LTCC device manufactured based on titanium substrate electroplating pattern transfer method

A technology of pattern transfer and plate electroplating, applied in the field of low temperature co-fired ceramics, to achieve the effect of improving reliability and stability and improving dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

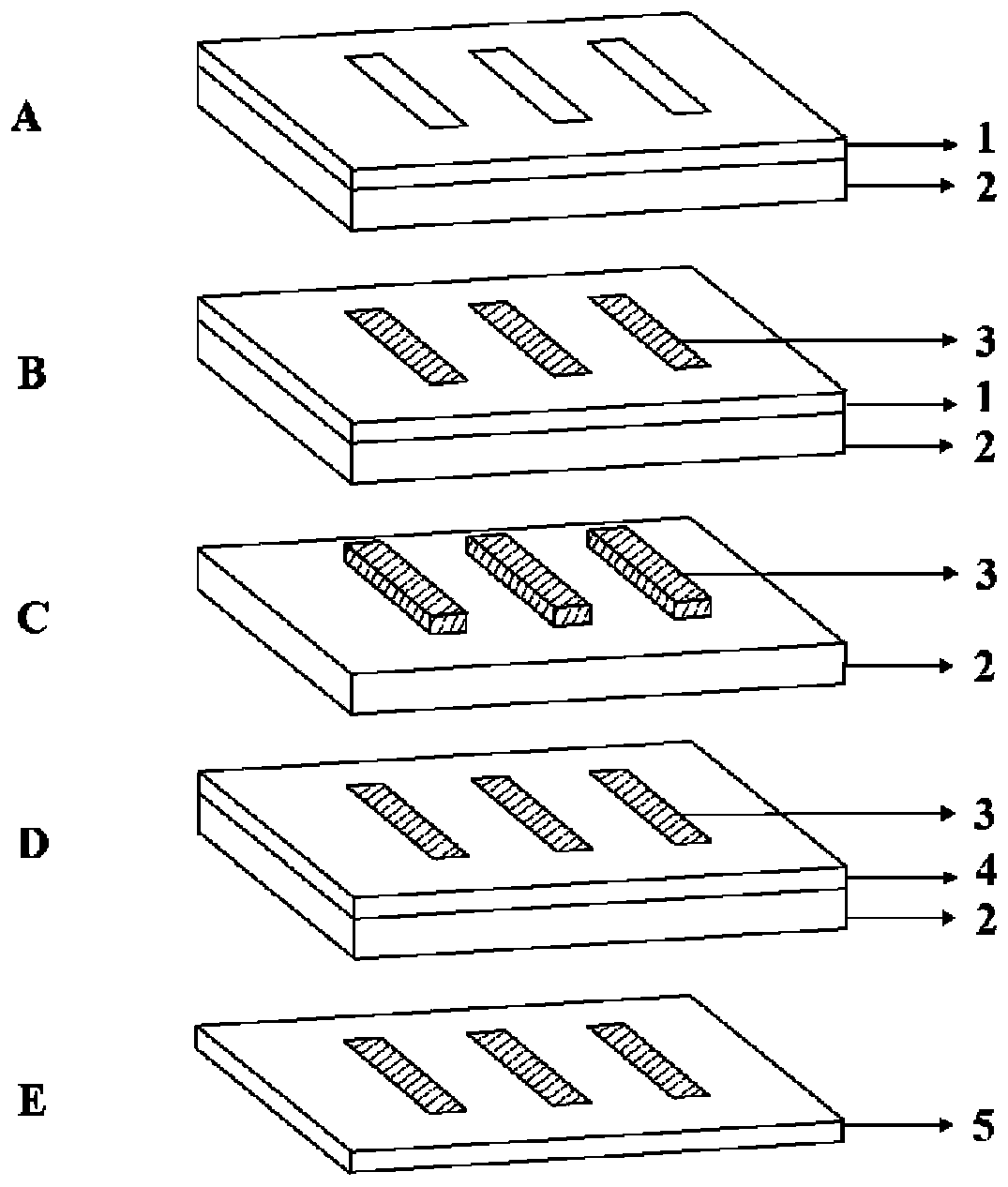

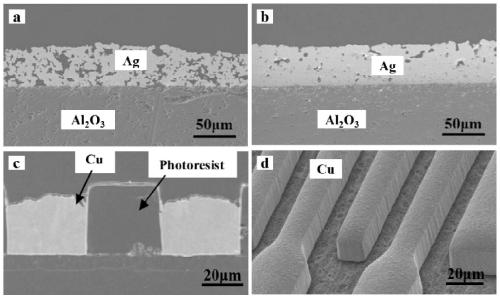

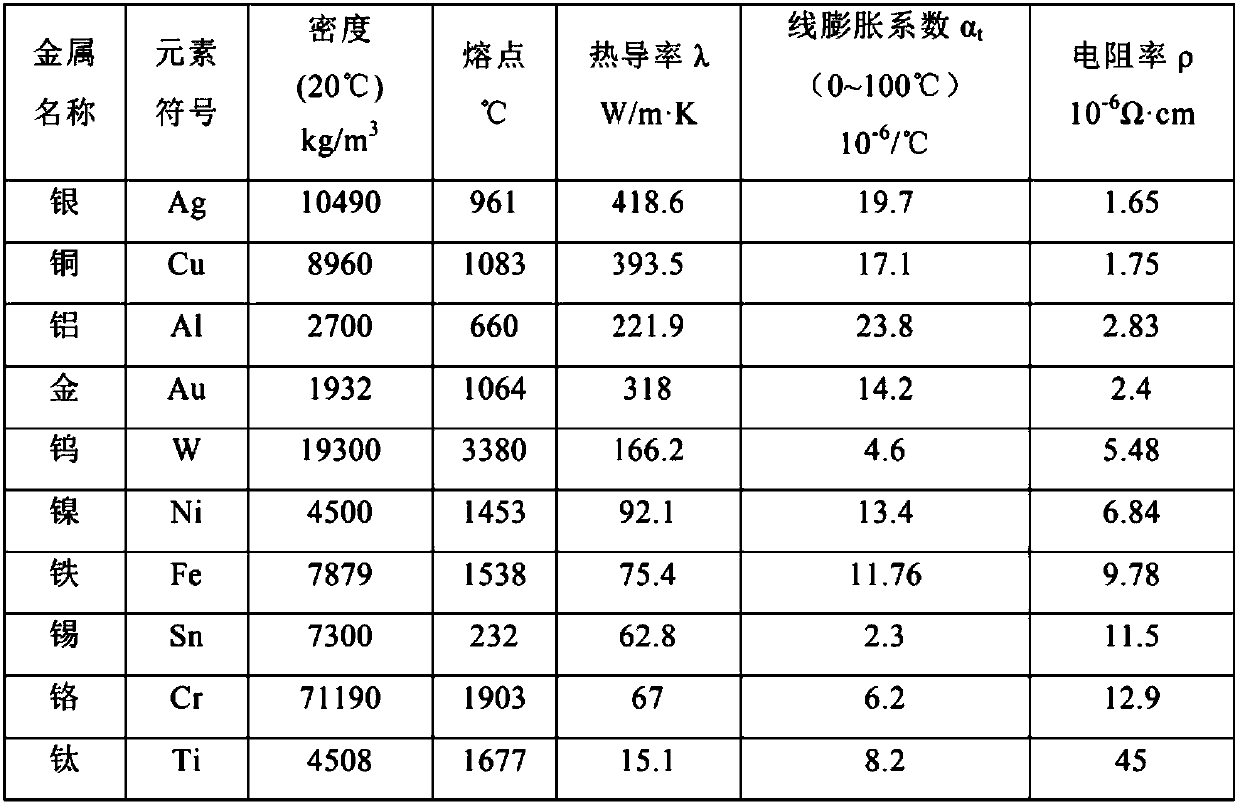

[0071] The preparation process of the LTCC device based on the electroplating pattern transfer method on the titanium substrate is as follows:

[0072] 1) Select a titanium substrate with a surface grain size of ASTM 7 or less and a surface roughness Ra<0.6 μm, clean the surface to keep it clean, and print the photoresist or The solder resist ink is drawn on the surface of the titanium substrate according to the circuit pattern designed on the design drawing, and is made into an anti-plating mask attached to the surface of the titanium substrate through processes such as photocuring or thermal curing, exposure, development, and etching;

[0073]The thickness of the photoresist or solder resist ink is controlled according to the designed parameters; the temperature of the heat curing is controlled and baked in an environment of 100-120 degrees Celsius for 0.5-2 minutes; the light curing is used for irradiation and baking of 0.5-5 minutes with infrared lamp ; Exposure, developme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com