Preparation method and application of chiral Co-MOF/CoSR/PU core-shell composite material

A composite material, chirality technology, applied in the direction of material analysis, material analysis, material electrochemical variables, etc. by electromagnetic means, to achieve the effects of easy industrialization, improved conductivity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

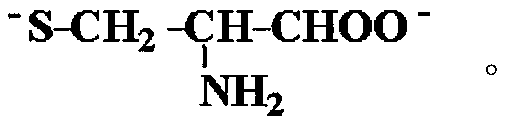

[0031] Example 1 A preparation method of a chiral Co-MOF / CoSR / PU core-shell composite material Dissolve 1.8mmol cobalt nitrate hexahydrate and 7mmol 2-methylimidazole in 12mL ethanol respectively, mix the above two solutions, and statically Placed for 24 hours, centrifuged, washed with ethanol for 3 times, the Co-MOF was prepared; 5 mL of 0.2 M L-cysteine aqueous solution was added to the prepared Co-MOF for blending, magnetically stirred for 1 hour, and the centrifugation was continued. After washing with ethanol for 3 times, drying at 85°C to constant weight, the chiral Co-MOF / CoSR composite material was prepared;

[0032] 0.4g of isophorone diisocyanate, 0.2g of chiral Co-MOF / CoSR composite material and 15mL of water / DMF mixed solvent with a volume ratio of 15 / 85 were blended, heated at 30°C for 1h, centrifuged, and the volume The ratio of 15 / 85 water / DMF was washed 3 times, and dried to constant weight at 90°C to obtain the chiral Co-MOF / CoSR / PU core-shell composite.

...

Embodiment 2

[0038] Example 2 Preparation method of a chiral Co-MOF / CoSR / PU core-shell composite material

[0039] Dissolve 2.0 mmol of cobalt nitrate hexahydrate and 8 mmol of 2-methylimidazole in 12 mL of ethanol respectively, mix the above two solutions, let stand at room temperature for 24 h, centrifuge and wash with ethanol three times to obtain Co-MOF; Add 6mL, 0.2M L-cysteine aqueous solution to the Co-MOF for blending, magnetically stir for 1h, continue to centrifuge, wash with ethanol three times, and dry to constant weight at 85°C to prepare chiral Co-MOF / CoSR composite Material;

[0040] 0.5g of isophorone diisocyanate, 0.2g of chiral Co-MOF / CoSR composite material and 18mL of water / DMF mixed solvent with a volume ratio of 15 / 85 were blended, heated at 35°C for 1h, centrifuged, and the volume The ratio of 15 / 85 water / DMF was washed 3 times, and dried to constant weight at 90°C to obtain the chiral Co-MOF / CoSR / PU core-shell composite.

[0041] The structure and properties of ...

Embodiment 3

[0042] Example 3 Preparation method of a chiral Co-MOF / CoSR / PU core-shell composite material

[0043] Dissolve 2.2 mmol of cobalt nitrate hexahydrate and 9 mmol of 2-methylimidazole in 15 mL of ethanol respectively, mix the above two solutions, let stand at room temperature for 24 h, centrifuge, and wash with ethanol for 3 times to obtain Co-MOF; Add 8mL, 0.2M L-cysteine aqueous solution to the Co-MOF for blending, magnetically stir for 1h, continue to centrifuge, wash with ethanol three times, and dry to constant weight at 85°C to obtain a chiral Co-MOF / CoSR composite Material;

[0044] Blend 0.6g of isophorone diisocyanate, 0.3g of chiral Co-MOF / CoSR composite material and 20mL of water / DMF mixed solvent with a volume ratio of 15 / 85, heat at 40°C for 1h, centrifuge, and the volume The ratio of 15 / 85 water / DMF was washed 3 times, and dried to constant weight at 90°C to obtain the chiral Co-MOF / CoSR / PU core-shell composite.

[0045] The structure and properties of the SR, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com