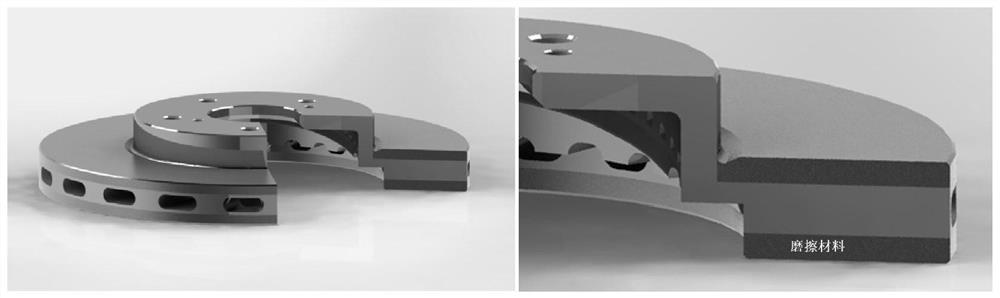

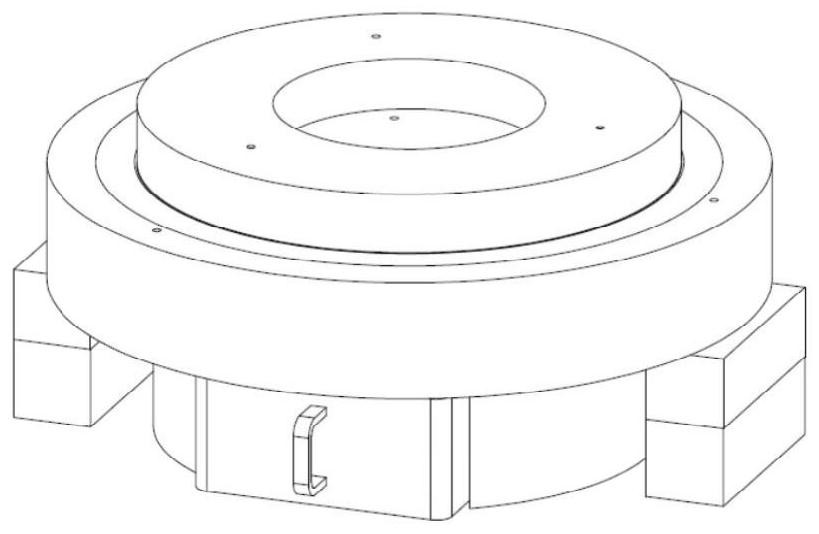

A light wear-resistant aluminum-based powder metallurgy composite automobile brake disc and its preparation method

An aluminum-based composite material and automobile braking technology, applied in the direction of brake discs, brake types, brake components, etc., can solve the problems of failure to meet braking requirements, high energy consumption of brake discs, and non-wearable brake discs and other issues, to achieve the effect of reducing weight, improving mechanical properties, wear resistance and braking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

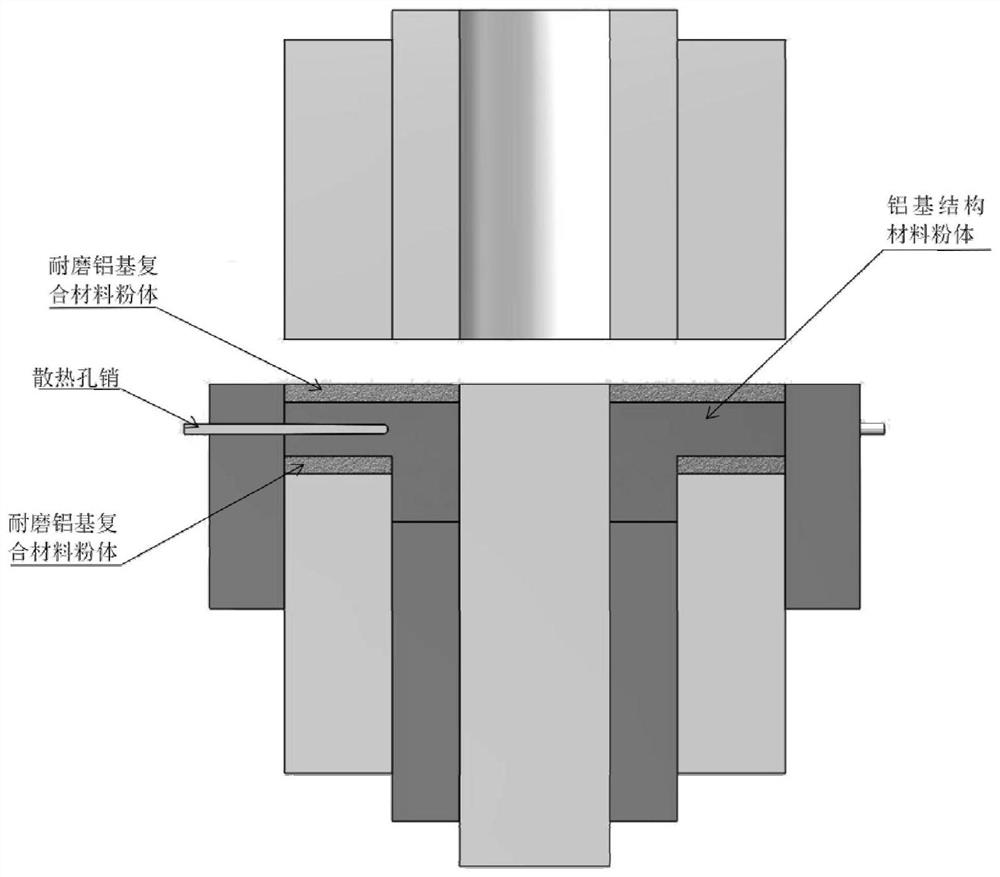

[0045] A method for preparing an aluminum-based powder metallurgy composite automobile brake disc of the present embodiment is implemented according to the following steps: 1. 4% Fe, 4.5% Cu, 0.2% Sr, 0.3% Ce, 40% SiC of SiC and 51% aluminum powder (above all are mass fractions) are added into mixer, mix 50min with the speed of 20r / min, obtain wear-resisting aluminum-matrix composite material powder; Two, 4% Fe, 4.5% Cu, 0.2% Sr, 0.3% Ce and 91% aluminum powder (the above are all mass fractions) are added to the mixer, and mixed for 40min at a speed of 20r / min to obtain the aluminum-based structural material powder; 3. Step The wear-resistant aluminum-based composite material powder and aluminum-based structural material powder treated in the first and second treatments are respectively filled into the corresponding positions of the cold-pressing mold, and inserted into the heat dissipation hole pins, and cold-pressed at a pressure of 200MPa and a pressurization rate of 2mm / s...

Embodiment 2

[0048] A method for preparing an aluminum-based powder metallurgy composite automobile brake disc of the present embodiment is implemented according to the following steps: 1. 2% Fe, 6.6% Si, 0.1% Sr, 0.3% Mg, 50% SiC of SiC and 41% aluminum powder (above all are mass fractions) are added into mixer, mix 40min with the speed of 20r / min, obtain wear-resisting aluminum-matrix composite material powder; Two, 3% Fe, 3.5% Cr, 0.5% Ce and 93% aluminum powder (the above are all mass fractions) are added to the mixer, and mixed at a speed of 20r / min for 45min to obtain the aluminum-based structural material powder; Wear-resistant aluminum-based composite material powder and aluminum-based structural material powder were respectively filled into the corresponding positions of the cold-pressing mold, and inserted into the heat dissipation hole pins for cold-pressing. The pressure was 250 MPa, and the pressurization rate was 1mm / s. The time is 20s; 4. Sinter the automobile brake disc gre...

Embodiment 3

[0053] A method for preparing an aluminum-based powder metallurgy composite automobile brake disc of the present embodiment is implemented according to the following steps: 1. 2% Fe, 1.5% Cr, 0.5% Ce, 0.1% Mg, 70% SiC of SiC and 25.9% of aluminum powder (above all are mass fractions) are added into the mixer, mix 40min with the speed of 20r / min, obtain wear-resisting aluminum matrix composite material powder; Cr, 0.5% Ce and 93% aluminum powder (the above are all mass fractions) are added to the mixer, and mixed at a speed of 20r / min for 45min to obtain the aluminum-based structural material powder; Wear-resistant aluminum-based composite material powder and aluminum-based structural material powder were respectively filled into the corresponding positions of the cold-pressing mold, and inserted into the heat dissipation hole pins for cold-pressing. The pressure was 250 MPa, and the pressurization rate was 1mm / s. The time is 20s; 4. Sinter the automobile brake disc green body ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com