Equipment and method for continuous takt type vacuum heat treatment of workpieces

A vacuum heat treatment and heat treatment chamber technology, applied in heat treatment equipment, heat treatment furnaces, quenching devices, etc., can solve the problems of difficult mass continuous production, high energy consumption, long production cycle, etc., to achieve high production efficiency, low energy consumption, Stable quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

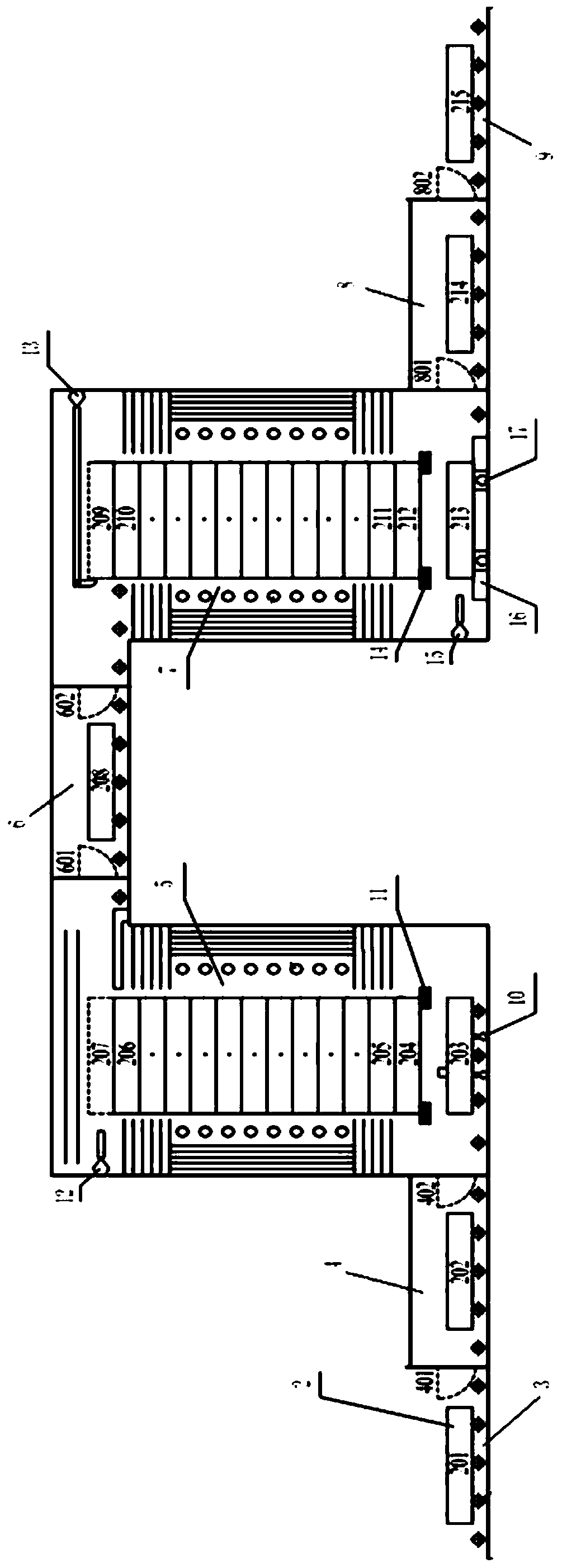

[0033] High speed steel turning blade (material: SKH-51) continuous vacuum quenching and tempering

[0034] (1) No-load installation of workpiece tray 2: Open flap valve 1 401, flap valve 2 402, flap valve 3 601 and flap valve 4 602, open the transmission mechanism, and send multiple empty workpiece trays 2 continuously Form 204 to 206 lamination layers in the high-temperature vacuum heat treatment chamber 5, and send them into the lamination layers forming 210-212 in the low-temperature vacuum heat treatment chamber 7; close flap valve one 401, flap valve two 402, flap valve three 601, Flap valve four 602, flap valve five 801 and flap valve six 802;

[0035] (2) Open the vacuum acquisition system; open the vacuum valves of the entrance transition chamber 4, high temperature vacuum heat treatment chamber 5, gas quenching chamber 6, low temperature vacuum heat treatment chamber 7 and outlet transition chamber 8, so that the vacuum degree is maintained at 5X10 -2 Pa;

[0036] ...

Embodiment 2

[0050] Solid Solution and Aging of Beryllium Bronze High Conductivity Contact Electrode

[0051] (1) No-load installation of workpiece tray 2: Open flap valve 1 401, flap valve 2 402, flap valve 3 601 and flap valve 4 602, open the transmission mechanism, and send multiple empty workpiece trays 2 continuously Form 204 to 206 lamination layers in the high-temperature vacuum heat treatment chamber 5, and send them into the lamination layers forming 210-212 in the low-temperature vacuum heat treatment chamber 7; close flap valve one 401, flap valve two 402, flap valve three 601, Flap valve four 602, flap valve five 801 and flap valve six 802;

[0052] (2) Open the vacuum acquisition system; open the vacuum valves of the entrance transition chamber 4, high temperature vacuum heat treatment chamber 5, gas quenching chamber 6, low temperature vacuum heat treatment chamber 7 and outlet transition chamber 8, so that the vacuum degree is maintained at 5X10 -2 Pa;

[0053] (3) Heating...

Embodiment 3

[0067] Preparation of 6.5wt.% Si high-silicon steel sheet by high-temperature diffusion and Si infiltration on low-silicon steel sheet coated with Si-rich film and low-temperature annealing treatment

[0068] (1) No-load installation of workpiece tray 2: Open flap valve 1 401, flap valve 2 402, flap valve 3 601 and flap valve 4 602, open the transmission mechanism, and send multiple empty workpiece trays 2 continuously Form 204 to 206 lamination layers in the high-temperature vacuum heat treatment chamber 5, and send them into the lamination layers forming 210-212 in the low-temperature vacuum heat treatment chamber 7; close flap valve one 401, flap valve two 402, flap valve three 601, Flap valve four 602, flap valve five 801 and flap valve six 802;

[0069] (2) Open the vacuum obtaining system 18; open the vacuum valves of the entrance transition chamber 4, high temperature vacuum heat treatment chamber 5, gas quenching chamber 6, low temperature vacuum heat treatment chamber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com