Zirconium-contained high-hardness, corrosion-resistant, high-entropy alloy material and preparation method thereof

A high-entropy alloy and high-hardness technology is applied in the field of high-hardness corrosion-resistant high-entropy alloy materials and their preparation, which can solve the problems of low room temperature hardness and restrict the application of structural materials, and achieve the effect of improving mechanical properties and good corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A zirconium-containing high-entropy alloy in this embodiment is composed of five elements: Co, Cr, Fe, Ni and Zr, wherein the molar ratio of Co:Cr:Fe:Ni:Zr is 1:1:1 :1:0.48.

[0027] First, high-purity cobalt, chromium, iron, nickel and zirconium blocks are used as raw materials, and the surface oxide scale is removed by mechanical grinding, and then put into absolute ethanol for ultrasonic cleaning and dried to obtain pure metal after cleaning. Raw materials: The cleaned metal raw materials are accurately weighed according to the molar ratio of Co:Cr:Fe:Ni:Zr 1:1:1:1:0.47. Put the weighed raw materials into the electric arc melting furnace in order of melting point from low to high, among which the element with the lowest melting point is placed at the bottom, the element with the highest melting point is placed at the top, and the pure titanium ingot is placed in the middle In a water-cooled copper crucible, close the furnace door after placing it; vacuumize the samp...

Embodiment 2

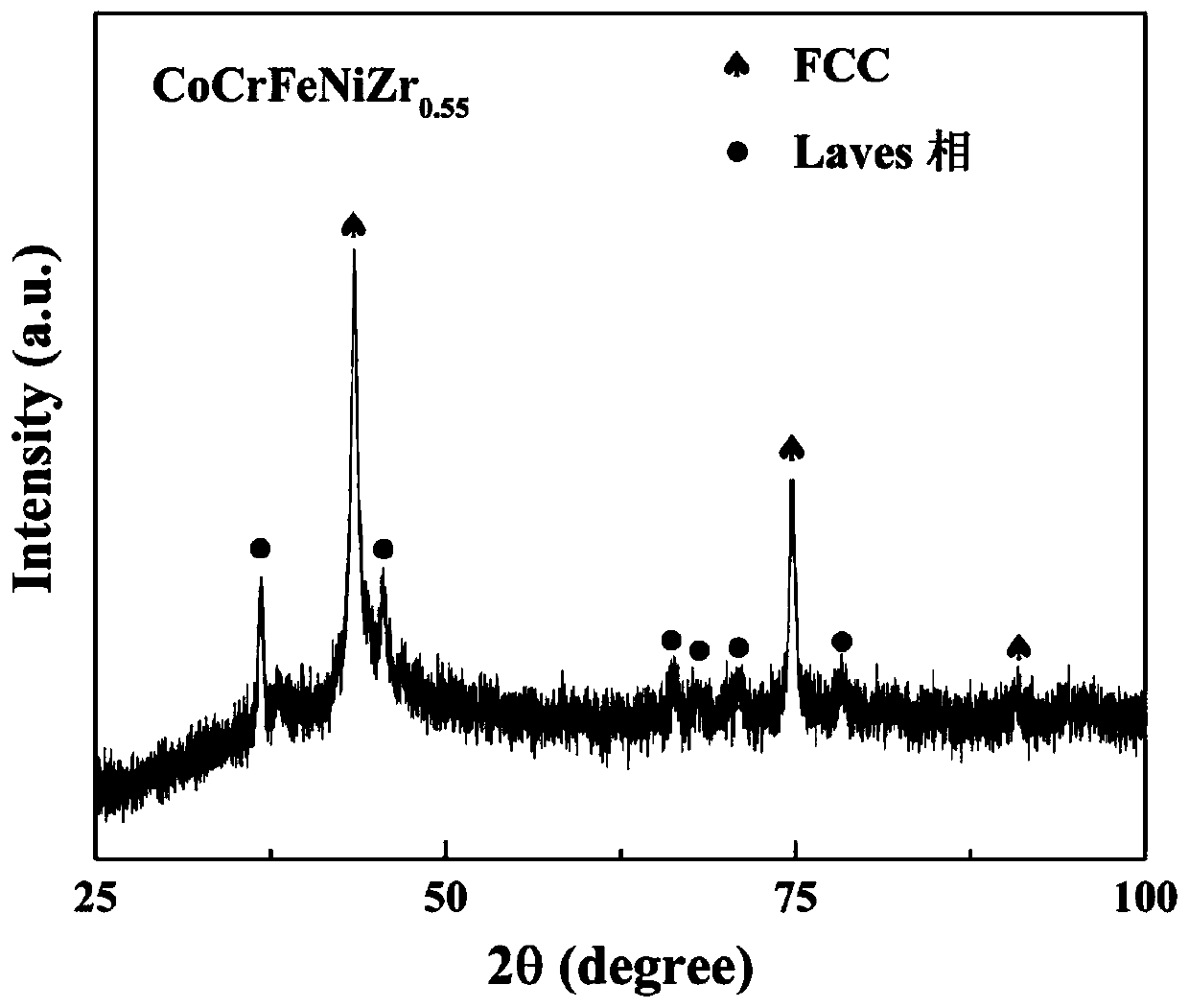

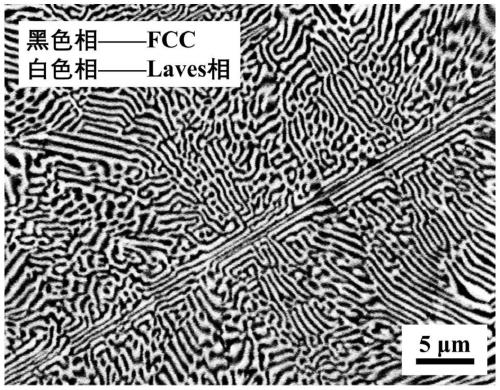

[0030] A zirconium-containing high-entropy alloy in this embodiment is composed of five elements: Co, Cr, Fe, Ni and Zr, wherein the molar ratio of Co:Cr:Fe:Ni:Zr is 1:1:1 :1:0.55.

[0031] First, high-purity cobalt, chromium, iron, nickel and zirconium blocks are used as raw materials, and the surface oxide scale is removed by mechanical grinding, and then put into absolute ethanol for ultrasonic cleaning and dried to obtain pure metal after cleaning. Raw materials: The cleaned metal raw materials are accurately weighed according to the molar ratio of Co:Cr:Fe:Ni:Zr 1:1:1:1:0.55. Put the weighed raw materials into the electric arc melting furnace in order of melting point from low to high, among which the element with the lowest melting point is placed at the bottom, the element with the highest melting point is placed at the top, and the pure titanium ingot is placed in the middle In a water-cooled copper crucible, close the furnace door after placing it; vacuumize the samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com