Paper current collector, preparation method thereof, electrode and battery

A current collector, paper technology, applied in the direction of electrode carrier/current collector, secondary battery, battery electrode, etc., can solve the problems of reducing thickness, low safety performance and high density of lithium ion battery, and achieve good strength and waterproof performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

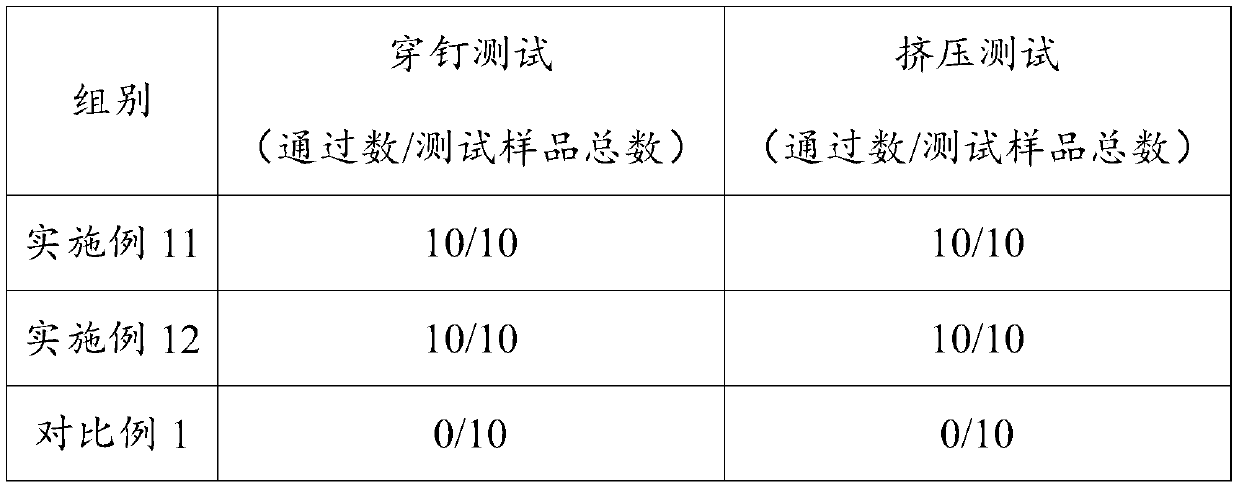

Examples

Embodiment 1

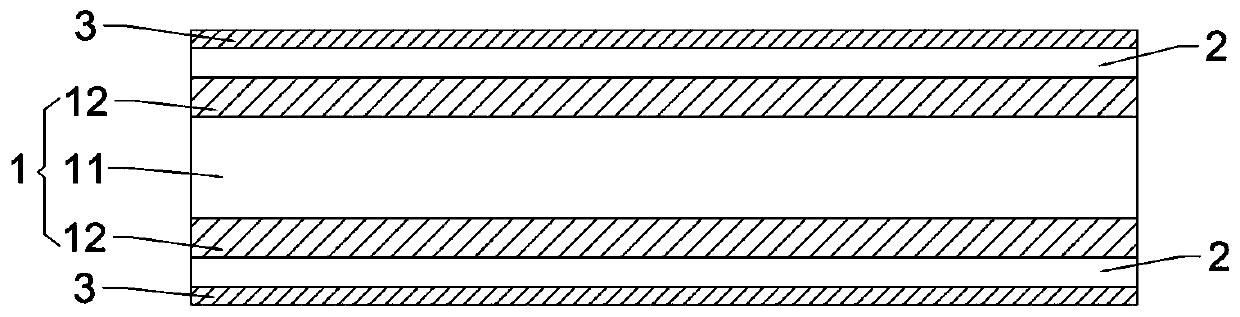

[0028] as attached figure 1 As shown, this embodiment provides a paper current collector, which includes a multilayer structural fiber layer 1, a metal coating 2 and a carbon base coating 3, and the multilayer structural fiber layer 1 includes at least one layer of nanocellulose base paper layer 11, both sides of the nanocellulose base paper layer 11 are provided with a composite paper coating 12; the side of the composite paper coating 12 away from the nanocellulose base paper layer 11 is provided with the metal coating 2. The side of the metal coating 2 away from the composite paper coating 12 is provided with the carbon base coating 3; the composite paper coating 12 includes nano-cellulose, inorganic fillers and nano-rubber additives. Wherein, the nano-cellulose is natural plant cellulose; the inorganic filler is calcium sulfate; the nano-rubber additive is styrene-butadiene latex; the carbon-based coating includes a carbon-based material and a polymer adhesive; the carbon-...

Embodiment 2

[0037] This embodiment provides a paper current collector, the structure of which differs from that of Embodiment 1 only in that the metal plating of the paper current collector is copper plating.

[0038] In addition, the difference between the preparation method of the paper current collector and Example 1 is that the preparation method is to vapor-deposit copper on the above-mentioned two-layer composite paper coating 12 by vacuum evaporation, which is far away from the nanocellulose base paper. On one side of the layer 11, two metal plating layers 2 each having a thickness of 1.25 μm were formed.

Embodiment 3

[0040] This embodiment provides a paper current collector, the structure of which differs from that of Embodiment 1 only in that: the nanocellulose is modified cellulose; the inorganic filler is calcium carbonate.

[0041] In addition, the difference between the preparation method of the paper-based current collector and Example 1 is that the preparation method is to transfer the aluminum-coated polyethylene terephthalate (Polyethylene Terephthalate, PET) The aluminum on the release film is transferred to the side of the above-mentioned two-layer composite paper coating 12 away from the nanocellulose base paper layer 11 to form two metal coatings 2 with a thickness of 1.25 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com