Treatment method of precipitation residues in cyanide barren solution

A technology of cyanide barren solution and treatment method, which is applied in the direction of zinc sulfide, improvement of process efficiency, photography process, etc., can solve the problems of lack of sedimentation residue treatment technology, failure to solve disadvantages, etc., and achieve the effect of high-efficiency separation and recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

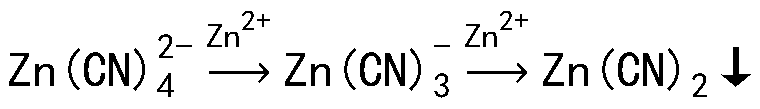

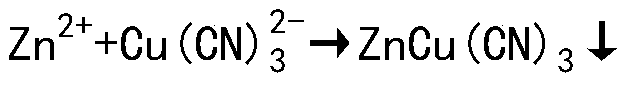

Method used

Image

Examples

Embodiment 1

[0038] The present embodiment provides a kind of processing method for the precipitation slag that is used for cyanide barren solution, comprises the steps:

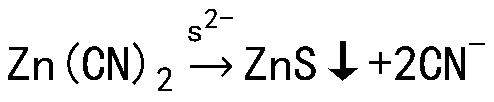

[0039] (1) Put 100g of cyanide barren solution precipitation slag containing 21.9g of zinc element in the sodium sulfide solution of pH=10 according to the liquid-solid ratio of 2:1. After liquid separation, a new slag phase mainly composed of sphalerite (ZnS) can be obtained, and the new slag phase can be sold as a zinc concentrate product or directly used for zinc extraction, and then the Zn element in the precipitated slag of the cyanide barren solution is completed. recycling;

[0040] (2) After recovering the Zn element in step (1) with Cu(CN) 3 2- The ion solution is used as the electrolyte, and then the liquid is used as the electrolyte, and 150A / m is applied 2At a temperature of 60°C, the electrolyte is electrolyzed for 2 hours by electrolysis, the metal copper is directly recovered, and it is recycled by addi...

Embodiment 2

[0043] The present embodiment provides a kind of processing method for the precipitation slag that is used for cyanide barren solution, comprises the steps:

[0044] (1) Put 100g of cyanide barren solution precipitation slag containing 28.9g of zinc element in the sodium hydrosulfide solution of pH=9 according to the liquid-solid ratio of 3:1, and react at room temperature for 60min, and then pass through the reacted solution. After solid-liquid separation, a new slag phase mainly composed of sphalerite (ZnS) can be obtained, and the new slag phase can be sold as a zinc concentrate product or directly used for zinc extraction, and then the Zn in the precipitated slag of the cyanide barren solution is completed. recycling of elements;

[0045] (2) After recovering the Zn element in step (1) with Cu(CN) 3 2- The ion solution is used as the electrolyte, and then the liquid is used as the electrolyte, and 200A / m is applied 2 The cathodic current density, at a temperature of 50 ...

Embodiment 3

[0048] The present embodiment provides a kind of processing method for the precipitation slag that is used for cyanide barren solution, comprises the steps:

[0049] (1) Put 100g of cyanide barren solution precipitation slag containing 30.1g of zinc element in the hydrogen sulfide solution of pH=12 according to the liquid-solid ratio of 5:1. After liquid separation, a new slag phase mainly composed of sphalerite (ZnS) can be obtained, and the new slag phase can be sold as a zinc concentrate product or directly used for zinc extraction, and then the Zn element in the precipitated slag of the cyanide barren solution is completed. recycling;

[0050] (2) After recovering the Zn element in step (1) with Cu(CN) 3 2- The ion solution is used as the electrolyte, and then the liquid is used as the electrolyte, and 300A / m is applied 2 At a temperature of 40°C, the electrolyte is electrolyzed for 4 hours by electrolysis, the metal copper is directly recovered, and recycled by adding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com