A kind of polypropylene-based composite material for cladding metal and its preparation method and application

A composite material, polypropylene-based technology, applied in the field of composite materials, can solve the problems of flame retardancy, light weight and low density, and achieve the effects of prolonging the service life, reducing material separation, and improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

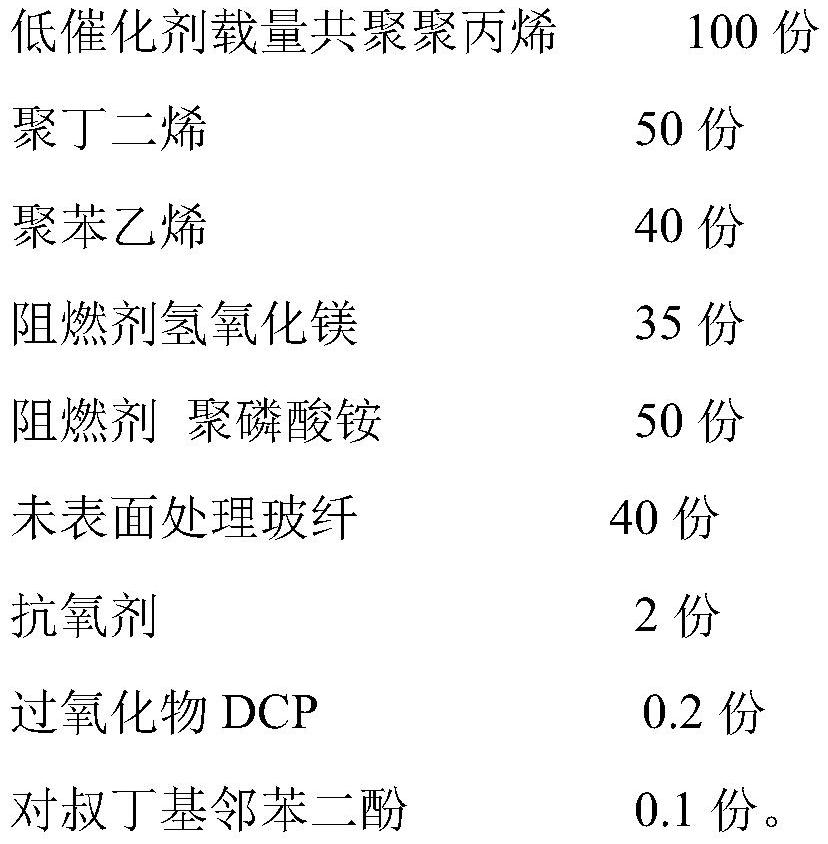

[0042] This example provides a polypropylene-based composite material for cladding metal, and its raw material formula includes:

[0043]

[0044] The other raw materials except the peroxide DCP and p-tert-butylcatechol were put into a low speed mixer and stirred for 5 minutes. After each component is mixed evenly, use a screw extruder (screw diameter 50mm) to extrude, set the screw temperature according to the following table, set the main engine speed to 35Hz, 0.2 part of peroxide DCP 2 / 4 section (temperature fourth stage), 0.1 part of p-tert-butyl catechol was added in 3 / 4 stage (the seventh stage of temperature), and the polypropylene-based composite material for metal coating was prepared by extrusion and granulation.

[0045]

Embodiment 2

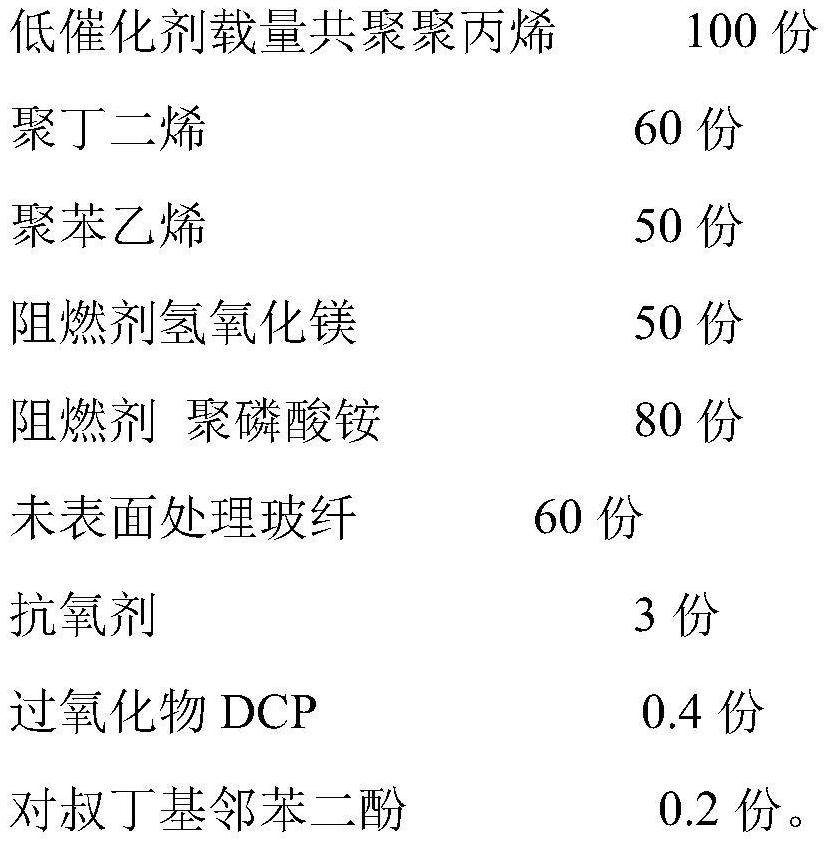

[0047] This example provides a polypropylene-based composite material for cladding metal, and its raw material formula includes:

[0048]

[0049] The preparation method is the same as in Example 1.

Embodiment 3

[0051] This example provides a polypropylene-based composite material for cladding metal, and its raw material formula includes:

[0052]

[0053] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com