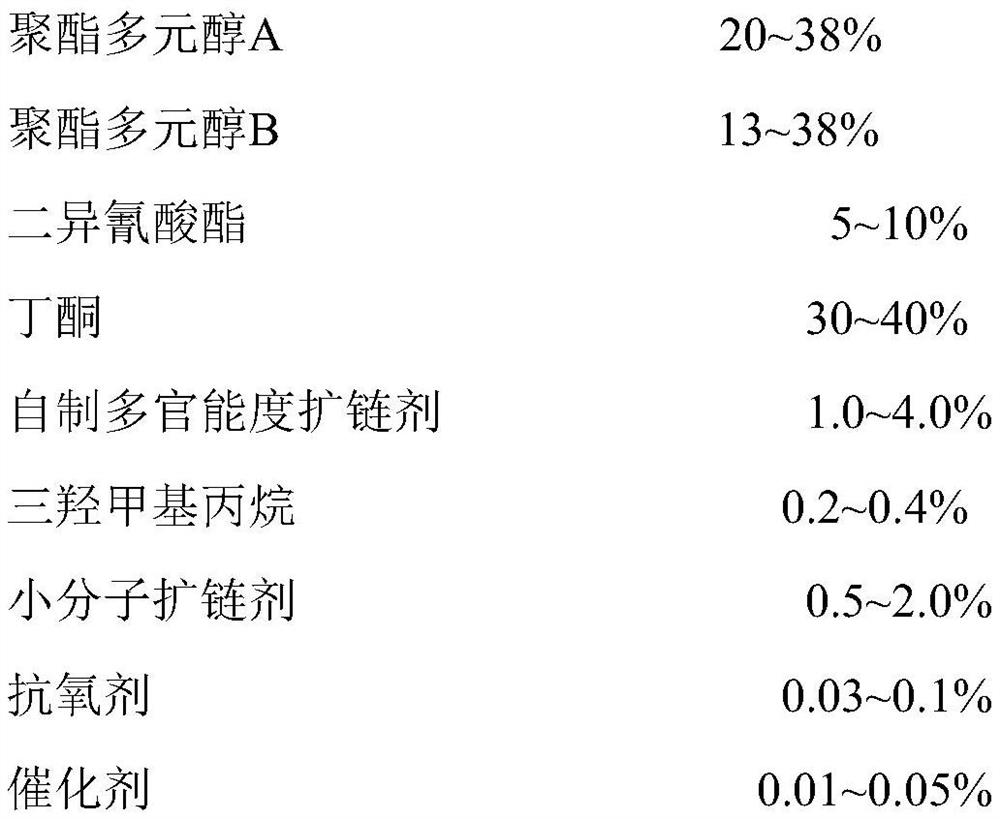

[0049] A two-component adhesive layer polyurethane resin for bronzing, consisting of the following components in percentage by weight:

[0050]

[0051]

[0052] The preparation method of described hot stamping with two-component adhesive layer polyurethane resin comprises the steps:

[0053] (1) Put polyester polyol A, polyester polyol B, self-made polyfunctionality chain extender, trimethylolpropane, small molecule chain extender, antioxidant, catalyst, 60% butanone in formula amount into In a container with a temperature control and stirring device, keep the temperature at 60°C and stir for 30 minutes;

[0054] (2) Add diisocyanate, heat up to 75°C, react for 120min, when the viscosity reaches 150Pa·s / 70°C, add the remaining butanone, add 1,3-butanediol, stir until no diisocyanate remains, Stirring was continued for 80 minutes to obtain the two-component adhesive layer polyurethane resin for bronzing with a viscosity of 135 Pa·s / 25°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com